Table of Contents

Introduction to Strategic Sourcing

Strategic sourcing is a comprehensive process that enables organizations to maximize their purchasing power and create efficiencies across all spend categories. By analyzing the organization's current supply chain, strategic sourcing allows for improved supplier selection that minimizes risks associated with suppliers while providing visibility into pricing and forecasting. Strategic sourcing also ensures alignment between an organization's business requirements and its supplier base in order to optimize performance, cost savings, quality assurance, delivery timeframes, compliance standards etc.

Simfoni.com Tweet

The analysis of the total cost of ownership (TCO) in direct reference to the existing market trends is based on strategic Sourcing. The system’s primary purpose is to optimize the process of analyzing TCO by developing long-term engagement with the business suppliers which itself is a rigorous process that requires a lot of effort.

Mainly three essential components determine strategic Sourcing.

- Business Spending Profile

- Market Conditions

- Supplier Base

Meeting the business goals is the priority of strategic Sourcing as it aligns everything from the start, such as the vision, to the implementation of every strategy. Strategic Sourcing helps businesses analyze the category of their purchases and the cost and volume of purchases. Therefore, it deeply engages with companies and businesses in order to enhance their overall performance so they can have maximum benefit.

Strategic Sourcing: Definition, Process & Benefits

As the term indicates, strategic Sourcing is a rigorous process that develops expertise across all categories. It reduces the risks connected with the products’ supply, selection, pricing, and even profit forecasting.

Benefits of Strategic Sourcing

The cost-effective and highly productive procedure of strategic Sourcing also indicates more streamlined business operations. However, there is an extended list of advantages of strategic Sourcing as described below that show that it is not a one benefit and all process. It comes up with a lot of advantageous elements that businesses need to discover.

1. Upgraded Cost Saving

A distinct conventionally formed sourcing strategy saves the financial assets of the enterprise in numerous ways. Foremost is the opportunity it provides to the user to choose suppliers that present the utmost value of the products. Then, it also creates enough safe space for the buyer to negotiate and decrease the unit’s price in contrast with the purchases that carry high cost and volume. Finally, external factors are also involved in procurement, so the existing conditions of the market and the maximum profits provide a competitive advantage to the user.

2. Moderation and Minimization of Risk

The cost-targeted approach of strategic Sourcing consists of minimum risks that can arise at any time during the process. Such a system analyzes the overall spending and value as delivered directly by the suppliers, so the enterprises can conduct a thorough assessment that ensures good quality and financial benefit. Supply of the products, services, and customer support are also analyzed and assessed. Therefore, a strategy is divided upon final investigation to reduce and moderate the potential risks. It is the way to closely examine supplier and receiver relations and inform about any disruptions that can arise in the supply chain.

3. Enhanced Adjustment of Business Goals and Operations

The necessary element for maximum benefit is aligning the sourcing activities with the objectives of the business. Strategic Sourcing, therefore, keeps revolving around the goals and operations of the business to create an alignment with them. Thus, the organizations subsequently enhance the performance standard, leading to significant efficiency for the companies and resulting in a minimum number of risks.

4. Space for Extended Advancement

Not leaving to be an isolated activity, strategic Sourcing pays attention to another procedure of evaluation and assessment of the processes that ensure continuous development. This proves to be relentlessly a cycle in which enterprise improves, increasing its chances of sustainability as the business managers build further systems for fixing the flaws. Moreover, the stakeholders receive an opportunity to make good decisions for the long-term improvement of the overall model of the business for expanding the opportunities to capitalize on the services and products while keeping enterprises in a state of competition.

5. Identification and Expansion of the Potential Suppliers

Strategic resourcing pays a keen interest in the cost of procurement. Still, it also gives importance to analyzing the core competencies of the supplies and creating profiles that help the enterprise to consider the supplier’s potential enough to meet some complex requirements. In such a way, the highest value of the suppliers is identified, and they expand in a private system that proves advantageous for the businesses as the companies flourish while in the streamline of keeping the entire system accountable.

6. Better and Transparent Relationships with Suppliers

The organizations, through strategic resourcing, highlight and pay attention to building good relationships with the suppliers. In such a way, they actively engage suppliers in all the crucial decisions to make them experience value. Therefore, the suppliers get enough encouragement to deliver the products and services according to the goals and objectives set by the business. It shows that through different methods of communication and collaboration through technology, businesses are able to create better relationships with the customers.

Importance of Strategic Sourcing

The process of strategic resourcing carries significant importance as it helps identify the overall profile of spending by an enterprise and its potential supplier; therefore, the businesses align with the suppliers better by knowing the requirements of running services.

4.1 Here it is necessary to know that strategic sourcing helps the companies analyze their goals that results in maximum efficiency and minimum risk in the field of the supply chain. Therefore, it’s not only the initial level of product analysis; it is aligning the company’s goals with the supplier to help achieve them and create the highest value and lowest cost.

4.2 Another essential element of strategic resourcing is its relationship with the supplier. It is not based on the short term but carries long-term connection, which mainly consists of the capabilities and compatibilities of the supplier with the enterprise’s goals. The transaction method is also efficient and transparent and depends on choosing different but right components in the duration they are mainly expected. Therefore, the tendency to identify risks increases and the enterprise easily cope with unexpected challenges, such as component shortages.

How to Implement Strategic Sourcing?

Searching for a suitable and potential supplier in strategic Sourcing is a rigorous six-step process. However, the company can see tremendous results after adopting and following the six-step procedure.

Commitment by stakeholder

The process starts with analyzing the core needs of the company or business and the past spending by the company. The company has to be vigilant in allowing the process by providing the historical accounts of all its expenditures to the experts who can plan a project based on market analysis and the company’s data. It outlines the scope of the project and then evaluates the risks connected with it.

Supplier Engagement (RFx)

The next step is to see the vendors in the market and form a contact list of the company’s suppliers. Further, the company sends the request for information (RFI) and approaches the request for proposal (RFP). With all the information provided, it also accesses the requests for quotation (RFQ) wherever possible.

Specification of Evaluation Criteria

You must see the evaluation criteria and develop the supplier’s scorecard accordingly. For it, it is essential to ensure that the supplier has comprehended all the requirements regarding the targets the company tends to achieve. It also means that you need to ensure to keep the evaluation criteria up to mark to set a standard as it can help boost the company’s profile.

Highly Preferable Bidding Process

Now it is also essential to see and remove all the list of suppliers who do not fall on the criteria of meeting the company’s goals. This is also called consolidating the supplier list. Afterward, you need to invite bids from all the rest of the shortlisted suppliers to conduct a competitive process where you can start bidding. You can ask questions for interviewing the supplier to negotiate the terms and conditions you have set.

Supplier Selection

The next step is selecting the suppliers and informing them about your needs, for which you have to take them through another complex official process. This procedure includes completing the due diligence evaluation score report, cards for reference checks, overall risk assessment of financial matters, reputational and operational aspects, and privacy matters.

Implementation of Relationship

Contracting or implementing a relationship with suppliers has to start with formalizing the agreement through written and verbal documents. The company can involve the legal department in conducting such a task to discuss NDA, outline KPIs and engage suppliers in the reporting process. Furthermore, it is necessary to review and rework the reports to see what targets and values have been achieved per the contract.

E-Auction and other digital contract management systems or e-sourcing can augment the steps mentioned above. Such tools can ensure a more authentic report of every activity being done on the platform of the strategic sourcing process.

Strategic Sourcing Methodologies

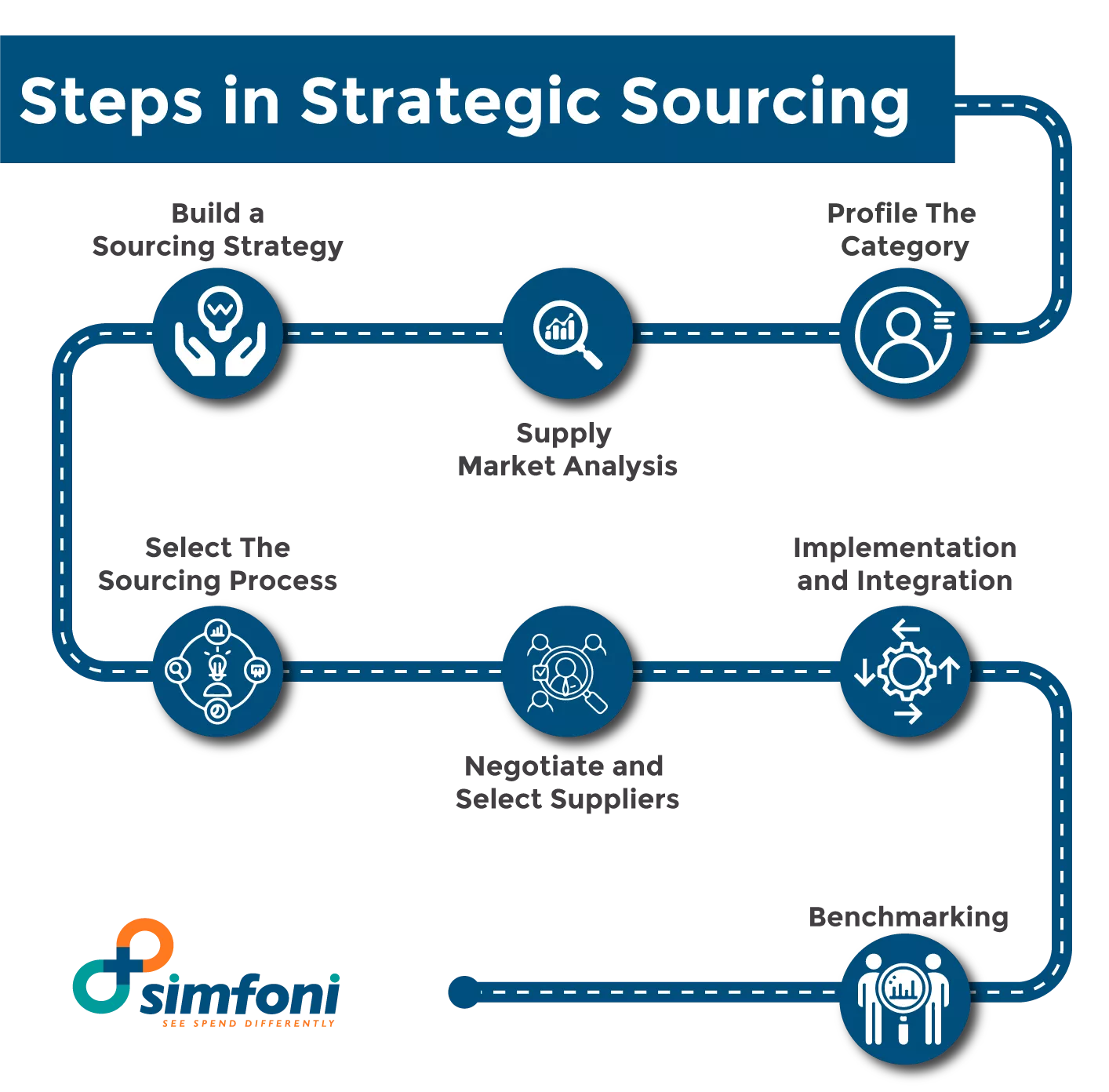

The team assigned for strategic Sourcing works on a 6 step methodology for aligning the business requirements with the supply base. It results in contracts that offer high value to the business. Following are the six steps that include a thorough approach to success.

- Explain the requirements of the company or business

- From the leading team for sourcing project

- Gather and analyze the data for sourcing project

- Development and approval of sourcing plan

- Management and execution of the sourcing contract

- Control of the relationship with the supplier

Use of eSourcing Software in Strategic Sourcing

Procurement nowadays is leading with the integration of automation in the system. Not surprisingly, different organizations are also on the path of adaptation of eSourcing for streamlining all of the activities of strategic Sourcing and simplifying the complexities around them. eSourcing, therefore, targets the selection of suitable suppliers for fulfilling the need of exact Sourcing; it further provides opportunities to different units of business in the organization to cooperate for the activities of Sourcing. It is a diverse task in which each department has unique requirements for the end users to source suppliers that match the critical procurement and compliance rules. eSourcing helps the end user access the competitive pricing of products and services from the list of suppliers and choose the right one.

Factors that drive eSourcing

Upgraded reporting of data and high visibility of sourcing project

The main benefit of eSourcing is to analyze the spending activities of any company, the performance of suppliers, and the evaluation of risk connected with the supply chain; moreover, it generates data that can be useful. Therefore, the overall visibility of performance and assessment of business activities increases, enabling the companies to be more decisive about the different decisions.

Potent management of categories of fundamental spend

Another vital aspect of eSourcing is identifying and categorizing different spending activities in any company’s units. It helps improve the visibility of the various financial types and allows the company to control the spending over the activities.

Risk assessment of the company’s supply chain

Identification, evaluation, and reduction in the risks of a company can be made effective through eSourcing, which keeps every piece of information transparent. It hampers the dangers connected with the company’s supply chain and then improves its compliance. It accelerates the performance of the business and lowers the higher level of spending, mainly caused by the failures of the supply chain. It also creates more efficiency in the company and builds the capacity to deal with external and international disruptions generally occurring in companies.

Advance accountability of projects

The success factor of eSourcing is not the process only, but the phases of accountability in which the performance of sourcing activities is displayed with evidence of the performance of corresponding stakeholders. Therefore, stakeholders’ compliance on a transparent level no longer remains an issue as the sourcing plan targets profit and clear communication.

Used when the primary purpose is to purchase goods and services at the lowest possible cost.

Why Strategic Sourcing?

Supply chain managers mainly try to lower the costs of the company’s goods and services while improving the quality of commodities at the same time. For achieving these goals, strategic Sourcing is a complete procurement management plan that assists the managers in accomplishing the business goals as mentioned above.

1. Classify Suppliers

The first task of effective procurement managers is locating the purest and highest quality of materials at a favorable price from dependable suppliers. It is necessary to classify suppliers while tracking the logistical consideration. One can identify and define suppliers who can work as substitutes in different seasons for one another, as one can prove beneficial in one season and the other in another. It means that classification helps identify a company’s personal needs and the right supplier that can work according to external conditions. Therefore, a consistent flow of services and commodities takes place annually depending on any external factors that can affect the performance of any supplier.

The opportunity for competitive differentiation is another essential forethought for classifying suppliers. Through strategic Sourcing, you can use a particular supplier with a favorable position and brand image. That specific service provider can help you achieve product differentiation, helping the consumer consume your product and service over others. ‘Intel Inside’ and ‘With 100 % Sun-Maid California Raisins’ are some examples for maintaining efficient supply chains in all the different divisions and business partners.

2. Cultivate better relationship

Fundamentally, the best suppliers are the asset with which a company can cultivate positive relationships for the long term. The win-win scenario is only possible through authentic communication so the sourcing professionals can establish the meeting cost, overall seed-to-market, and the turrets connected with the quality. The relationship between the company and supplier helps them deliver quality materials by determining buyer specifications.

In the current era, consumers are fully aware of the ethical practices of business, and therefore they demand the same from companies. There is no doubt that essential hiding information from consumers never works as they can easily hint the fraud-based or lower quality-based services in such a world where every company and brand is competing. For this reason, it is essential to find a more consumer-friendly supplier and competent enough to create and cultivate the same relationship with the user. The company’s relationship impacts the performance and image of products and services and builds other communication channels through effective marketing with the end users. Starbucks’ sustainable coffee is a true example of an enterprise that runs on strategic Sourcing.

3. Boost skills regularly

Maximizing the current strategic sourcing capabilities and skills helps expand the professionals’ Knowledge. It also results in a practical experiment aligning with the modern world, where trends keep changing. Therefore, being up-to-date, skilled, and informative can help managers to build their effectiveness to achieve business goals. It enables the companies to plan and executes the strategy that increases the competence of supply chain infrastructure and lowers the overall cost. The corporate image improves and the tendency to increase sales also gets higher; the market share expands and the company can see a drastic change in the reduction of costs.

4. Follow and accept possibilities.

Continuous Knowledge of a variety of professional skills and competencies is necessary to ace strategic Sourcing of the company as it all depends on making decisions in different stages. It helps to describe, recognize, and assess the main issues in the company. Therefore, it builds principles and creates opportunities and strategies that can create a competitive advantage for the company. It helps the company see all the internal or external challenges; they are essential to consider if they affect the sourcing strategy. It also defines and describes the different problems in global Sourcing and extension of enterprise. It builds channels for negotiation between partners and creates an ethical system. Through strategic Sourcing, the professional works on a framework that target decision-making and problem-solving to see what best can work to pertain to the best approach.

The supply chain process in the global marketplace has expanded, and companies are now adopting a holistic way of taking the business to a higher level. Therefore, strategic Sourcing is helping professionals gain more potential and attain a higher profit.

Strategic Sourcing is the most effective way that facilitates managers and procurement professionals to maximize the effectiveness of the entire business while reducing cost. Therefore, to excel in the competitive world, companies need to use strategic Sourcing that can benefit the industry because of its cutting-edge tools. It can positively impact the business by affecting the supply chain of all kinds and sizes of companies.

Traditional Procurement vs. Strategic Sourcing

The main difference between traditional procurement and strategic Sourcing is the control over the costs for improving the profits of an enterprise. However, it is different from strategic resourcing as the existing way to identify and build relations with the supplier has transformed over the last 10-15 years. In historic procurement, vendors’ selection mainly consisted of the local connections and referrals of peers.

Nevertheless, as technology has advanced, this is the latest global network that has equipped enterprises to work efficiently. In the past, the system created complete visibility of the broad range of suppliers. The procurement workers, therefore, paid attention to cost control by looking for vendors and presenting a chart of the lowest price. Strategic Sourcing depends on a completely different system that recognizes the enterprise and accounts for external factors that are not connected with the cost of the products.

Strategic Sourcing Examples

The accomplishment of business goals in strategic Sourcing makes it one of the most demanding. Following are the examples in which it assists businesses in accomplishing targets.

- Administer the logistics and other conditions in the company’s environment by sourcing the available goods in the exact location. It also includes access to convenient transport.

- High-level differentiation of marketing strategies for the company’s growth is handled healthily. It also analyzes the brand image through the Intel Inside logo, which helps the company correct any existing errors.

- Focus on meeting the guidelines that abide by the company’s compliance by selecting only certified components.

- Complete the source of the sustainable business model by selecting Fair Trade and the manufactured goods in the sustainability cycle.

- Diversification, potential suppliers’ present location, and geopolitical instability reduction. It helps in building emergency plans in volatile areas.

- Reduces the risks connected with the business as it images with the secondary suppliers and monitors the different changes required in the industry. These changes can be made in the field of availability of the product, its quality, overall shipping, annual or regular taxes, current exchange rate, and the required regulations.

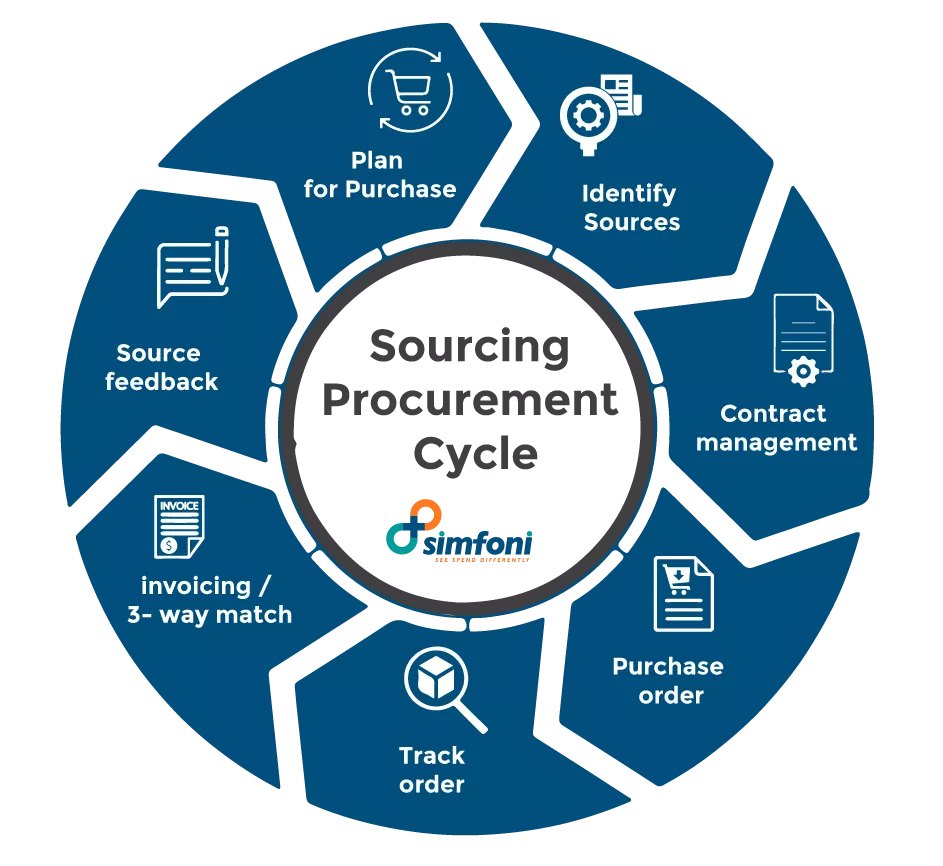

Strategic Sourcing Process

In the market, small and large-sized procurement organizations exist. For the mature category of organizations, strategic Sourcing offers a more comprehensive management plan for their betterment and system. Similarly, depending on the need, the critical commodities in mid-sized enterprises are dealt with differently. Such entities possess maximum value, which carries the potential of an extensive partnership with the supplier and development for the company. The overall experience displays that seven steps based procedure of strategic processing has been highly beneficial and can be further developed globally as there are several benefits of adopting this procedure, such as we can see in the simple application of a company’s software solution. However, some prerequisites, such as clear and direct support and commitment by the organization’s employees and top management, are necessary for following the steps. It is also essential to have objectives that the capable procurement parties and stakeholders must consider for the company’s growth.

Following are the essential steps for achieving the best results

1. Understand Different Categories

Define the commodity by identifying the existing qualities and services efficiently sourced by focusing on their types and sizes. It is equally necessary to locate the end-users, their location, logistics, and the people involved in the supply chain. The visibility of the company’s spending and understanding of the overall category of the commodities can help handle the rest of the projects well. The actual data has to be dealt with for storing, cleaning, analyzing, and validating it.

2. Knowledge about the Supply Market

Investigate the different elements of the cost called cost drivers that construct the product and the service offered by the company. First, analyze all the details, such as the price of the raw material, labor, and transportation, and then evaluate the proposed bids of these elements. Analyze the external marketplace for finding new global and country-wise suppliers and the risks and opportunities connected with them. See the alternatives that can replace the current suppliers to bridge the profit gap.

3. Establish a Sourcing Strategy

The true challenge in the entire procedure is to select the place to buy products and services with minimum risk and cost, even from the current supplier or any prospects in the list. Therefore, choosing the supplier by determining the existing requirements that match the company’s capabilities and comprehensive resources is necessary. For such a task, a team trained to handle cross-functioning projects is more appreciated apart from all the experts in product subject matter and service end users.

4. Choose a proper Sourcing Process

For the prequalification of suppliers, a request for Proposal or Request for Information is the primary method used by strategic Sourcing to solicit bids. Hence, for a good start, RFP should define the specification, which should have information about the delivery of services and the requirement of the services. It should also include the terms and conditions based on an authentic legal system and all the rest of the requirements. Here the company can decide the internal evaluation criteria and the cloud-based software solution that it can use for facilitating and speeding up Sourcing. Cloud-based software offers a more transparent and protective process that is genuinely beneficial.

5. Choose a Potential Supplier and Negotiate Conditions.

Negotiation is necessary for selecting suppliers, and the final selection should follow pre-designed criteria. For such a case, the company must take a vital step by designing a well-drafted contract and signing it in the presence of the supplier. A software solution can be highly efficient and easy to access through all the steps that ensure success and transparency.

6. Implement and Assimilate the Process

The company has to ensure that the involvement of all the key stakeholders is achieved thoroughly. For such a scenario, it has to bring the internal and the product end-users on the same platform for implementing the solution to the problem. Therefore, create a chain of extensive communication with everyone and an authentic focus on change management.

7. Report and Track the Results

Reporting and tracking results are necessary to establish long-term success, as you can quickly identify the supplier’s contribution. Such an example is tracking whether the supplier is adding value at any place or time. For proper feedback, you can use automated reporting and a system that can give you the track report of supplier relationship management. To ensure that you have achieved the total value, you must monitor the company’s purchases constantly, as not being able to accomplish that can result in losing savings.

It is essential to understand that strategic Sourcing is a complex process, as it takes time and effort to receive the pattern of the supply market. It also takes much hard work to restart the process if you find flaws that need to be corrected. The market conditions can change, and the category’s benchmark can lead from this point.

Strategic Sourcing Plan

As the term indicates, a sourcing plan is the process of planning in which all the events are well organized and even have further details. The details depend on all the information, which is tactical, technical and operational as well. It also includes the information of the sourcing team, which handles all the responsibilities of the event. The main starting and ending date of the event is also included here. The beginning and end dates of the projects depend on the RFX steps, which are essential for strategic sourcing. RFI, RFP and RFQ steps, with other requirements and different materials specifications with services, are all parts of the strategic sourcing plan.

It also has information about the negotiation goals for meaning the time and the overall quality of the events conducted to improve sourcing. Here the main element of planning is a practical approach which is possible when the professionals start using spreadsheets for writing the RFX activities as it lowers the risks and errors attached to the sourcing process.

Sourcing Business Models

Structuring the relationship with the supplier is highly important in sourcing business models as it offers a proper system to the companies. Hence, two different parties engage with each other in sourcing business models to achieve more success. Experts have identified and designed seven sourcing business systems that vary in diversity from mainly transactional to more concerned investment.

Following are the business models.

- Primary provider

- Authorized provider

- Elected provider

- Performance-based service model

- Hybrid vested outsourcing business model

- Communal services model

- Fair play Partnership Model

Procurement professionals seeking the best modern and practical approach can use the sourcing business model to achieve the most suitable model that suits all possible buyers and credible suppliers.

How to Conduct Strategic Sourcing?

Strategic Sourcing is a process based on a consistent effort to improve and re-evaluate the activities related to the purchase of products. The process’s main objectives are to save maximum money and reduce risk. The process consists of 7 steps of practice which are categorized here.

- Create a sourcing category that identifies the volume of products and services, existing costs, and other specifications. The class also has information about the user’s location and all of the company’s supply chain departments.

- Analyze the supply market by seeing its existing performance. Here the main task is to determine your approach to see whether it suits the specific type of Sourcing. Figuring out effective ways to assess risks and profitability connected with the purchase is essential. Segmenting the company’s products and different services helps see its potential over the status of the company.

- Establish a strategic sourcing blueprint to determine how to purchase the product while considering the minimum risk associated with the cost. This is also a point where a cross-functional team has to identify the potential suppliers and develop the goals that the company wants to achieve.

- Choose the strategic sourcing process by using Request for Proposal, which is based on a legal document that displays solicit proposals. Such proposals should have detailed information about the specification of the products and services, including the cost and terms and conditions to purchase them.

- Settle the legal matters, and select potential suppliers responding well to RFP. The company can conduct interviews with the suppliers.

- Implement and integrate strategic Sourcing by communicating all the details and terms and conditions with the suppliers. If you would have a complex product, then the level of partnership required by the supplier would also be different.

- Set a benchmark of performance even by evaluating the performance of the supplier. The company can also see the current status of the services and the product it intends to sell and see whether the goals set have been achieved with time. This methodology can help the users identify and solve the issue.

How to improve Strategic Sourcing?

To follow a more sustainable plan toward achieving more profit, businesses can work on some of the areas in which they can improve their strategic Sourcing. The following are some areas through which companies can enhance strategic Sourcing.

- Analyze the existing Sourcing process by using References for Information and another famous method named Request for Proposal, which is very comprehensive and has information such as specifications, price, legal terms, and the service requirements of the products. This helps in seeing the hidden cost and other irregularities of products.

- Determine the area of a company’s spending by identifying the different sections of expenditures and categorizing the cost efficiencies to all suppliers that maintain the supply chain, which can help reduce the cost of the products.

- Evaluate the performance of the supply market to know which suppliers are available and to see the tendency of leverage in the market. The evaluation also helps in seeing the price of switching suppliers and the government-level regulations that can impact the suppliers overall.

All three steps show that the process can improve by differentiating the market and seeing the present growth rate. However, commitment to increasing the efficiency of strategic sourcing is also essential and can be done simultaneously.

Strategic Sourcing Vs Sourcing

The sourcing strategy is more uncomplicated as it only deals with searching for a profitable supplier of the services. Supply chain management is one example of a sourcing strategy.

On the other hand, strategic Sourcing is also the supply chain management process. Still, it focuses more on obtaining the highest value in the company’s decisions to purchase products and services.

7. Report and Track the Results

The primary benefit of strategic sourcing is increasing the awareness among different manufacturers for improving relationships with the suppliers. This relationship mainly depends on communication with the supplier about the goals and targets of the business and collaboration with them to achieve the goals. Following are some of the main benefits identified in strategic sourcing that can help one identify its importance.

- Cost Saving

- Risk Mitigation

- Continuous Improvement

- Alignment with Business Objectives

- Optimization & Recognition of Ideal Suppliers

Challenges Organizations Face While Implementing Strategic Sourcing

The biggest challenge faced by companies to implement strategic Sourcing is the technology that works at a slow pace, stops the workflow, and takes the process to manual handling. Two other significant challenges faced by companies are described further here.

- Management of suppliers means maintaining the relationship through analyzing the performance formally or professionally.

- Correct estimation of product demand and overall cost that impacts business objectives. It is necessary to have accurate information to help others process the users.

Learn more about- eProcurement

Steps in Strategic Sourcing

What Is Tactical & Strategic Sourcing & What Are the Differences?

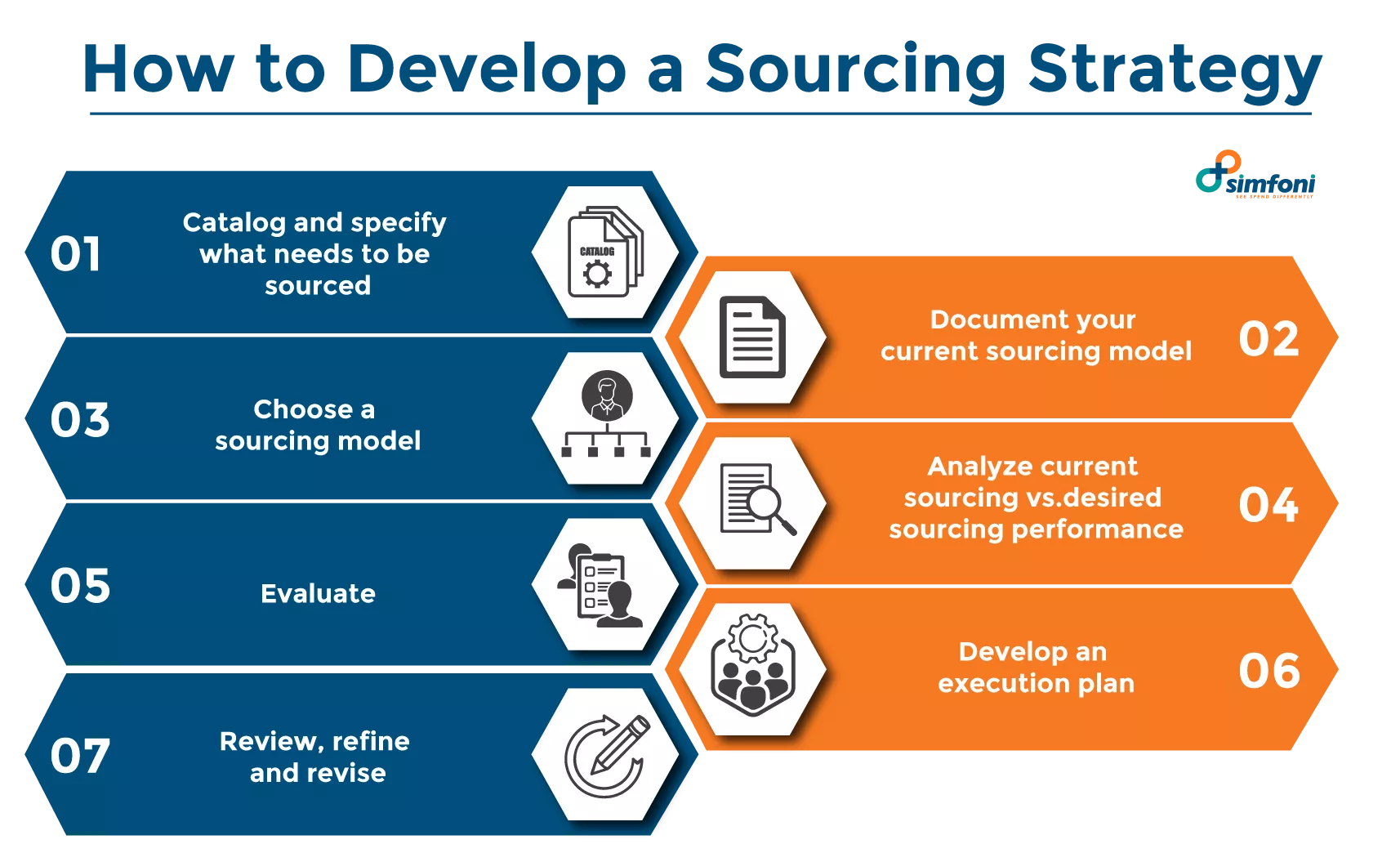

How to Develop a Sourcing Strategy?

So, how do you practically source quality suppliers? The first step always starts with creating a solid sourcing strategy.

Generally, procurement teams need a long-term sourcing strategy that details how the business will establish and uphold the continuous flow of the targeted goods and services to your company’s supply process. Additionally, the strategy must address how you will edge out the competition looking for the same goods and services.

But is there really a need for a sourcing strategy? The answer is yes! So, how do you get started?

Here are the steps to writing a sourcing strategy

Conclusion: Simfoni’s eSourcing Solution

An excellent and strategic sourcing process is essential to the success of any business. Still, more than that, the implementation of automation in the sourcing process will bring immense benefits.

Simfoni’s eSourcing solution removes the inefficient, labor-intensive processes of traditional sourcing and replaces them with a unique combination of powerful, AI-backed technology and experienced sourcing professionals.

Say goodbye to problematic guesswork and manual spreadsheet analysis, time-consuming drilling through numerous spend and operations categories, or countless contract comparisons. Simfoni makes it easy to improve spend management at the source.

As a cloud-based platform, Simfoni delivers a future-proofed, right-sizing spend management solution that puts you in control of your spend from the start. With our composable architecture, Simfoni lets you mix, match, and create your perfect platform using a wide array of sourcing and spend management modules and tools.

Run RFx events and combine them with any of Simfoni’s seamlessly integrated eAuction, auto-scoring, dynamic bidding, or decision support tools, all to manage, enhance and meet your organization’s unique sourcing and business goals. What’s more, Simfoni gets you up & running fast and will scale to meet your exact needs. By automating your sourcing process, you ensure your business’s success.

Strategic Sourcing is a way companies can flourish by having a routine eye over their operations using the latest technology with the help of influential professionals and suppliers. It is a process that gives power to the companies as they can grow a strategy by selecting a satisfying method and leading with the supplier on legal terms. It also helps achieve maximum benefits as the continuous evaluation develops a more sustainable cycle of supplier performance and the purchase of products and services.

Frequently Asked Question (FAQ)

For your help, we have created a list of answers to assist you more.

What is Strategic Sourcing?

Strategic sourcing is defined as a comprehensive procurement process aimed at enabling organizations to maximize their purchasing power and achieve efficiencies across all spend categories. This approach involves various key elements:

Data Collection and Analysis: It begins with collecting and analyzing data related to an organization’s current supply chain and spending patterns.

Market Research: Strategic sourcing includes market research to identify potential suppliers and market trends.

Negotiation: It involves negotiations with suppliers to secure favorable terms, pricing, and agreements.

Contracting: Strategic sourcing formalizes agreements and contracts with selected suppliers.

Alignment with Business Goals: The process ensures alignment between the organization’s business requirements and its supplier base to optimize various aspects, including performance, cost savings, quality assurance, delivery timeframes, and compliance standards.

Risk Mitigation: Strategic sourcing minimizes supply risks by carefully selecting suppliers.

Visibility and Forecasting: It provides visibility into pricing and forecasting, helping organizations make informed procurement decisions.

Strategic sourcing does not encompass the actual purchase and payment for goods and services but focuses on the strategic planning and decision-making leading up to procurement. It is a systematic approach to supply chain management that allows organizations to leverage their purchasing power, make informed decisions, and align their procurement strategy with their business objectives. Ultimately, strategic sourcing aims to maximize the value obtained from purchasing decisions.

What is an example of strategic sourcing?

A practical illustration of strategic sourcing occurs when a manufacturing company assesses its suppliers for essential raw materials, like steel. During this evaluation, the company takes into account several key factors, including supplier performance, the quality of the products, pricing structures, and reliability. After this assessment, they may opt to streamline their supplier portfolio, engage in more favorable pricing negotiations, and foster enduring partnerships with specific suppliers. This strategic methodology enables the company to secure a consistent supply of top-notch steel at competitive rates, consequently enhancing both cost-effectiveness and product quality.

What are the 7 steps of strategic sourcing?

The seven steps of strategic sourcing typically include:

- Identification of Needs: Define the specific needs and requirements for goods or services.

- Market Research: Analyze the market to identify potential suppliers and market conditions.

- Supplier Evaluation: Assess and evaluate potential suppliers based on various criteria.

- Negotiation: Negotiate terms, pricing, and contracts with selected suppliers.

- Contracting: Formalize agreements and contracts with chosen suppliers.

- Implementation: Integrate the selected suppliers into the supply chain and monitor their performance.

- Continuous Improvement: Continuously monitor and evaluate supplier performance, making adjustments and improvements as necessary to optimize the sourcing process.

What are the 4 pillars of strategic sourcing?

The four pillars of strategic sourcing are:

- Supplier Selection: The process of identifying and opting for suppliers is rooted in specific criteria, encompassing quality, cost, reliability, and performance standards.

- Cost Management: The primary emphasis here is on implementing strategies geared towards cost reduction and maintaining control over expenditures, thereby optimizing cost-efficiency throughout the sourcing process.

- Risk Mitigation: The proactive identification and resolution of potential risks within the supply chain, which may include addressing supply disruptions, quality concerns, or geopolitical factors.

- Supplier Relationship Management (SRM): The strategic cultivation and sustained nurturing of cooperative and robust relationships with chosen suppliers. This fosters long-term value, encourages innovation, and establishes a foundation for mutual success.

What are the five steps of strategic sourcing?

The five steps of strategic sourcing often include:

- Assessment: Analyze the organization’s current sourcing practices and needs, identifying areas for improvement.

- Strategy Development: Develop a sourcing strategy aligned with business goals and objectives, considering factors like cost savings, quality, and risk mitigation.

- Market Analysis: Conduct research to identify potential suppliers, assess market conditions, and evaluate supplier capabilities.

- Negotiation and Contracting: Negotiate terms, pricing, and contracts with selected suppliers, ensuring they align with the sourcing strategy.

- Implementation and Performance Management: Integrate chosen suppliers into the supply chain, monitor their performance, and make continuous improvements to achieve the desired outcomes.

How does strategic sourcing identify and expand potential suppliers without compromising quality?

Strategic sourcing assesses supplier core competencies and creates profiles to meet complex requirements. This process identifies high-value suppliers, fostering their growth in a way that benefits businesses without compromising quality.

How does strategic sourcing foster transparent relationships with suppliers?

Strategic sourcing emphasizes building strong, transparent relationships with suppliers, involving them in critical decisions. Effective communication and collaboration enhance supplier performance, aligning with business objectives.

What are the key steps involved in implementing strategic sourcing?

Implementing strategic sourcing involves a structured six-step process: stakeholder commitment, supplier engagement (RFx), specification of evaluation criteria, a highly preferable bidding process, supplier selection, and formalizing the supplier relationship.

Can you outline the six-step methodology used in strategic sourcing?

The six-step methodology in strategic sourcing includes defining company requirements, gathering and analyzing data, developing a sourcing plan, obtaining approval, managing sourcing contracts, and overseeing supplier relationships.

How does eSourcing software enhance strategic sourcing practices?

eSourcing software streamlines strategic sourcing activities by improving data reporting and visibility, managing spending categories effectively, assessing supply chain risks, and enhancing project accountability.

Why do supply chain managers embrace strategic sourcing?

Supply chain managers adopt strategic sourcing to optimize costs while enhancing the quality of goods and services. It helps in identifying reliable suppliers, cultivating positive relationships, and staying updated with industry trends.

How does strategic sourcing assist in supplier classification?

Strategic sourcing classifies suppliers based on their suitability for different scenarios and their potential to contribute to product differentiation. This classification ensures a consistent supply of materials and opportunities for competitive distinction.

Why is fostering positive supplier relationships a priority in strategic sourcing?

Fostering positive supplier relationships is crucial for ensuring material quality and building trust with consumers. Ethical practices and transparent dealings are essential in today’s competitive market.

How does strategic sourcing encourage skill development?

Strategic sourcing motivates professionals to maximize their skills and stay current with industry trends. It enhances supply chain infrastructure, reduces costs, and ultimately bolsters the company’s market position.

Why is continuous learning pivotal in strategic sourcing?

Continuous learning in strategic sourcing helps professionals make well-informed decisions at different stages. It identifies challenges and opportunities, leading to competitive advantages and improved sourcing strategies.

How does strategic sourcing adapt to evolving business conditions?

Strategic sourcing relies on adaptability and flexibility to address internal and external challenges that may impact sourcing strategies. It ensures that businesses can adjust to changing conditions and make informed decisions.

Useful Resources

- Cost Reduction Strategies in Procurement.

- Effective Procure-to-Pay Process Guide (P2P Procurement).

- Guide to eProcurement software & Solutions.

- Guide to Manage Tail Spend and Improve the Bottom Line.

- Guide to Procurement Software & eProcurement Solution.

- Guide to Understanding Category Management in Procurement.

- Leveraging AI & Machine Learning in Procurement.

- Procurement Analytics & Implementation.

- Procurement Management - Key Steps and Roles.

- Procurement Marketplace - Reinventing Procurement

- Savings Tracking Process in Procurement.

- Source to Pay Process, Steps & Definition.

- Spend Analysis in Procurement: Importance, Process & Examples.

- Supplier Diversity in Procurement

- Sustainable Procurement - Importance & Best Practices

- Understanding the What, Why, & How of Strategic Sourcing.

- Procurement Auctions – How It Works, Example, and Risks.

- Supply Chain Management (SCM): How It Works and Why It Is Important

- What is Contract Management - Everything You Need to Know

- B2B Marketplace - The Ultimate Guide to Procurement Marketplace

- Spend Management - Importance & Best Practices On Business Spend Management Software & Solutions

- Strategic Sourcing – Ultimate Guide To Strategic Sourcing Processes

- Spend Cube – Ultimate Guide to Spend Cube Analysis

- Procurement Software - Automate Your Procurement Process