SOURCE TO PAY

What is Source to Pay – A Guide to Source-to-Pay (S2P) Process [2025]

Table of Contents

Introduction to Source to Pay

Source to Pay or S2P in procurement is defined as a process that streamlines finding, evaluating, negotiating, and contracting with suppliers to efficiently source, order, and pay for goods and services. It involves end-to-end integration with procurement platforms or systems to ensure procedural compliance to manage spend effectively. The Source-to-Pay process is carried out to enable accurate spend analysis, evaluate supplier performance and collaboration to drive business value.

Simfoni.com Tweet

S2P (Source to Pay) is a cycle that begins with the identification of suppliers or vendors and concludes with the payment of products and services. Floating a proposal, competitive bidding, contract negotiation, and other actions, depending on the industry, are used to connect these two ends.

Businesses use S2P to obtain a market edge and to connect all vendors and suppliers into a single platform. As a consequence, businesses will be able to use a single platform for both external and internal activities, resulting in improved performance.

Let’s look at how Source to Pay plays a part in determining a company’s profitability and how it may be improved.

What is S2P in Procurement?

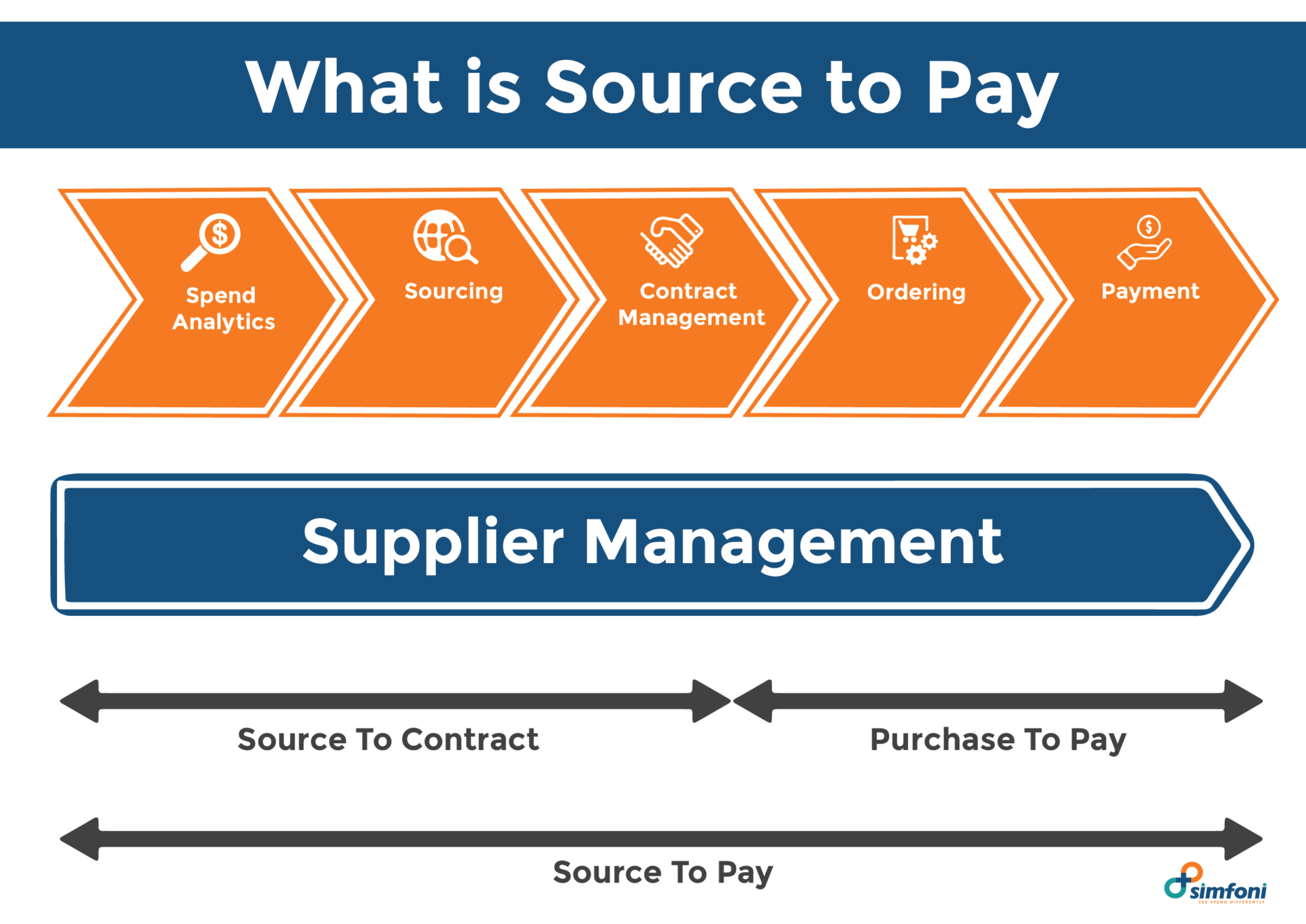

The full end-to-end procurement process is referred to as source-to-pay, or S2P. It encompasses all processes, including spend management, strategic sourcing, and vendor management, as well as buying, procurement management, and accounts payable.

S2P, or Source to Pay, is a cycle that begins with the identification of suppliers and concludes with the payment of products and services, with many actions connecting these two endpoints.

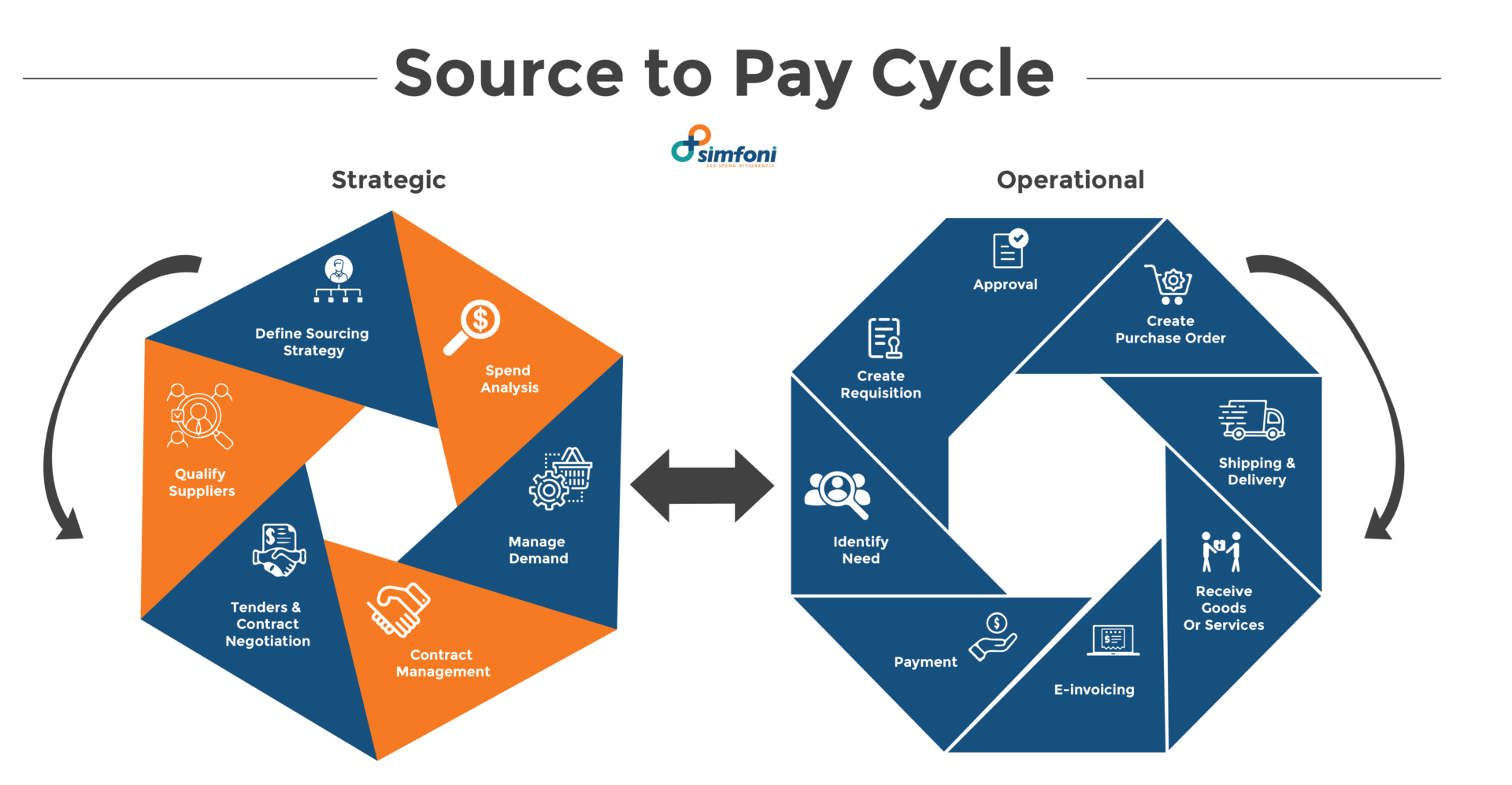

Source-to-Pay Cycle

S2P is a procedure that begins with locating, negotiating, and contracting with a product provider and ends with the final payment for those items. To increase procurement efficiency, S2P software employs technology, big data, and digital networks.

Best-in-class firms combine purchases across business divisions to increase performance, provide superior spend insight, and produce business value, rather than treating procurement as a series of isolated chores. Those who implement a source-to-pay platform include :

- Increased procurement visibility leads to larger sourcing savings.

- To get to signed contracts faster, combine essential procedures onto a single platform.

- Improve compliance with procedures, regulations, and contracts

- Improve trading partner collaboration, trust, and spending

- Improve your pricing and forecasting accuracy by negotiating better terms.

Read More:- Guide to eSourcing Software & Tools by Simfoni’s Procurement Professionals

What does Source to Pay mean?

The sourcing and procurement process of locating, negotiating, and employing suppliers for their products or services, culminating in payment of those goods or services, is known as source-to-pay (S2P). Big data and digital technology are used in S2P software to achieve the most effective procurement process possible.

Source to Pay Life Cycle

The S2P process takes time, and sourcing and procurement teams will squander time if they don’t plan. Let’s look at how a typical source-to-pay life cycle fits into a procurement year.

1. Locating Vendors

The first phase in the source-to-pay life cycle is to do extensive market research to find potential suppliers. Requests for Information (RFIs), Requests for Proposals (RFPs), and maybe Requests for Quotes will be sent out during this stage (RFQs). Simfoni provides advanced RFX templates for e-sourcing that make gathering and analyzing vendor data easy. Some sourcing teams may employ e-auctions in their source to pay life cycle in addition to obtaining information from vendors.

2. E-Auctions

Sourcing teams utilize e-auctions to get the greatest bargains on raw materials and merchandise. E-auctions are strikingly similar to traditional auctions. Suppliers are bidding on their goods and services and trying to outbid one another in this situation. The goal of this procedure is to discover not only dependable but also reasonably priced providers. Simfoni has created one of the most popular reverse online auction applications.

Market. Easy-to-use, real-time bidding, and automatic score aggregation help your vendor selection process go more smoothly. Our program helps you save anywhere from 18 to 40% on your costs.

3. Supplier Evaluation/Vetting

With the various RFX information supplied back by suppliers and the e-auction results, sourcing teams may start vetting the numerous vendors to locate acceptable matches. Sourcing is a delicate balancing act. The raw materials must be reasonably priced so that the firm may profit when the product is manufactured. Supplier evaluation takes into account more than simply quality; it also considers price, minimum order quantities, and delivery periods, among other things. Negotiations might commence after a suitable provider has been located.

4. Contracting and Negotiating

The sourcing team may choose up to three vendors to work with after reviewing the material provided by the various providers. This is the stage of contracting and negotiating. Because companies are constantly seeking methods to reduce manufacturing costs across the supply chain, one place where costs may be cut is at the sourcing stage. The purchase price of items can be lowered if bigger volumes are sourced. Contracts can be issued once pricing and order quantities have been decided. You can expedite the contractual process, keep documents in one single location, and manage everything from a consolidated interface due to Simfoni’s contracting software.

5. Payment and Delivery of Goods

Goods delivery and payment are the last steps in the source-to-pay life cycle. This is the final step. Depending on the demands of the company, a supply schedule and automated payment system may be set up to ensure that raw materials are supplied on time and without disrupting production throughout the year.

6. Use Automation Software to Simplify Source to Pay Process

When seeking suppliers for specific items manually, the procedure can be arduous, time-consuming, and inaccurate. Businesses and organizations utilize a source-to-pay process to select suppliers, source, purchase, and pay for products and services. Procure to pay operations must be handled with attention because of their linked components.

All procure-to-pay phases are included in a comprehensive source-to-pay process, as well as vendor selection and strategic sourcing at the start of the P2P process, providing you complete expenditure visibility from vendor onboarding through payment decision. Organizations, particularly large and complicated ones, are automating source-to-pay processes by adopting automation software nowadays, due to the quick speed of company operations and the changing face of procurement.

All procure-to-pay phases are included in a comprehensive source-to-pay process, as well as vendor selection and strategic sourcing at the start of the P2P process, providing you complete expenditure visibility from vendor onboarding through payment decision.

Organizations, particularly large and complicated ones, are automating source-to-pay processes by adopting automation software nowadays, due to the quick speed of company operations and the changing face of procurement. A complete source to pay automation solution will provide a wide range of capabilities in procurement, sourcing, and accounts payable, as well as the following advantages :

- Contract lifecycle management and strategic sourcing to support vendor relationships and negotiate.

- Purchase requisitions and approvals are supported by electronic procurement processes. This helps with product and service ordering and delivery.

- Automation provides unrivaled flexibility in terms of creating purchase orders and sending them to vendors.

- Automation encourages invoice reception, validates and connects purchase orders to invoices, and manages non-PO-based invoices and invoice exceptions procedures.

- Automated payment processing and reconciliation, working capital efficiency, and payment discount management are all benefits of automation.

- You may reap the full benefits of automation by using automation software from a specialized provider. These include supplier information management, which allows you to examine and understand a provider’s past and stability, reducing supply chain risks.

7. Simfoni’s Procure to Pay Automation Solutions

Simfoni’s ideology is based on data-driven ideas that centralize spending transparency and processes. Simfoni also provides electronic procurement, Spend Analytics, AP analytics, Procurement Analytics, and tail spend automation, among other procure-to-pay solutions.

Using Simfoni’s seamless integration capabilities, the centralized core complements and grows into all source-to-pay stages. The following are some of the benefits of using Simfoni’s source to pay automation solutions :

- Purchase orders are created faster and delivered faster for approval.

- Process automation reduces ordering and requisition mistakes dramatically.

- Cost savings due to procurement workers being freed up to focus on other mission-critical business operations.

- Improved financial insight into your business operations and better expenditure visibility.

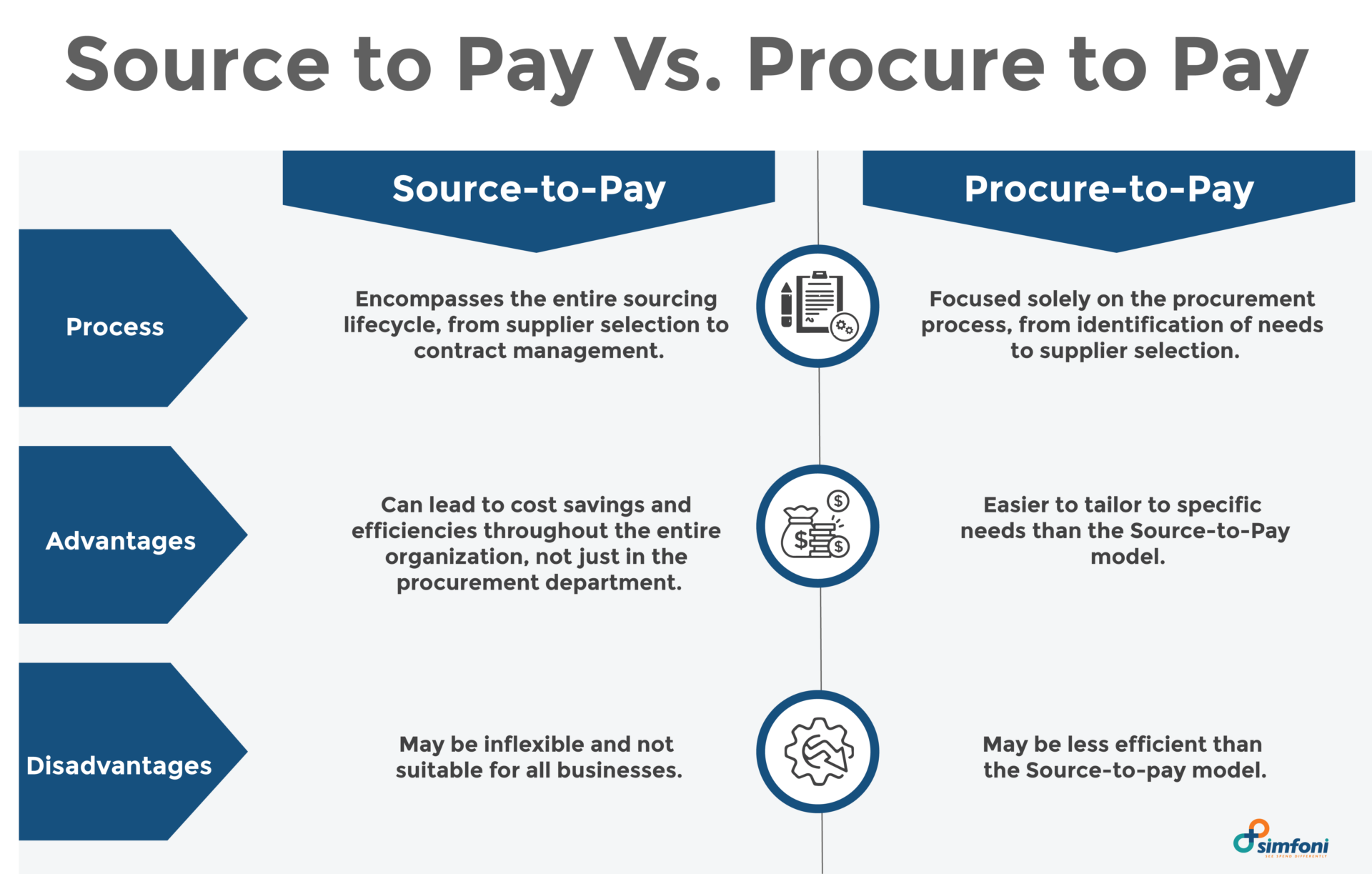

Source to Pay vs. Procure to Pay: What’s the Difference?

With the aforementioned concept in mind, it’s only logical to mistake Source to Pay with Procure to Pay. They are not, however, the same. Source to Pay is, in reality, a perfected form of the Procure to Pay procedure.

Let’s start with the usual Procure to Pay procedure to explore the distinctions between the two :

- A person sees a need for products or services and begins the procurement process.

- A purchase request is created, which includes all of the specifications and requirements, and it is distributed for evaluation and approval.

- Once the requisition is authorized, a purchase order is created, reviewed, and submitted to the vendor.

- The items or services are provided by the vendor, and the receivables are checked internally.

- After the products and services are delivered, the vendor issues an invoice that is cross-referenced with the purchase order and receipt paperwork.

- After the products and services are delivered, the vendor issues an invoice that is cross-referenced with the purchase order and receipt paperwork.

- The accounts payable (AP) division issues the payment and records the transaction on the ledger when the invoice is approved.

Compare and contrast the above with the Source to Pay method, which follows:

- A person sees a need for products or services and begins the sourcing process. It might also be sparked by a lack of improved price terms on already available goods and services.

- The company uses data-driven techniques to scour the industry and shortlist providers based on characteristics including reputation, market trends, and service history. The selected suppliers are added to the vendor master database and receive all sourcing messages.

- Companies create all RFx material, such as RFQs (Requests for Quotes), RFIs (Requests for Information), RFPs (Requests for Proposals), and other similar documents, which are then reviewed, authorized, and publicized.

- Once the specifications have been published, interested suppliers can submit bids.

- All proposals are assessed, and the contract is given to the provider that checks the most boxes.

- After selecting a vendor, the parties engage in contract negotiations to determine the contract’s terms, price, and length.

- The contract is examined and signed when it has been agreed upon and finished.

- Payments are paid according to contract conditions, and procurement continues as usual.

As can be seen from the above, Source to Pay provides more exposure to the company without placing it at risk, as most decisions are based on data-driven insights. It also takes into account proactive optimization, such as vendor onboarding, contract management, and bidding, to ensure fairness throughout strategic sourcing.

What is the significance of the source to pay?

Automated source-to-pay eliminates rogue spending, decreases supplier risk, improves the procurement process, and saves money. The source-to-pay cycle may be digitally transformed to help businesses maximize ROI and establish a strong supplier network. Here are five major advantages of digitizing the S2P process.

- Streamline procurement procedures — Procurement software connects the whole business, allowing requisitions to be sought and authorized faster, relevant vendors to be chosen based on data, and POs to be created and sent to suppliers… Everything is done online and is easily traceable.

- Costs of invoice processing can be cut by up to 80%. – Going paperless saves time and money, allowing businesses to focus their resources on more strategic objectives rather than monotonous operations that might be automated.

- Obtain complete visibility – A P2P system gives real-time insight throughout the supply chain, allowing buyers and suppliers to monitor invoice progress.

- Improve exception management — Because most bills are processed straight through, exceptions may receive the attention they deserve and be handled more quickly.

- Improve supplier relationships — By using the supplier portal, suppliers can find out when they will be paid, which provides them with the knowledge they need to make better decisions. Faster settlement of invoice exceptions and disputes generates goodwill and gives buyers more visibility.

- Utilize negotiation leverage – When suppliers are confident in their payment status, they may be ready to provide conditions that are more favorable to buyers while still ensuring that suppliers receive the money they require to expand their business.

Capture data for enhanced decision-making — P2P systems with strong on-demand reporting capabilities are ideal. Companies may have more control over cash flow and working capital by utilizing the real-time and historical data supplied.

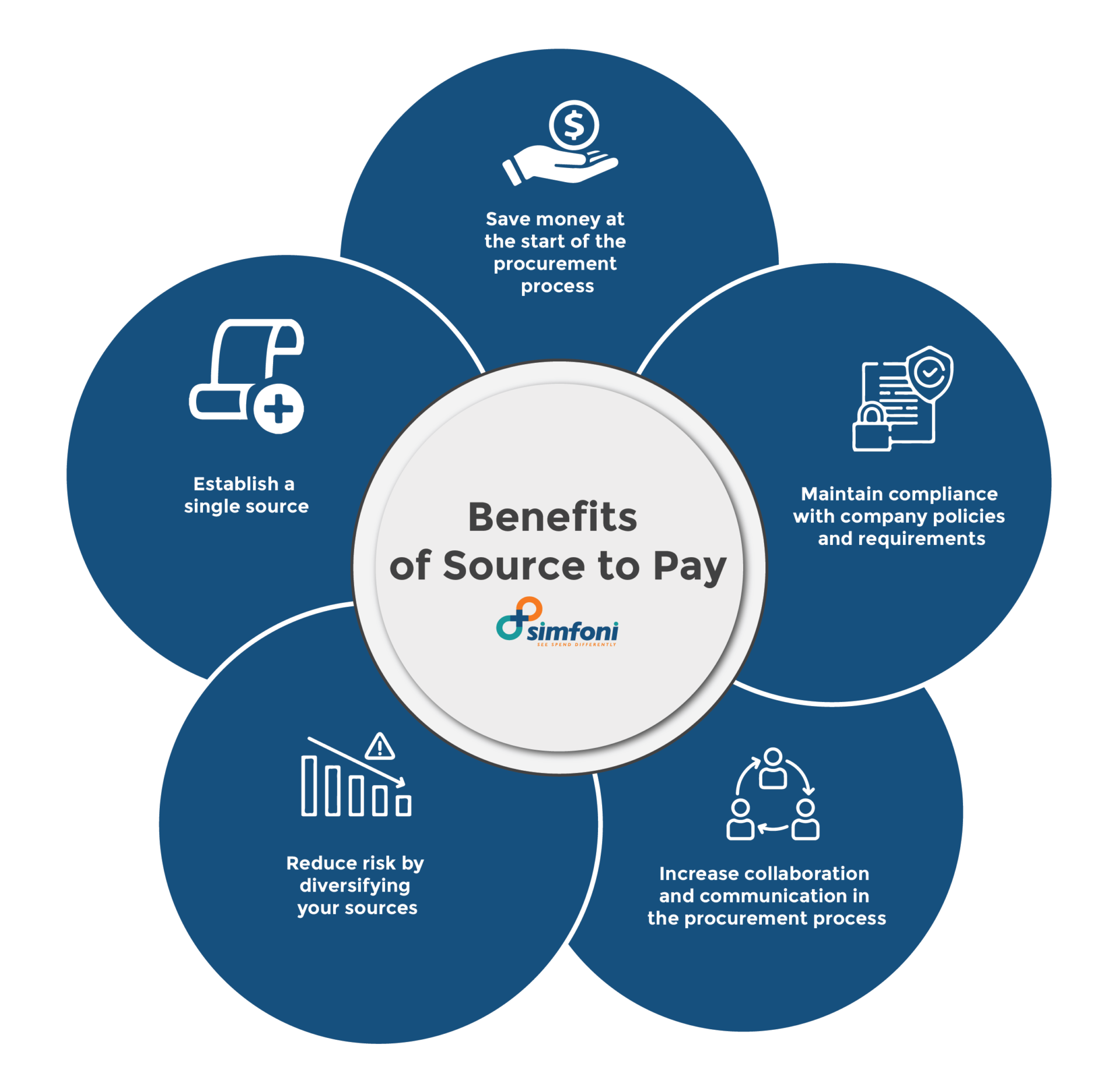

Benefits of Source to Pay Platform

S2P standardizes internal and external business processes, reducing the need for numerous ERP software, as previously stated. As a consequence, increased efficiency and performance are achieved. To further explain these benefits, consider the following arguments in support of an integrated Source to Pay platform :

1. Save money at the start of the procurement process.

While the P2P concept works with existing vendors, S2P works with all suppliers. You establish the groundwork for fair and competitive pricing by opening up the market. This will save you money straight now. When you add automation to the mix, your expenses will be even lower!

2. Maintain compliance with company policies and requirements

Businesses are less likely to suffer problems while acquiring products and services since S2P entails the creation of a contract in which the terms and conditions are put out and agreed upon. Furthermore, the contract would be compliant with corporate standards and regulations for demand and supply alignment.

3. Increase collaboration and communication in the procurement process

Employees and vendors will have a common language to communicate with one other if they are on the same platform. Throughout the S2P process, such empowerment will enable more productive and meaningful connections.

4. Reduce risk by diversifying your sources.

S2P reduces your reliance on a single vendor or supplier, spreading risk and ensuring supply chain continuity in the event of a breakdown. Furthermore, it is more secure and robust than its peer-to-peer cousin.

5. Establish a single source

The procurement process is standardized, and all parties are connected on the same platform.

As a result, it serves as a single point of truth for all procurement-related data and facilitates well-informed choices.

When Should a Company Use Source to Pay?

The S2P (source to pay) approach efficiently achieves these aims when firms need to locate new vendors that provide better terms, cheaper costs, or new commodities that current suppliers do not supply.

What Are S2P Software’s Benefits?

The bottom line is that organizations that implement the appropriate digital technologies will have a competitive edge over those that do not. Source-to-pay solutions have several advantages.

- Analysis of live data

- Potential vendors’ offers are more competitive.

- Improved review and qualification of vendors

- Negotiations and eAuctions over the internet

- Savings in the long run

- Streamlined workflow and process automation

- Automated expenditure analysis by vendor and product or service category that is more accurate

- Processing costs are lower.

- Cash flow analysis is simplified.

- Streamlined business procedures

- Supply chain and expenditure management that is more efficient

- More efficient risk management

- Supplier data that is easier to track

- Overall better user experience

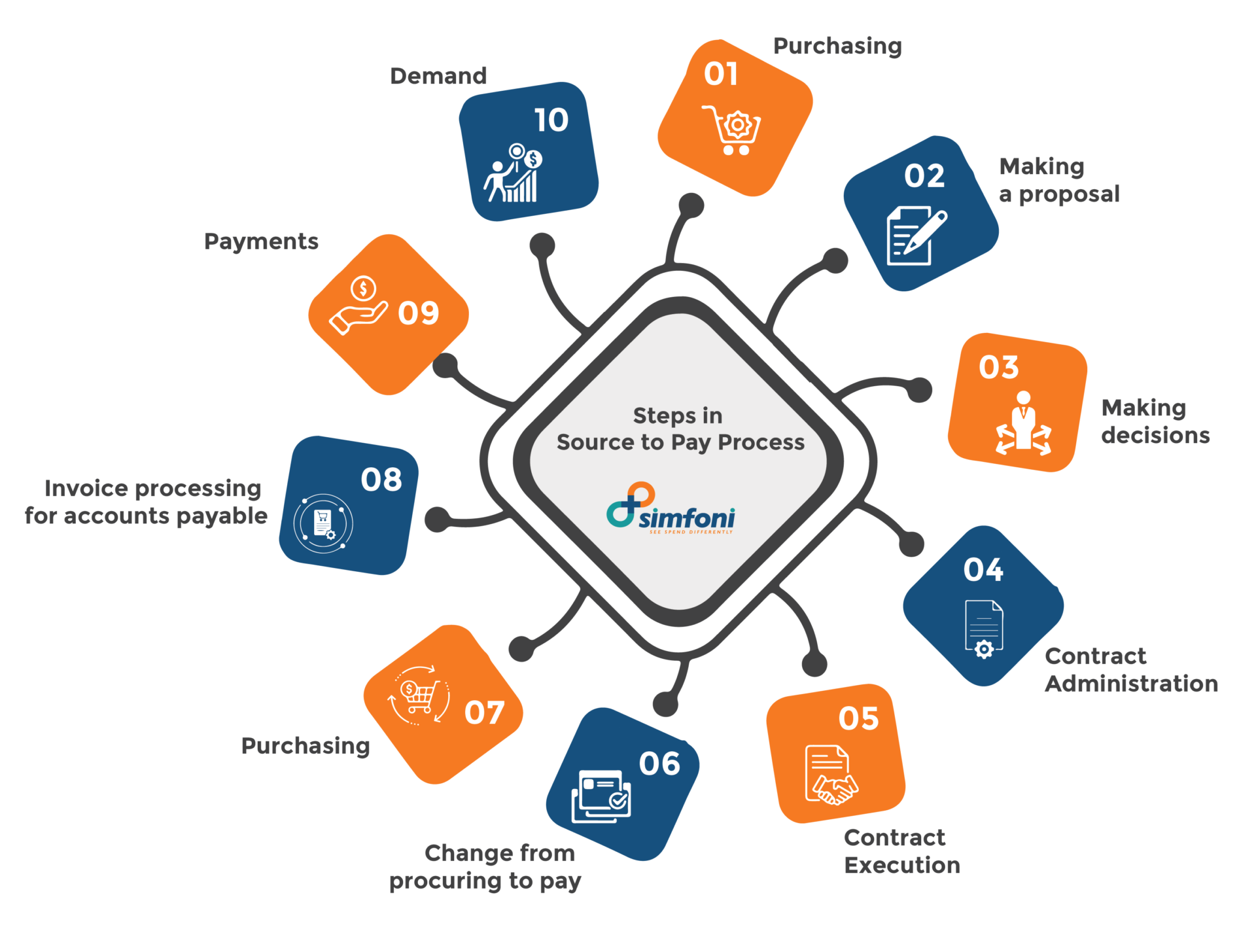

What are the Steps in the Source to Pay Process?

S2P is a digital route that leads to e-procurement, which is a phrase for offering online procurement solutions.

The steps from source to payment are :

- Purchasing

- Making a proposal

- Making decisions

- Contract administration

- Contract execution

- Change from procuring to pay

- Purchasing

- Invoice processing for accounts payable

- Payments

- Demand

The business must require a service or product. Alternatively, demand might be fueled by a desire for a cheaper price or better conditions.

1. Purchasing

Potential supply chain vendors are identified and assessed in this stage. For eSourcing software systems that manage vast volumes of data on previous expenditure, industry trends, and organizational goals can be used to implement this sourcing approach. Vendors who meet basic requirements can be cataloged as part of a smooth onboarding process.

2. Making a proposal

RFx papers are created, and supplier answers are received and kept on an eSourcing site. Requests for information (RFIs), proposals (RFPs), and quotations are examples of RFx documents (RFQs).

3. Making decisions

Suppliers must be evaluated in the fourth phase. Some will be selected, while others will not.

4. Contract administration

After that, you must enter successful vendors into a supplier management database and negotiate price and contract conditions.

Contracts are kept for the duration of the contract lifecycle and then for as long as is necessary to comply with tax and company-related document preservation requirements.

5. Signing a contract

Once the contract conditions have been agreed upon, it’s time to finish and sign the contract paper.

6. Change from procuring to pay

It’s time to hand the baton to the procurement team when the contract is signed. The source-to-pay procedure includes procure-to-pay.

7. Procurement

The procurement department will be in charge of all purchase orders and purchase requisitions, as well as vendor follow-up.

8. Invoice processing for accounts payable

Vendor invoices will be captured and processed by accounts payable, which will include screening vendors for authenticity, verifying invoices, matching vendor invoices with purchase orders and receiving documents, obtaining invoice approvals, and generating some accounting reports.

9. Payments

Accounts payable complete the source-to-pay process by making and reconciling payments and informing vendors about the status of their payments.

Read More:- Comprehensive Guide to Procurement Management.

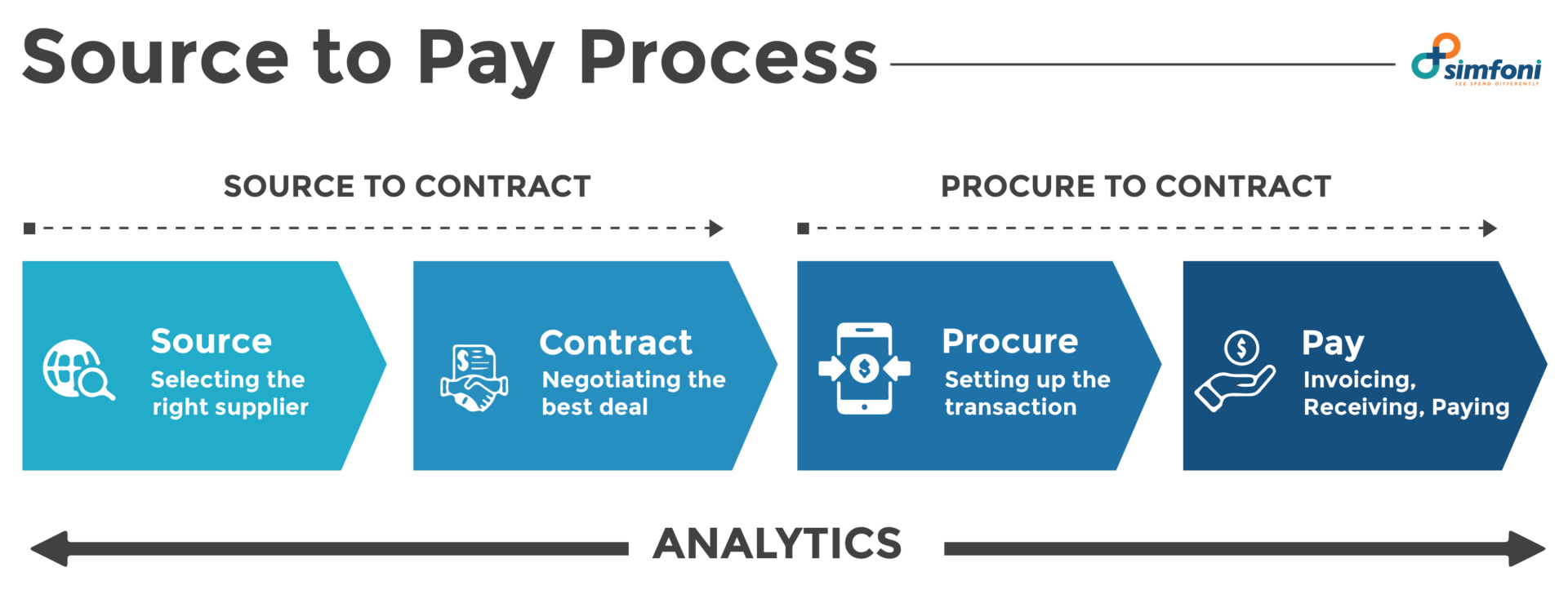

Procure-to-Pay and Source-to-Pay Comparison

To begin, while the P2P and S2P processes are similar in many respects, there are some distinctions, the most notable of which is that S2P begins one step earlier than P2P, with the sourcing of commodities. The procure-to-pay process normally starts with a request for goods and services and concludes with payment to the vendor by the accounts payable team.

It goes a step further with a source to pay. Strategic sourcing becomes a part of the process with S2P, ensuring that the best vendors are chosen and that contracts are negotiated with them. Internal controls are improved, supply chain efficiency is improved, and vendor relationship management is simplified.

Automated Source-to-Pay

The next stage for businesses is to select the greatest automation targets inside their processes. Organizations may achieve this by assessing their present level of automation and comparing it to what is theoretically possible for each job in the source-to-pay process. The value of narrowing each gap may then be calculated.

The quantity of work that can be automated as well as the expected gains in compliance, cycle durations, and payment conditions connected with each stage will provide this value. Any benefits must be weighed against the expense and difficulty of installing appropriate technology. Complex machine-learning technologies and cognitive agents, for example, are likely to be more difficult and expensive to install than robotic process automation and smart workflow solutions.

The growing image of the end-to-end process will allow you to compare the relative advantages of addressing each stage against the relative expense and complexity of automating those phases.

Understanding the Source-to-Pay Cycle

S2P is a procedure that begins with locating, negotiating with, and contracting with a product provider and ends with ultimate payment for those items.

To increase procurement efficiency, source to pay software uses technology, big data, and digital networks. Best-in-class firms combine purchases across business divisions to increase performance, provide superior spend insight, and produce business value, rather than treating procurement as a series of isolated chores. Those who implement a source-to-pay platform include :

- Increased procurement visibility leads to larger sourcing savings.

- To get to signed contracts faster, combine essential procedures onto a single platform.

- Improve compliance with procedures, regulations, and contracts

- Improve trading partner collaboration, trust, and spending

- Improve your pricing and forecasting accuracy by negotiating better terms.

Source to Pay Procedures

The source-to-pay procedure isn’t entirely separate from the procurement process. Instead, e-procurement is the result of a digital journey. This is a typical path for that journey:

- There must be a need for a service or product first. Alternatively, demand might be fueled by a desire for a cheaper price or better conditions.

- Sourcing: This stage involves locating and evaluating possible supply chain providers. This sourcing method may be implemented with the use of software systems that can manage enormous volumes of data on previous spending, industry trends, and corporate objectives. Vendors who meet basic requirements can be cataloged in a smooth onboarding process.

- RFx papers are gathered to prepare a bid. Information requests, proposals, and quotations are examples of these items.

- Decision-making: Candidates must be reviewed in the fourth phase. Others will not be picked.

- Contract management: After that, enter successful vendors into a supplier management database and negotiate price and contract conditions.

- Contract signing: Once the provisions of a contract have been agreed upon, it’s time to seal the deal and sign the contract.

- Pass the baton to the procurement team: After the contract is signed, the procurement team will be in charge of all purchase orders, invoicing, and payments.

What is the difference between source-to-pay and procure-to-pay?

Due to the many similarities between procure-to-pay and source-to-pay, many individuals find it difficult to recognize the nuances that help to separate the two processes. We’ll look at these distinguishing characteristics further on.

Difference 1: The First Step

The beginning phase of each process is undoubtedly the most significant distinction between procure-to-pay and source-to-pay procedures.

The procure-to-pay process starts with a request for specific raw materials, commodities, or services, but the source-to-pay process begins far earlier with a search for new vendors. This leads to the next discernible difference.

Difference 2: The Key S2P Aspect Source-to-pay includes an intrinsic element of strategic sourcing that the purchase-to-pay process does not have.

Strategic sourcing is a broad element of S2P that entails finding the best vendors, assessing them, and then contracting with them.

Difference 3: Each Process’ Goals

The last distinction between procure-to-pay and source-to-pay is their goals. Procure-to-pay methods are suitable for obtaining products and services from certified and known providers. These vendors are typically already familiar with the organization’s setup and specialized procurement requirements.

Businesses use the source-to-pay method when they require new suppliers who can provide cheaper pricing, better terms, or even new items that their current vendors can’t provide. This is where the S2P technique shines.

What is the process of going from source to pay?

The process of procuring raw materials, commodities, and/or services, as well as negotiating and executing contracts with those suppliers, is referred to as source-to-pay. Purchase orders (Pos) are subsequently sent to vendors via procurement. Receiving puts the Goods Receipt into the buying system or ERP, and accounts payable (AP) gets an invoice from the supplier after the order has been completed and received. The invoice is transmitted directly to the ERP or financial application for payment when AP matches the invoice to the PO and the Goods Receipt.

Automation Opportunities in the Source-to-Pay Process

Automation from procurement through payment isn’t a novel notion. Traditional procurement software concentrated solely on data storage, leaving little room for fragmented procedures or excessive complexity. Automation, on the other hand, is responsible for both tactical and strategic buying.

However, identifying activities that are suitable for automation is the most difficult aspect of adopting procure-to-pay automation. The following are the top five automatable procure-to-pay procedures.

1. Purchasing Request

It’s just not feasible to manually evaluate each purchase request for correctness and compliance with corporate standards and regulations. Purchase requests will be validated by cross-checking data against specified standards, and purchase requests will be rejected if the information is missing, inconsistent, or insufficient.

2. Purchase Order

When processing a purchase order, double-check that the information contained in the PO is correct. Manual purchase order methods are inefficient and prone to errors. In the vast majority of situations, they raise audit flags.

By automating procedures like creating Pos, drafting contracts, contacting stakeholders, dispatching Pos, receiving items, and processing payments, automation will enable a more orderly PO processing.

3. Approval of Purchase Invoice

Missing goods receipts and Pos, out-of-policy spending, late submissions, error-ridden spreadsheets, and insufficient visibility of spend are all common characteristics of manual invoice administration. It’s no surprise that manual invoice processing causes payment delays and compliance difficulties.

Purchase-to-pay digital systems may automate the complete invoice management process. Individual invoices, for example, are automatically compared against specified rules and accessible Pos and goods receipts, even when they are kept in various systems. Digital invoice processing offers several benefits, ranging from touch-free auto-approval of conventional low-value bills to expanded capabilities via connections with finance and accounting software.

4. Managing Vendors

Screening, selecting, and compiling a shortlist of potential providers is a time-consuming procedure. In reality, a single vendor’s examination might easily take weeks.

procure-to-pay automation will collect and filter requests for quotes (RFQs), verify the information, and match it to required vendor profiles. In a single click, the best provider may be discovered and shortlisted depending on established rules.

5. Contract Administration

The work of monitoring current contracts, preserving copies of previous contracts, evaluating contracts, and assuring terms compliance is enormous. Even small to mid-sized organizations may find it challenging to manage all of this paperwork, let alone firms with many locations.

procure-to-pay automation may generate consistent purchase contracts depending on the products acquired automatically. In addition, a specified contract management loop will be triggered, which will evaluate and monitor contracts at regular intervals.

Read More:- Comprehensive Guide to Tail Spend Management.

Best Practices in Source to Pay

The phrase source-to-pay refers to an integrated process workflow that combines strategic sourcing and procurement with accounts payable (AP) and finance operations in the supply management sector. It’s a closed-loop process that, when standardized, integrated, and automated, allows procurement teams to manage the acquisition of products and services holistically to satisfy business objectives and fill company demands, as well as assure accurate payment remittance.

And, like other processes, it is supported by a set of best practices for ensuring effective and consistent execution across the company and supply chain, a robust strategy for knowledge management is required to achieve source-to-pay excellence. The industry’s best practices in those important areas are detailed in this paper.

Chief Procurement Officers (CPOs) and their procurement and procure-to-pay teams may be defined by specific performance metrics (e.g., savings targets, cash impact, and percentage of spend under management), but they are defined by the best practices that they employ in their drive to meet their performance objectives and create value for the organization.

Source-to-Pay Software Advantages

Source-to-pay automation eliminates rogue spending, decreases supplier risk, improves the procurement process, and saves money. The source-to-pay cycle may be digitally transformed to help businesses increase their ROI and establish a strong supplier network. The following are five significant advantages of digitizing the S2P process:

1. Cost-cutting through synergy

Manual chores can be automated to save time and money. According to Ardent Partners, companies that integrate expenditure analysis into their sourcing operations save between 24 and 41 percent more for every project. Savings leakage may be reduced by up to 38% by closing any sourcing/contracting process gaps.

2. Ensuring that the rules are followed

The automated Source-to-Pay procedure is meant to prevent contract or policy breaches from occurring. Compliance may be ensured by using a guided procurement strategy. Simfoni’s S2P automation system helps users through the requisition process, reducing off-contract spending and directing buyers to the right suppliers, goods, and services.

3. Reduce risk by diversifying.

The pandemic has served as a stark warning to all businesses to establish resilient supply chains and disperse risk across a diverse supply network. S2P automation also aids in the development of a diverse and flexible supplier base. This allows the sourcing team to create even more value by simplifying the supplier base and assuring business continuity.

Having a single source of truth for your supplier base also helps to foster collaboration and visibility. The Simfoni Supplier Network portal unites buyers and sellers on a single platform and organizes all types of data, including contracts, invoices, purchase orders, and other regulatory papers. It lowers manual intervention and frees up resources for strategic tasks.

4. Effortless integration of technologies

A smooth workflow across the source-to-pay lifecycle is possible with an integrated source-to-pay automation system. The data flow is constant and dynamic, and all of the cycle’s modules are interconnected.

Procurement teams will find it extremely simple to fill in data while maintaining information flow. The implementation method for Simfoni advanced S2P automation is quick and easy, providing a seamless process flow.

5. High User Acceptance

The most popular source-to-pay technology systems are those with a huge user base. Only then will the company be able to fully profit from a digital system. A user interface that is not only simple to use but also consistent across different source-to-pay modules is one of the most important factors in increasing user acceptance. Increased user adoption aids in increasing ROI.

Conclusion

Source to Pay can help you make better use of your resources while also empowering your procurement personnel.

On the other hand, Automation may speed up this process and produce concrete benefits in the shape of higher productivity, cost savings, and successful procurement with quick turnaround times. So, for long-term benefit, go with S2P automation.

Frequently Asked Question (FAQ)

What are main differences between S2P and P2P?

- S2P (Source to Pay): Encompasses the entire procurement process, focusing on strategic aspects like supplier relationships and optimization.

- P2P (Procure to Pay): A subset of S2P, it handles transactional aspects, ensuring efficient procurement and accurate, timely payments.

What are the examples of source to pay?

Examples of source to pay activities and components include:

- Strategic Sourcing: Identifying suppliers, negotiating contracts, and selecting vendors based on price, quality, and other criteria.

- Contract Management: Creating and managing contracts, ensuring compliance, and tracking contract performance.

- Supplier Relationship Management (SRM): Collaborating with suppliers to improve performance, reduce risks, and drive innovation.

- Procurement: Executing the purchasing process, which involves requisitioning, ordering, receiving, and managing inventory.

- Invoice Processing: Receiving and validating invoices, matching them to purchase orders and contracts, and processing payments.

- Payment: Making payments to suppliers accurately and in a timely manner, often through accounts payable systems.

What are the steps of source to pay?

The steps of source to pay typically include:

- Sourcing: Identifying sourcing opportunities, conducting market research, and selecting suppliers through negotiations and bids.

- Contracting: Creating and managing contracts, defining terms and conditions, and ensuring legal and regulatory compliance.

- Supplier Management: Collaborating with suppliers to monitor performance, resolve issues, and optimize relationships.

- Procurement: Executing the purchasing process, which involves requisitioning, ordering, receiving, and managing inventory.

- Invoice Processing: Receiving and validating invoices, matching them to purchase orders and contracts, and processing payments.

- Payment: Making payments to suppliers accurately and in a timely manner, often through accounts payable systems.

What is S2C and S2P?

- S2C (Source to Contract): S2C is the initial phase of the procurement process that focuses on identifying sourcing opportunities, selecting suppliers, and negotiating contracts. It involves activities like market analysis, supplier evaluation, and contract negotiation.

- S2P (Source to Pay): S2P encompasses the entire procurement lifecycle, from sourcing and contracting to procurement, invoice processing, and payment. It includes both strategic and operational aspects of procurement.

What is role of S2P?

The role of S2P is to achieve several key objectives:

- Cost Savings: S2P helps organizations identify cost-saving opportunities through strategic sourcing, supplier negotiations, and contract management.

- Efficiency: It improves the efficiency of procurement operations by automating and standardizing processes.

- Supplier Collaboration: S2P fosters collaboration with suppliers to enhance performance, reduce risks, and drive innovation.

- Compliance: It ensures that procurement activities comply with legal and regulatory requirements, as well as internal policies.

- Visibility: S2P provides real-time visibility into procurement activities, spending, and supplier performance, enabling data-driven decision-making.

How can organizations effectively integrate S2P and P2P processes for seamless procurement?

Effective integration of S2P and P2P processes involves aligning strategic and operational procurement activities. To achieve seamless procurement:

- Unified Technology: Invest in procurement software that seamlessly connects both S2P and P2P processes, allowing for data sharing and real-time visibility.

- Cross-Functional Collaboration: Foster collaboration between procurement teams involved in sourcing and purchasing to ensure continuity and alignment.

- Data Integration: Ensure that data flows smoothly between the two processes, enabling insights and decision-making across the procurement spectrum.

- Standardization: Implement standardized processes and workflows to minimize friction during the handover from sourcing to purchasing.

- Performance Metrics: Develop shared KPIs that measure the effectiveness of both S2P and P2P, promoting a unified approach to procurement.

What are the key challenges organizations face when implementing an S2P solution?

Implementing an S2P solution can pose several challenges, including:

- Change Management: Resistance to new processes and technologies among employees.

- Data Quality: Ensuring accurate and consistent data across the S2P system.

- Integration Complexity: Integrating S2P software with existing IT infrastructure.

- Supplier Onboarding: Efficiently onboarding and managing a diverse supplier base.

- Cost and Resource Constraints: Managing the costs and resources required for implementation.

- User Training: Ensuring users are adequately trained to use the S2P solution effectively.

How does technology, such as procurement software, impact the efficiency of S2P processes?

Technology, including procurement software, enhances S2P efficiency by:

- Automation: Streamlining routine tasks like supplier communication, document management, and approvals.

- Data Insights: Providing real-time data analytics for informed decision-making.

- Workflow Optimization: Creating standardized and efficient procurement processes.

- Supplier Collaboration: Facilitating communication and collaboration with suppliers.

- Compliance: Ensuring adherence to procurement policies and regulations.

- Visibility: Offering transparency into procurement activities for better tracking and control.

What are the best practices for supplier selection and evaluation in the S2P process?

Best practices for supplier selection and evaluation in S2P include:

- Strategic Alignment: Align supplier selection with organizational goals and values.

- Supplier Diversity: Consider a diverse supplier base for innovation and risk mitigation.

- Performance Metrics: Define clear KPIs for supplier performance evaluation.

- Regular Reviews: Conduct periodic supplier assessments and performance reviews.

- Risk Mitigation: Assess supplier risks and implement mitigation strategies.

- Collaboration: Foster open communication and collaboration with key suppliers.

How can organizations ensure compliance with procurement regulations and policies in S2P?

To ensure compliance in S2P:

- Policy Alignment: Align S2P processes with procurement policies and relevant regulations.

- Training and Education: Provide training on compliance requirements for procurement teams.

- Audit and Monitoring: Regularly audit and monitor procurement activities for compliance.

- Documentation: Maintain comprehensive records of procurement actions to demonstrate compliance.

- Supplier Compliance: Ensure that suppliers adhere to ethical and regulatory standards.

What role does data analytics play in optimizing S2P processes and decision-making?

Data analytics in S2P:

- Optimizes Sourcing: Helps identify cost-saving opportunities through spend analysis.

- Enhances Supplier Evaluation: Provides insights into supplier performance.

- Improves Forecasting: Enables better demand forecasting and inventory management.

- Risk Management: Identifies and mitigates risks in procurement activities.

- Strategic Insights: Informs strategic decisions by providing actionable insights from data.

How can organizations measure the success and ROI of their S2P initiatives?

Data analytics in S2P:

- Optimizes Sourcing: Helps identify cost-saving opportunities through spend analysis.

- Enhances Supplier Evaluation: Provides insights into supplier performance.

- Improves Forecasting: Enables better demand forecasting and inventory management.

- Risk Management: Identifies and mitigates risks in procurement activities.

- Strategic Insights: Informs strategic decisions by providing actionable insights from data.

What strategies can organizations employ to improve supplier collaboration and relationship management in S2P?

Strategies for supplier collaboration in S2P include:

- Communication: Maintain open and transparent communication channels with suppliers.

- Joint Planning: Collaborate on joint business plans and strategies.

- Performance Reviews: Conduct regular performance reviews with suppliers.

- Innovation: Encourage suppliers to contribute to innovation and process improvement.

- Conflict Resolution: Develop effective mechanisms for resolving conflicts and disputes.

What are the potential risks and mitigation strategies associated with S2P, particularly in terms of contract management?

Potential risks in S2P contract management and mitigation strategies include:

- Contract Non-Compliance: Regularly audit contracts to ensure compliance and implement corrective actions if necessary.

- Supplier Disputes: Establish dispute resolution mechanisms within contracts.

- Data Security: Implement robust data security measures to protect sensitive contract information.

- Vendor Lock-In: Include exit strategies and termination clauses in contracts to mitigate vendor lock-in risks.

How can organizations adapt their S2P processes to address sustainability and ethical considerations in procurement?

To address sustainability and ethics in S2P:

- Supplier Screening: Conduct due diligence on suppliers to ensure they meet sustainability and ethical standards.

- Sustainability Metrics: Implement sustainability metrics and goals in sourcing and procurement.

- Supplier Code of Conduct: Develop and enforce a supplier code of conduct that aligns with ethical standards.

- Transparency: Promote transparency in procurement activities and supply chains to identify ethical issues.

- Continuous Improvement: Regularly review and update S2P processes to incorporate evolving sustainability and ethical considerations.

Useful Resources

- Cost Reduction Strategies in Procurement.

- Effective Procure-to-Pay Process Guide (P2P Procurement).

- Guide to eProcurement software & Solutions.

- Guide to Manage Tail Spend and Improve the Bottom Line.

- Guide to Procurement Software & eProcurement Solution.

- Guide to Understanding Category Management in Procurement.

- Leveraging AI & Machine Learning in Procurement.

- Procurement Analytics & Implementation.

- Procurement Management - Key Steps and Roles.

- Procurement Marketplace - Reinventing Procurement

- Savings Tracking Process in Procurement.

- Source to Pay Process, Steps & Definition.

- Spend Analysis in Procurement: Importance, Process & Examples.

- Supplier Diversity in Procurement

- Sustainable Procurement - Importance & Best Practices

- Understanding the What, Why, & How of Strategic Sourcing.

- Procurement Auctions – How It Works, Example, and Risks.

- Supply Chain Management (SCM): How It Works and Why It Is Important

- What is Contract Management - Everything You Need to Know

- B2B Marketplace - The Ultimate Guide to Procurement Marketplace

- Spend Management - Importance & Best Practices On Business Spend Management Software & Solutions

- Strategic Sourcing – Ultimate Guide To Strategic Sourcing Processes

- Spend Cube – Ultimate Guide to Spend Cube Analysis

- Procurement Software - Automate Your Procurement Process