COST REDUCTION

Comprehensive Guide to Procurement Cost Reduction by Simfoni’s Procurement Professionals

Table of Contents

Introduction to Cost Reduction

Cost reduction in procurement is the process of reducing unnecessary expenses to increase bottom line and increase profit margin. Procurement Cost reduction strategies include vendor consolidation, reducing maverick spend, effective category & tender management and improved risk management.

Simfoni.com Tweet

Now more than ever, cost reduction has become the number one focus for businesses. Even if the pandemic did not affect your bottom line, you must look for opportunities to implement more excellent cost-saving methods.

It’s essential to conduct cost reduction in a way that has instant and lasting effects. One way to do this is to manage your procurement costs. The costs associated with acquiring goods and services from external sources are a key performance indicator that is vital to your organization’s success.

Why? Because procurement costs provide a straightforward and traceable way to measure the performance of the entire procurement process and the business in general.

The few cost reduction essentials every business should know are:

- Cost reduction must involve reducing and not cutting out costs entirely.

- The reduction measures should not affect the processes and product quality.

- The manufacturing process should be changed without affecting product quality or nature.

- Cost reduction should never be a short-term process; rather, it should be more of a long-term solution.

As a business, there are several ways you can implement these cost reduction essentials. But first, it’s vital to understand the different types and components of procurement costs and identify why these expenses occur.

What is Cost Reduction in Procurement?

In terms of procurement, cost reduction reduces unnecessary expenses to increase an organization’s bottom line and profit margin. While the importance of cost reduction concerning other strategic business goals is often debated, there is no denying its significance in procurement.

We often talk about cost reduction in reference to savings made during a purchasing process; however, it is much more than that. For example, developing cost-saving strategies for an organization’s procurement process involves several components such as:

- Re-negotiation and revision of supplier and vendor contract terms and conditions.

- Administrative and operational process improvements.

- Leveraging the use of data and technology.

- Improved risk management.

- Category and tender management.

- Reducing maverick spend.

By implementing cost-efficient strategies, procurement management teams can optimize operational workflows and maximize their profitability.

Cost Reduction vs. Cost Cutting

While these two may be related, they are quite different concepts. Cost-cutting is a strategy put into effect by a company as a last resort; cost reduction, on the other hand, is not associated with necessity.

Unlike cost-cutting, where the company is forced to undergo changes, cost reduction is a voluntary process that enhances productivity and profit. Most of the time, cost-cutting measures tend to be harsh compared to cost reduction.

So reduction is about reducing the increasing costs and involves strategies that uplift the company and helps it grow. On the other hand, cost-cutting is more of a “desperate times leads to desperate measures” strategy and symbolizes instability.

Cost Reduction Strategies

While several cost reduction and cost-cutting strategies may overlap, some cost-cutting techniques do not apply to cost reduction. The following are some standard cost reduction strategies

1. Modifying Sourcing

Organizations can modify sourcing resources and procurement, and this tends to be a time-consuming process. This step can involve switching to cheaper alternatives or sourcing from local produce. Changing sourcing is undertaken to reduce long-term costs. Instead of being dependent on one supplier, the company switches suppliers periodically for cost advantage.

2. Improvising Processes

Many businesses sometimes decide to incorporate expensive processes which can be avoided. Improvising techniques to eliminate costs is one essential strategy of cost reduction. Minor improvements in the manufacturing processes, such as preventing wastes or waste management processes, can help save costs in the long run.

3. Utilizing Energy-Saving Equipment

Businesses utilize a lot of energy which tends to increase costs. Finding energy-saving equipment or using alternative sources of energy saves costs over time. So, for example, some companies can decide to substitute office printers or stationery with cost-saving alternatives like going digital. This will not only save paper but electricity as well.

4. Hiring Processes

The more experienced an individual is, the higher the cost of hiring and maintaining them as an employee. Hiring graduates or interns for specific frontline or baseline positions is much cheaper. The company could then focus on strengthening its training and development processes to train recruits better. This also gives the individuals opportunity and industrial exposure while saving a lot of money on remuneration.

5. Expense Reduction

Another strategy that organizations use to reduce costs is to cut down on expenses. An example could be the use of video conferencing instead of physical travel to bring down travel costs. Another great example is promoting carpooling for the work commute.

6. Product Alternatives

Bringing out product alternatives that appeal to different income segments of the population can be economical in the long run. However, businesses must not compromise on product quality while developing the financial product alternative.

Why is Cost Reduction necessary in Procurement?

There are several advantages and benefits of cost reduction in procurement. These include:

- Profits: From the baseline, cost reduction increases profit margins which is the most sought-after advantage. A company that willingly or unwillingly performs cost reduction to increase the profits will have more money to invest in other areas.

- Productivity: Cost reduction increases productivity at some level since the underperforming employees see that the company policy has changed and more is required.

- Improving standards: Cost reduction helps improve the procurement processes’ standards by directly affecting the nature of the current procurement methods.

All these advantages are essential for successful cost reduction implementation in an organization.

However, while cost reduction does offer some fantastic benefits, there are disadvantages that you should know. Knowing how things can go wrong with cost reduction will help you mitigate the risks associated with the process.

Disadvantages of Cost Reduction:

- Cost reduction can be mistaken for cost-cutting: This can cause alarm throughout the company as employees may think that the company is going through a financial crisis.

- Not all change is good: Sometimes, cost reduction involves changing processes that may be harmful and cause additional losses instead of profits and improvement.

- The initial implementation may be expensive: While the goal of cost reduction is to have long-term cost savings, the initial implementation may be too expensive for some organizations. For example, switching to alternative energy sources may be too costly for some businesses.

- Product quality is compromised: Focusing too much on cost reduction measures can reduce product quality. This, in turn, will affect the long-term vision of the company by lowering the brand value.

Cost reduction is a double-edged sword and should be handled carefully. If done the right way, it will boost profits without affecting the company significantly. However, it could backfire and fail miserably if implemented incorrectly.

How Procurement Cost Works

What are Procurement Costs?

The budget for procurement in inventory-based organizations can make up a substantial portion of their resources.

These elements are all part of the procurement process:

- Purchase Planning

- Specifications Assessment

- Strategic Sourcing (supplier choice and agreements)

- Financing

- Negotiating Payment Term Process

- Contract Management

- Vendor Management

- Inventory Control

Typically the steps in a procurement process are as follows:

- Recognize the need for the product, whether it’s a new order or a re-order.

- The procurement department receives a purchase requisition.

- The department reviews and approves the request and sends it to the accounting department for approval.

- Quotation requests are sent to prospective vendors.

- The company negotiates contracts with the vendor.

- The company receives goods and services from the supplier.

- The orders, slips, and invoices are reviewed.

- Payment to the vendor is processed.

- Records are kept for bookkeeping and auditing

Types of Costs in Procurement

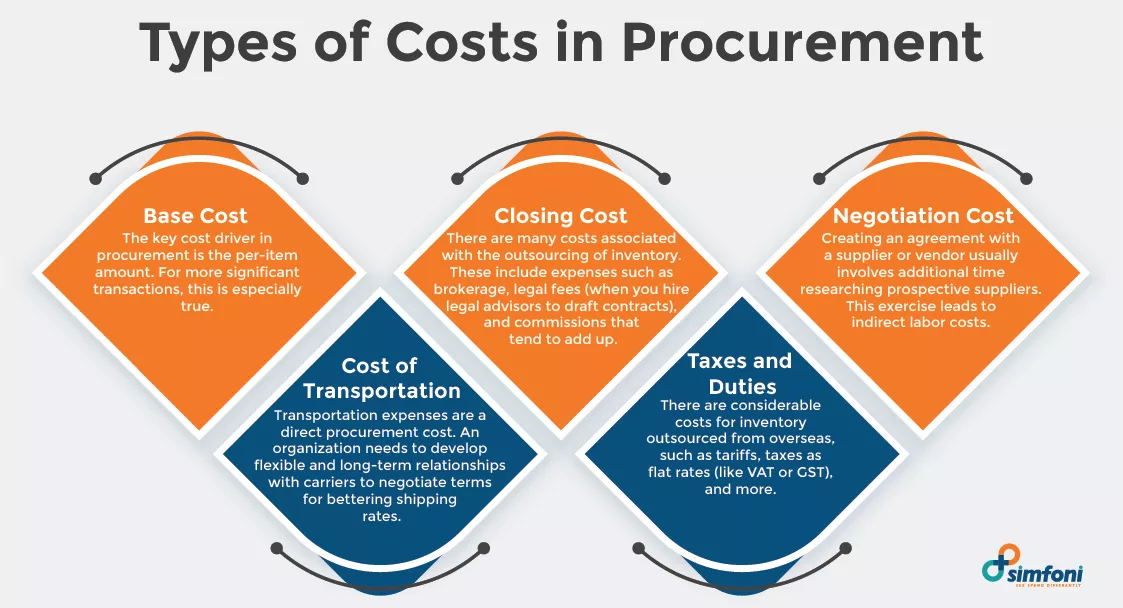

Generally speaking, five different components make up the procurement life cycle. All organizations should consider these elements when accounting for their annual procurement costs. Simply adding up purchasing expenses will not produce an accurate picture of the total cost.

1. Base Cost

The key cost driver in procurement is the per-item amount. For more significant transactions, this is especially true. The per-item amount is the most considerable expense and typically the most challenging to reduce. The best method to reduce this cost is to find competing suppliers with the same products and negotiate the best price per unit.

2. Cost of Transportation

Transportation expenses are a direct procurement cost. An organization needs to develop flexible and long-term relationships with carriers to negotiate terms for bettering shipping rates.

3. Closing Cost

There are many costs associated with the outsourcing of inventory. These include expenses such as brokerage, legal fees (when you hire legal advisors to draft contracts), and commissions that tend to add up.

4. Taxes and Duties

There are considerable costs for inventory outsourced from overseas, such as tariffs, taxes as flat rates (like VAT or GST), and more. Import taxes and duties can be complex, and organizations without the in-house expertise to manage them will have to hire brokers to assist with the customs process.

5. Negotiation Cost

Creating an agreement with a supplier or vendor usually involves additional time researching prospective suppliers. This exercise leads to indirect labor costs. Negotiating with suppliers can also be costly, especially if you have staff that has to travel to make the agreements.

How does effective Procurement Reduce Cost?

So now that we know that cost reduction is essential and has numerous benefits, how does it work with effective procurement planning?

Let’s look at some numbers first. According to an article on Scribd procurement-managed expenditure accounts for an average of 65-75% of many businesses’ outflows.

This is a considerable percentage, and ineffective procurement leads to poor decision making such as emergency procurement that requires fast and expensive transportation. Regardless of the economic situation, effective procurement is good business practice because it reduces unnecessary costs.

Procurement Cost Optimization

Fundamentals of Procurement Cost Savings

Importance of Procurement Cost Savings

Focusing only on procurement cost savings is not a good long-term strategy. The key to success is to improve engagement among all stakeholders. Once this is achieved, savings are inevitable.

Procurement cost savings are the main focus for many businesses for a couple of reasons, the most important being they are:

- Easy to track: This is the easiest and most objective way of measuring procurement performance if done right. So there’s no doubt why this is a popular way to track procurement performance.

- Impact: It directly affects the bottom line compared to other metrics like risk mitigation.

Cost Saving vs. Cost Avoidance

This guide would not be complete unless we talked about the difference between cost avoidance and cost savings. Procurement should be tracking both to understand better the entire value delivered by procurement.

Cost Avoidance

According to the Chartered Institute of Procurement and Supply:

“Cost avoidance is a reduction in cost resulting in a spend that is lower than would otherwise have been if the cost avoidance exercise had not been undertaken.”

So, for example, let’s assume you’re paying an internet provider for a yearly subscription. The vendor sends you a renewal contract that includes a 10% increase. You use your negotiations skills to avoid the 10% increase by signing a long-term renewal contract. This is cost avoidance.

Cost Savings

Cost savings, on the other hand, is more tangible. For example, you could negotiate down the per-unit price of an item so that your sourcing is now cheaper, thus saving you money.

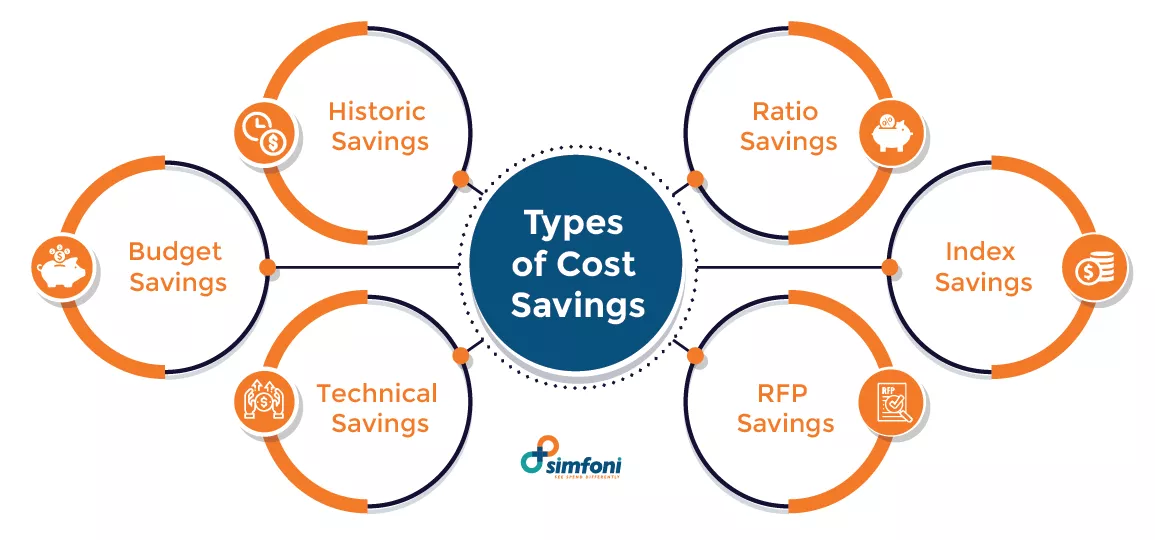

What are the Types of Cost Savings?

Before discussing procurement cost optimization, we need to understand the types of cost savings commonly found in most businesses. These are:

1. Historic Savings

Refer to changes in unit prices as compared to the previous period. Historic savings are calculated based on a baseline of the prior year. So, for example, it could be from a critical indicator like the price average from the year before. Such indicators are then compared with the current price, and the difference is then calculated.

2. Budget Savings

These are derived based on the difference between the actual price (price on the invoice) and the planned budget.

3. Technical Savings

Technical savings are a consequence of changes in the technical specification of a product. For example, when a reasonably priced alternative replaces the requirement for an expensive product – the difference in prices, as a result of this change, is known as a technical saving.

4. RFP Savings

RFP stands for Request for Proposal, and it is categorized as an ‘avoidance’ kind of saving. Why? Because through the request for proposal from various suppliers, the company can choose a supplier from the submissions received. In most cases, the lowest bidder is the one who is selected.

5. Index Savings

These are savings acquired as a result of external market developments which usually affects the prices for material and services.

6. Ratio Savings

These are a combination of savings. So, for instance, it could be a combination of technical and budget savings.

Objectives and Methods of Procurement Cost Reduction, and how can you Leverage Them?

The objective of cost reduction in procurement is to bring down the cost of the entire procurement process. Methods of cost reduction can be applied from identifying suppliers and vendors right through to the manufacturing and delivery of the final goods or services.

The important questions to ask now include:

- What methods can you implement to have a successful cost reduction strategy?

- What are the cost reduction strategies?

- How do you implement a cost reduction strategy?

Using accurate data, working continuously and systematically with your procurement costs is crucial to realize savings and improve profitability. Organizations need to identify cost drivers to implement procurement measures.

Remember that these methods, or levers, can simultaneously affect several cost drivers due to linkages and interrelationships. Depending on how many resources and time an organization has, it can implement several short-term and long-term initiatives. Let’s discuss them in detail below:

Short-term Initiatives and Quick Wins

1. Revisit Current Contract Terms

One of the fastest ways to introduce cost reduction is to challenge the terms of an existing contract. It’s an acceptable practice in procurement to revisit current contract terms. Arrangements that have existed for a long time offer another cost-reduction avenue for organizations.

Any contract not reviewed for over three years is likely to have some pricing that has become uncompetitive and outdated. Economic environments change, consumer consumption patterns shift and technology is advancing at an alarming rate.

Organizations should not be afraid to discuss with suppliers about potential changes to certain processes like purchasing frequency; this can lead to volume discounts. Conducting market research and benchmarking will provide a better forum for pricing changes with your suppliers.

You must learn to negotiate better terms with current suppliers, focusing on lower prices and considering contract extensions to achieve lower costs. Negotiation can be a strategic procurement lever.

2. Challenge Specifications

The next step is to figure out whether you need this product or service? Once that is settled, analyze the extent of the need and further review the specifications or design. Most product packaging and specifications are often based on supplier proposals or set with one particular supplier or brand in mind. Suppose the organization can set requirements based on expected performance or outcome. In that case, this will allow for increased competition by a broader range of suppliers.

3. Reevaluate Necessities

Reevaluating necessities in terms of inventory items or services is essential to ensure that it positively contributes to the business’s profitability in the long run. Procurement management teams should analyze the extent of customer demand for any particular item. This helps them to see if any improvements can be made to reduce production or supplier costs.

Some companies need to adopt standardization to reduce variety. For example, suppose a company is supplying a single brand of vehicles. In that case, spares compatibility will keep inventory storage costs at a minimum compared to the costs for an organization with five brands of cars. Furthermore, economies of scale can be achieved during the sourcing process.

4. Eliminate Maverick Spending

Maverick spending is defined as unauthorized purchasing outside agreed contracts. Sometimes it is also referred to as rogue spending or spend leakage. Maverick spending can account for a large percentage of purchases when there is no centralized purchase-to-pay (P2P) procurement process.

This can be a significant challenge to any cost savings initiative. Why? These purchases are most likely not included in any supplier discounts that may have been established previously.

To avoid this, procurement management should ensure that all purchases are compliant with supplier contracts. Management should also ensure that the orders’ prices are pre-approved by the organization.

Usually, spend analysis will highlight where uncontrolled spending occurs so that control measures such as purchase requisitions, e-catalogs and purchase requisitions can be implemented to reduce maverick spending. Ensure that you go over the process with your team so they know how to handle everything correctly.

5. Challenge Operational Costs

Effective procurement planning helps reduce costs by ensuring the best use of administrative resources—poor planning results in expensive emergency procurement actions and high transport costs. Organizations need to streamline internal P2P processes. Whether automated or not, this can reduce operational and transaction fees and additional and unnecessary documentation.

6. Plan Ahead

Having a proper procurement plan in place allows companies to understand better how to use their resources and time best. This minimizes instances of emergency product purchases, which, can be expensive due to expedited delivery costs

7. Assess Suppliers

Procurement teams should regularly assess their vendors and suppliers to ensure their prices for products and services align with market values. Transparency is essential within supplier relationships so that costs are kept within a competitive range.

We also recommend that procurement management implement an effective supplier management system and minimize the number of vendors. This will help reduce procurement costs and enhance warehouse efficiency.

Assessing suppliers will help you identify whether there are similar vendors in your database that are not competitive.

8. Leverage the Use of Data

Data is crucial to cost reduction in procurement. It is related to sales, purchase orders, customer demand, and supplier performance and can reveal opportunities for further savings. So use the data you have on past purchases and supplier performance to drive re-negotiation efforts. For example, if a particular product is decreasing in popularity among customers, retail and procurement managers can re-negotiate with their suppliers to reduce the wholesale price.

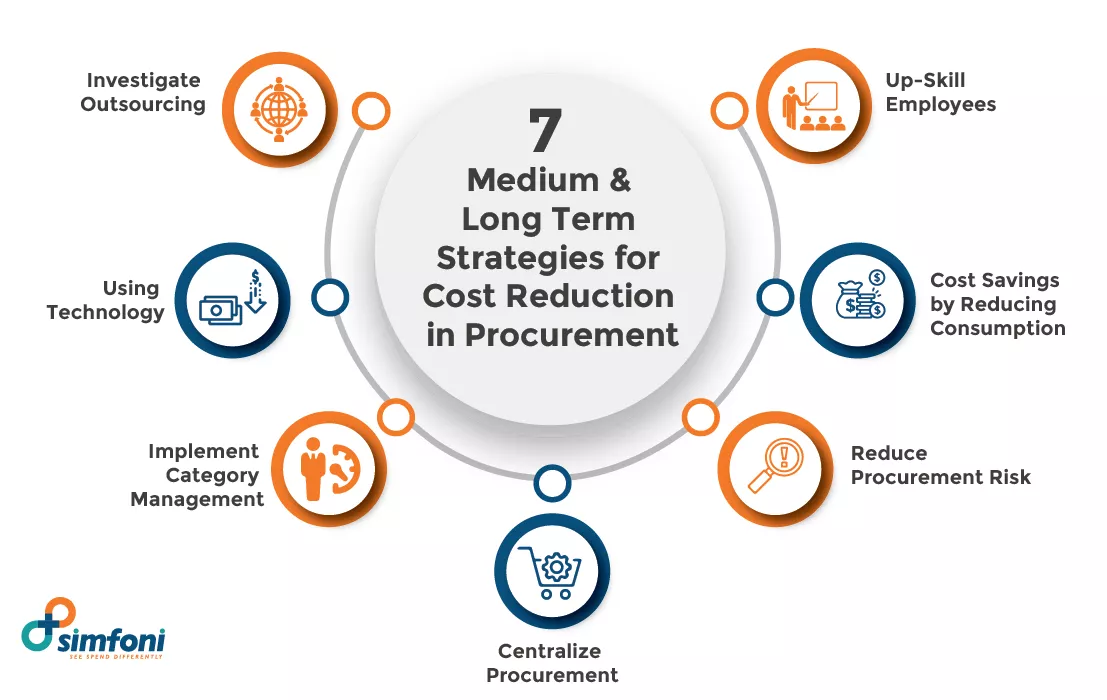

Medium- and Longer-Term Initiatives

Medium and longer-term cost-cutting initiatives are usually implemented for 4 to 10 years. Unlike the quick cost reduction methods we’ve discussed above, the following initiatives are used to steer the company’s future.

1. Investigate Outsourcing

Outsourcing can be defined as a strategy through which non-core procurement activities or functions are handed over to specialist external providers. In simple terms, outsourcing is the practice of procuring services or goods from an external provider such as a foreign supplier.

Depending on the industry and the business, outsourcing can be cost-efficient because it reduces labor and rent expenses. Moreover, outsourcing is especially suited to indirect procurement categories such as security, transportation, facilities management, security, and logistics.

For procurement purposes, the cost reduction benefits include:

- Access to market knowledge and global expertise in categories where there is little to no in-house experience or capacity.

- Lower costs because the outsource partner’s economies of scale combine customers’ requirements.

- Outsourcing low-value/high-volume purchases free up expensive internal resources.

- Time-consuming negotiations and contracting are managed by.

Businesses should ensure that they analyze the cost of insourcing compared to external spend and the cost of outsourcing compared to doing it internally.

2. Using Technology

Technology can find solutions that address all or part of the procurement process, in a way that reduces costs. There is a variety of advanced software for cost reduction in implementing P2P, spend analysis, e-procurement, including RFP management, e-catalogs, and e-auctions.

Additionally, in supplier relationship management (SRM), an online self-service portal streamlines the communication process between buyer and seller. By cutting down on human intervention, businesses can reduce costs.

Let’s discuss real-life examples. Simfoni’s inventory management software is a tool that can simplify inventory counts and track your organization’s expenses over time. This provides visibility into how much waste you are producing and what adjustments to make to prevent it.

In terms of inventory, inventory-specific solutions can have suggested ordering features. It collects sales data, current inventory levels, and supplier delivery schedules to alert businesses when they need to replenish a product. This will further enable organizations to prevent unnecessary spending due to over-ordering.

3. Implement Category Management

For procurement cost reduction, the main objective of category management is to group and manage each type of expenditure comprehensively. Implementing a category management structure through the entire procurement lifecycle requires careful planning.

When category management is in place, it allows procurement teams to use their time wisely and not waste resources on repetitive transactional buying. This way, total spend on a commodity or a service can be leveraged to offer larger volumes or scope to critical suppliers.

A well-defined category-based analysis can bring cost reduction opportunities to the forefront, and procurement managers will be able to negotiate lower rates with suppliers and avoid wasting resources.

4. Centralize Procurement

Key areas of opportunity savings are not visible in a decentralized procurement structure. The likelihood of duplicating purchases and maverick spending is high even if the global procurement organization is center-led.

A centralized procurement strategy allows one department to handle all purchasing decisions. This way, the organization has a unified global sourcing strategy. Having a centralized system can also provide other opportunities for savings, such as reducing the number of staff and training necessary for procurement teams.

Moreover, a rationalized supplier database leads to increased competition among suppliers and reduced supply costs. However, implementing a spend analysis tool globally can also offer many of the same benefits.

5. Reduce Procurement Risk

Every industry comes with risks, and one of the biggest ones any company could face is supplier dependence. While organizations should aim to consolidate suppliers and vendors when possible, one of the key ways to manage risk is to ensure that the procurement process doesn’t depend too much on one supplier.

One way to mitigate this risk is always having a backup supplier available to cover the essential goods and services required to keep operations running smoothly. Furthermore, part of risk management also means focusing on cost avoidance, such as negotiating contracts with value-added services like extended warranties or free shipping to save money.

The role of risk management within procurement is to ensure that correct management controls are in place, especially for emergency or ad-hoc purchases. This means organizations should be paying close attention to contracts, following up with suppliers, and taking action to avoid logistical issues.

6. Cost Savings by Reducing Consumption

The data shows that every dollar you spend on supply management provides a return of $6.77. If organizations decrease demand, they can achieve cost savings. This can be done by reducing overall consumption and taking cost-cutting measures to eliminate hidden costs.

This is a significant factor to consider when you’re buying things like laptops, smartphones, or leasing company cars for staff. It’s important to evaluate whether all business purchases are necessary and establish follow-up of policies/guidelines to minimize over-consumption.

7. Up-Skill Employees

Employees are a company’s best resource. Spending money on training employees to make better decisions can improve your bottom line over time. For example, investing in training to improve negotiation skills can improve supplier relationships and easier contract management.

Overall, reducing expenses and improving cash flow using short, medium, and long-term initiatives should be a goal when implementing cost reduction measures in procurement.

How do you Calculate Cost Savings in Procurement?

Unfortunately, cost savings cannot be measured using one standard formula. Additionally, procurement is not an isolated process but incorporates other disciplines on which it is partially dependent. This makes it complicated to measure and gauge the actual value of cost savings.

In procurement, cost savings are always viewed as a negative change from previous costs compared to the new negotiated price. Without a prior cost reference, cost savings could be calculated from the first offer received or market-related benchmarks.

So how do you calculate cost savings in procurement? Experts use the average price of all received quotes and subtract it from the negotiated contract price. This value is then multiplied by the actual number of items bought in a certain period.

How to Optimize Procurement Costs

Even if your business is not suffering a financial crisis, it is always essential to find cost-saving opportunities. This approach will offer the organization leverage when negotiating with suppliers to gain reductions in return.

It’s recommended to work with existing suppliers in creating real and lasting cost reductions because you’ve already vetted their capabilities concerning what you require.

If you were to follow the traditional cost savings route, the process would likely involve you making a tender, negotiating, selecting a new supplier, implementing, and then maybe realizing cost savings. The challenge with this approach is that it takes time and significant resources to do this. This time lag on cost-saving is not a desirable outcome.

Cost optimization initiatives aim at getting the best value for spending. However, any significant changes in cost structure require big changes. Procurement’s role is not limited to negotiating the best pricing and terms for all your purchases. For proper optimization, sourcing, procurement, and vendor management teams need to take it further.

What we are presenting today instead are concrete suggestions on how companies can reduce costs effectively using initiatives aimed towards existing suppliers without running any tenders or RFQ processes.

Steps to Optimize Procurement Costs:

1. Remove Unnecessary Costs

Analyze and figure out which costs you don’t need. In more prominent organizations, there is sometimes a lack of transparency between departments. The individuals who approve and pay for products and services (external costs) and those who use and utilize the associated product or service are not in communication. Communication is a key ingredient in cost optimization.

Moreover, it’s imperative to identify the products and services that are not in use. This can be achieved in different ways.

For example:

- IT spend: it’s essential to identify the specific services or modules that are not being used. The best way to achieve this is by making a list of all the IT solutions purchased by your company.

- Direct spend: Identify and measure your stock turnover rate, split down per supplier and product. Rank all suppliers and products according to stock turn. For suppliers and products with the lowest stock turnover, you may need to analyze the answers to the following questions:

- Can the business function efficiently if you cut off this product or supplier?

- Are you able to stop buying this product or from this supplier?

This will help you make a decision on whether to keep the product or supplier.

2. Offer your top suppliers help in return for agreeing to your cost-saving initiatives

By focusing on your top suppliers, you can probably cover over 60% of your total spend and, therefore, a large share of your total cost reduction potential.

Meet with your top suppliers online for a business review meeting to discuss potential cost reduction initiatives. It’s vital that you make it clear to your suppliers that you intend on bringing something to the table and offer help in any way you can, aside from cost increases of course.

3. Reduce Non-Conformance Costs

These types of costs arise when suppliers are not delivering in accordance with the expected quality, quantity, or time. To reduce these costs, organizations cab start tracking any supplier non-conformance experience. Talk to the people in your company receiving and using the goods or services delivered by your suppliers. You should get a clearer picture.

Best Practices for Procurement Cost Reduction & Procurement Savings

Implementing procurement best practices for cost reduction and savings will help ensure that vendor management decisions, sourcing, and procurement, create maximum value for your organization.

So let’s look at the fundamental best practices you should be aware of:

- Create a primary cost optimization team: All procurement elements such as sourcing, procurement, and vendor management should be represented on a cross-functional team, including operational and business leaders. This encourages the exchange of skills and knowledge.

- Become a trusted authority in the marketplace. Organizations need to research and monitor markets to provide stakeholders with accurate market intelligence on developments and trends. This could include information on new service delivery options, disruptive competitors, or emerging business opportunities.

- Work within the organizational framework.

- Develop a flexible sourcing approach. For example, contract negotiations for certain core products will be expected to remain in place for ten years, while some short-term products might only have six-month supplier contracts.

- Share credit where it’s due. It’s essential to recognize market leaders who contribute to sustainable reduction in budgeted spending based on your team’s sourcing insights and market intelligence.

Conclusion

How does Simfoni's Spend Intelligence Help in Cost Reduction & Savings?

At Simfoni, we understand the role that technology plays in digitally transforming procurement processes for businesses. Our software can:

- Capture information, analyze data for insights and automate processes. The increase in cross-system flow improves workers’ ability to make data-driven decisions.

- Help you gain level 4+ visibility on your spending patterns with automated categorization.

- Help users can run their own RFx within the company guidelines using already approved vendors. This captures formerly maverick spend, keeps buying compliant, and reduces the workload of the procurement team.

- Flip Requisitions to start an RFQ process that automates the manual work of emailing vendors, collecting responses, and ranking proposals.

- Gain insights on your procurement efficiency from your existing contracts. Investigate common terms, what is under, and not under contract, and the possible risk of non-compliance.

Additionally, our AI-powered Spend Intelligence solutions can quickly distill and organize your complex spend data to help you discover opportunities and savings. We offer real-time visibility across all categories, as well as insight to identify new opportunities and hidden savings,

Moreover, suppose you want to manage procurement cost reduction and savings effectively. In that case, our spend automation enables businesses to cut costs and puts you in control of the core and non-core spend. With autonomous buying, vendor engagement, invoice automation, and advanced analytics, you get to compose your perfect solution.

Frequently Asked Question (FAQ)

For your help, we have created a list of answers to assist you more.

What is cost reduction with example?

Cost reduction refers to the process of identifying and implementing measures to decrease expenses incurred by a business without compromising the quality or effectiveness of its products or services.

Example: Imagine a manufacturing company that discovers potential to lower its energy expenses by upgrading its machinery to more energy efficient models.

What are the techniques for reducing cost?

Several techniques can be employed to reduce costs effectively:

Process Optimization:

Identify and streamline inefficient processes to reduce resource and time wastage.

Supplier Negotiation:

Negotiate with suppliers for better terms, discounts, or bulk purchase agreements.

Technology Adoption:

Invest in technologies that automate tasks, enhance efficiency, and reduce labor costs.

Lean Manufacturing:

Implement lean principles to minimize waste in production and operations.

Energy Efficiency:

Improve energy management and adopt energy-efficient practices to reduce utility costs.

Outsourcing:

Consider outsourcing non-core functions to specialized providers to reduce in-house overhead.

What is the benefit of reducing costs?

Reducing costs offers several benefits to businesses, including:

- Increased Profitability: Lower costs directly contribute to higher profits.

- Competitive Advantage: Cost-efficient businesses can offer competitive pricing.

- Resource Allocation: Funds saved can be reinvested in growth or innovation.

- Financial Stability: Reducing costs helps maintain financial stability.

- Improved Sustainability: Lower resource consumption contributes to environmental sustainability.

- Enhanced Cash Flow: Reduced expenses result in healthier cash flow.

What is a cost reduction product?

A cost reduction product is an item, material, or component that is chosen or engineered specifically to lower production or operational costs without compromising quality. These products are designed to contribute to overall cost reduction strategies often through lower material costs, improved efficiency or extended product lifecycles.

What is the goal of cost reduction?

The primary goal of cost reduction is to improve overall financial health and sustainability of a business. This is achieved by lowering expenses while maintaining or improving the quality of products or services. Cost reduction aims to increase profitability, enhance competitiveness, and optimize resource allocation.

Is cost reduction a strategy?

Cost reduction can be a strategic approach within an organization. It involves the systematic planning, implementation, and management of activities aimed at reducing costs across various aspects of the business. Cost reduction strategies are integral to achieving financial goals and maintaining competitiveness in the marketplace.

What is quality cost reduction?

Quality cost reduction refers to efforts to decrease expenses associated with ensuring and maintaining the quality of products or services. It involves identifying and addressing issues that contribute to higher quality-related costs such as rework, warranty claims and customer complaints. By reducing quality-related expenses, businesses can achieve better product quality while saving money.

What role does cost reduction play in financial management?

Cost reduction plays a crucial role in financial management by contributing to financial health and sustainability of an organization. It allows businesses to allocate resources efficiently, improve profitability and maintain financial stability. Effective cost reduction strategies are essential for achieving financial goals and optimizing budgetary allocations.

What are the potential challenges in implementing cost reduction measures?

Implementing cost reduction measures can present challenges such as:

- Employee Resistance: Employees may resist changes that impact their work routines.

- Quality Concerns: Reducing costs without compromising product or service quality can be challenging.

- Initial Costs: Some cost reduction measures may require initial investments.

- Market Dynamics: External factors like market competition and economic conditions can affect cost reduction efforts.

- Sustainability: Balancing cost reduction with sustainability goals can be complex.

How can businesses ensure that cost reduction efforts do not compromise quality?

Maintaining quality while reducing costs requires a strategic approach:

- Continuous Improvement: Implement a culture of continuous improvement to identify quality-related issues and address them proactively.

- Quality Metrics: Establish quality metrics to monitor and measure product or service quality.

- Supplier Relationships: Collaborate closely with suppliers to ensure quality materials and components.

- Employee Training: Provide training to employees to maintain quality standards during cost reduction efforts.

- Customer Feedback: Gather customer feedback to identify quality concerns and address them promptly.

Can cost reduction strategies contribute to sustainability efforts?

Yes, cost reduction strategies can align with sustainability efforts in several ways:

- Resource Efficiency: Reducing resource consumption, such as energy and materials, contributes to environmental sustainability.

- Waste Reduction: Minimizing waste and optimizing processes reduces environmental impact.

- Product Lifespan: Extending product lifespans through quality cost reduction can reduce disposal and promote sustainability.

- Supplier Sustainability: Collaborating with sustainable suppliers aligns cost reduction with ethical and environmental goals.

How can small businesses implement effective cost reduction measures?

Small businesses can implement cost reduction measures by:

- Budget Review: Analyze current expenditures to identify cost-saving opportunities.

- Efficiency Improvements: Streamline processes and eliminate redundant tasks.

- Technology Adoption: Invest in cost-effective technologies that enhance efficiency.

- Supplier Negotiation: Negotiate with suppliers for better terms and discounts.

- Energy Conservation: Implement energy-efficient practices to reduce utility costs.

What is the role of leadership in driving successful cost reduction initiatives?

Effective leadership is essential for successful cost reduction initiatives:

- Setting Goals: Leaders define clear cost reduction goals and communicate them to the organization.

- Culture Building: Leaders create a culture of cost-consciousness and continuous improvement.

- Resource Allocation: They allocate resources and support for cost reduction projects.

- Monitoring Progress: Leaders track progress, provide guidance, and make data-driven decisions.

- Employee Engagement: Engaging employees in cost reduction efforts through communication and incentives.

How can businesses measure the ROI of cost reduction initiatives?

Measuring the return on investment (ROI) of cost reduction initiatives involves:

- Defining Metrics: Establish key performance indicators (KPIs) related to cost reduction goals.

- Data Collection: Gather data on cost reductions and related expenses.

- Calculation: Calculate the ROI using the formula: ROI = (Cost Savings / Cost of Implementation) x 100.

- Periodic Evaluation: Continuously assess the ROI to ensure cost reduction efforts remain effective.

How does global supply chain management impact cost reduction strategies?

Global supply chain management can both facilitate and challenge cost reduction efforts:

- Access to Resources: Global supply chains offer access to cost-effective resources.

- Complexity: Managing international supply chains can be complex, requiring additional cost management efforts.

- Risk Management: It introduces risks related to currency exchange rates, geopolitical factors, and supply chain disruptions.

- Sourcing Strategies: Global supply chains may require different sourcing strategies to optimize cost reductions effectively.

Useful Resources

- Cost Reduction Strategies in Procurement.

- Effective Procure-to-Pay Process Guide (P2P Procurement).

- Guide to eProcurement software & Solutions.

- Guide to Manage Tail Spend and Improve the Bottom Line.

- Guide to Procurement Software & eProcurement Solution.

- Guide to Understanding Category Management in Procurement.

- Leveraging AI & Machine Learning in Procurement.

- Procurement Analytics & Implementation.

- Procurement Management - Key Steps and Roles.

- Procurement Marketplace - Reinventing Procurement

- Savings Tracking Process in Procurement.

- Source to Pay Process, Steps & Definition.

- Spend Analysis in Procurement: Importance, Process & Examples.

- Supplier Diversity in Procurement

- Sustainable Procurement - Importance & Best Practices

- Understanding the What, Why, & How of Strategic Sourcing.

- Procurement Auctions – How It Works, Example, and Risks.

- Supply Chain Management (SCM): How It Works and Why It Is Important

- What is Contract Management - Everything You Need to Know

- B2B Marketplace - The Ultimate Guide to Procurement Marketplace

- Spend Management - Importance & Best Practices On Business Spend Management Software & Solutions

- Strategic Sourcing – Ultimate Guide To Strategic Sourcing Processes

- Spend Cube – Ultimate Guide to Spend Cube Analysis

- Procurement Software - Automate Your Procurement Process