Table of Contents

Introduction to Sourcing

Sourcing in procurement is defined as a process to find, evaluate, and engage suppliers based on set criteria to achieve cost savings and best value for goods and services at a price point & terms that give the required margin to positively affect the company’s bottom line. The sourcing process is carried out using a tendering process and is applied at tactical and strategic levels with the intent to create distinctive value by finding the most appropriate suppliers at the lowest cost to gain a competitive advantage.

Simfoni.com Tweet

In most organizations, the process of sourcing products or services is the first step in the supply chain process. Sourcing involves finding a balance between the quality of products and raw materials required and affordability. The goal for most procurement teams is to spend less and increase the bottom line.

But how can you ensure that you have the right strategies and techniques to make sourcing a profitable process?

In this sourcing 101 guide, we break down everything involved with sourcing, from finding products to finding the most suitable suppliers to buy those products from, right through to the delivery types involved from sourced supplier to customer. So, let’s dive in.

What is Sourcing?

We’ll start the guide with a comprehensive definition of what sourcing is.

Typically, sourcing is finding the most suitable supplier that provides the quality of goods or services at a price point that gives the business owner the profit margins they need. Sourcing and procurement management fit together like hand and glove. But before you can procure goods, it is essential to:

- Find prospective suppliers

- Implement a rigid vetting process

This ensures that no mistakes are made during the sourcing process because it can be costly to backtrack. While most business leaders focus primarily on the cost reduction benefits of strategic sourcing, in today’s competitive market, leading companies have begun to look at creating value while not ignoring cost and waste reduction.

Three factors are central to the sourcing process, and these are:

- Cost structure

- Profit margins

- Competitiveness

All three factors affect businesses of all sizes.

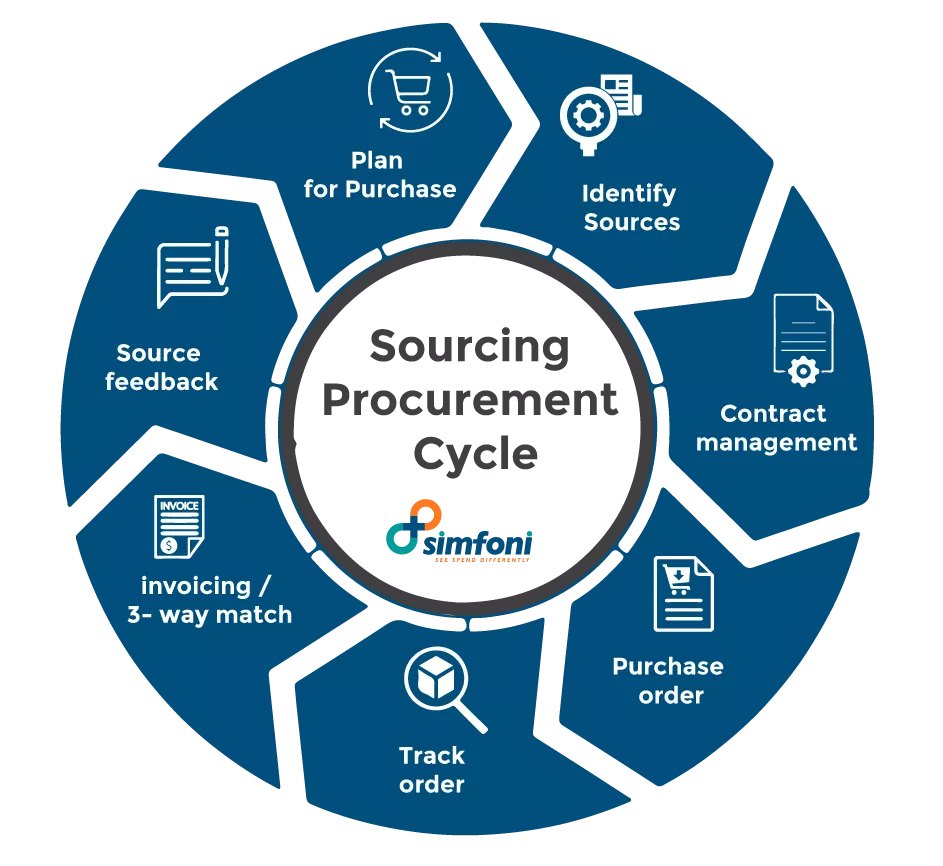

The sourcing process involves:

- Collecting data on good quality sources of goods and services

- Negotiating contracts

- Market research

- Product testing for quality

- Considering outsourcing for goods

- Constituting standards that the company will use.

You must keep in mind that the end goal of sourcing is procurement. Steps in the procurement process include:

- Logistics

- Communications

- Negotiations

Different types of Sourcing

To implement successful sourcing, you must have a thorough understanding of your entire business strategy, i.e., you need to know what resources are required to deliver that strategy and the market forces and specific risks associated with implementing particular approaches.

Acquiring cheap goods and services should not be the only goal of sourcing. Instead, procurement teams should center sourcing activities around developing mutually beneficial relationships. Depending on your sourcing needs and the goods you are trying to acquire, you can choose to work directly with wholesalers, manufacturers, or sources from distributors.

That said, what types of sourcing should you consider?

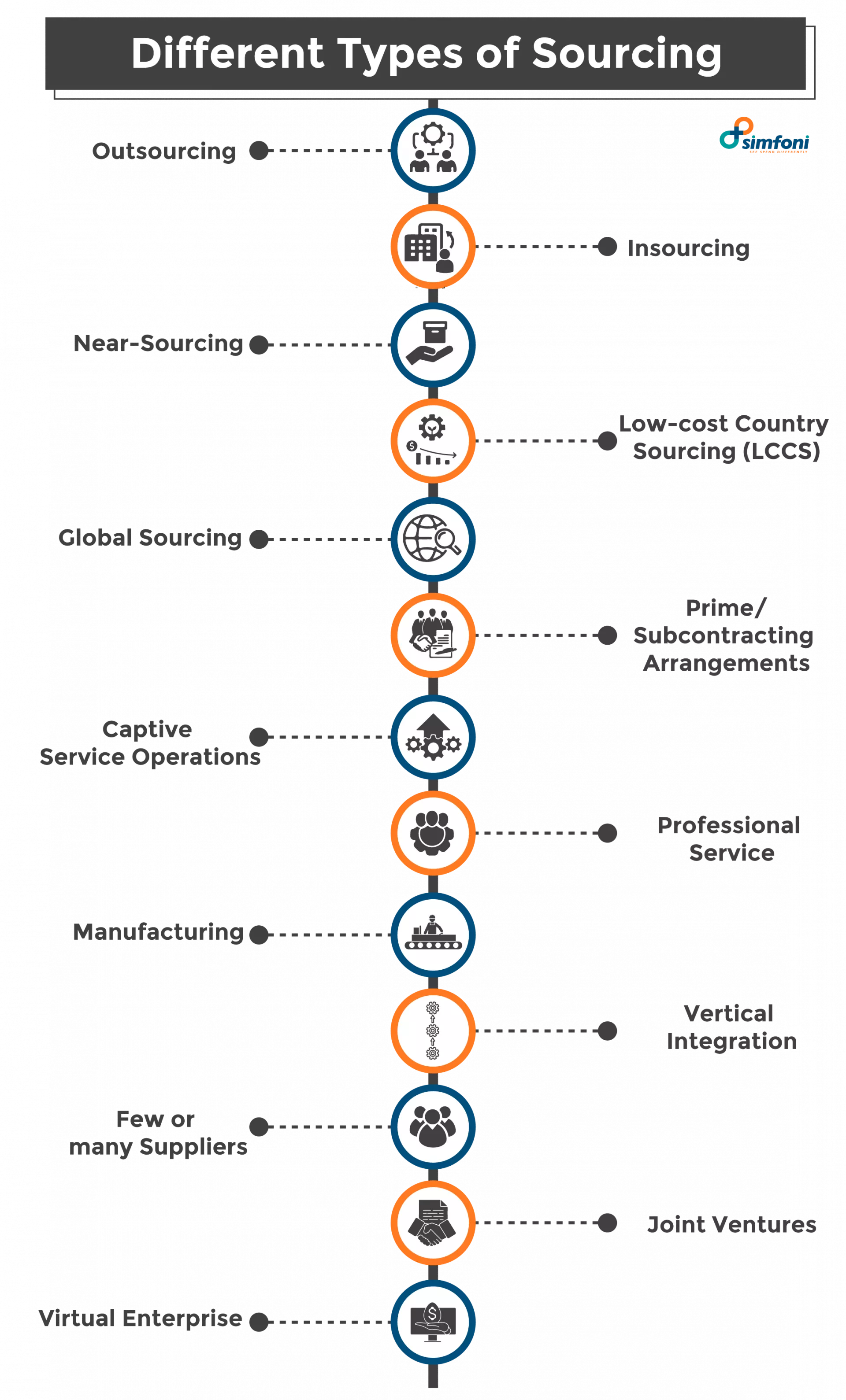

1. Outsourcing

The most practical and straightforward example would be hiring a party outside a company to perform services or create goods that were traditionally performed in-house. This can also be done by migrating operations abroad or partnering with a domestic supplier. Both back and front office functions can be outsourced.

2. Insourcing

This type of sourcing involves you delegating a job to someone or a team within the company. Most company leaders prefer this option when available because it is an excellent cost-saving strategy that allows for on-the-ground monitoring of the quality of goods and services required.

3. Near-sourcing

This involves placing some of your operations close to where your end-products are sold.

4. Low-cost Country Sourcing (LCCS)

LCCS involves sourcing materials from countries with lower labor and production costs. This type of sourcing focuses on cutting down the overall operating expenses of an organization. China has become the go-to country for this sourcing method for most global corporations.

5. Global Sourcing

The world is now one giant marketplace. Buying goods and services from international markets across geopolitical boundaries has become an easy process. This method has many benefits and exposes your organization to different markets; moreover, you gain insight into how business is conducted worldwide.

You also can access a new range of skills and resources that may not be readily available in your country.

6. Prime/Subcontracting Arrangements

This arrangement involves a contract between a contractor and a subcontractor to perform a portion of work that is part of a larger project. All contracts are dealt under offshore law because the agreement is between two offshore entities. Procurement teams can reduce the burden of dealing with import or export restrictions

7. Captive Service Operations

Some organizations go as far as establishing and operating some form of a partly/ wholly-owned entity overseas. This method makes room for greater control and allows you to control confidentiality and security issues. However, your economies of scale will be negatively affected.

8. Professional Service

You can recruit the professional services of occupations in the service sector requiring special training.

9. Manufacturing

The creation of new products either from raw materials or components.

10. Vertical Integration

Involves the merging of companies at different production and/or distribution stages in the same industry. So, when a company acquires its input supplier, it is called backward integration; it is called forward integration when it acquires companies in its distribution chain.

11. Few or many Suppliers

A multi-supplier strategy is commonly used for commodity products, and purchasing is typically based on price. On the other hand, single-source purchasing refers to purchases from one selected supplier, even though other suppliers provide similar products. Sole-source procurement refers to purchases with only one supplier.

12. Joint Ventures

This is a business entity created by two or more parties. It is generally characterized by shared ownership, returns and risks, and governance.

13. Virtual Enterprise

This is when a network of independent companies (i.e., suppliers, customers, competitors) are linked by information technology to share skills, costs, and access to one another’s markets.

As you can see, there are many types of sourcing. The various options mean that the management of these relationships differs significantly.

Responsible Sourcing

Responsible sourcing has become a hot topic in today’s global supply chain market. This type of sourcing is a voluntary commitment by companies to consider social and environmental considerations when managing their relationships with suppliers.

The modern consumer and investors are increasingly mindful of the ethical creation and sustainability of a product. They are more likely to invest in more socially sustainable goods and services than ever. Sourcing teams and company leaders who want to remain competitive and protect their brand have to incorporate social, environmental, and ethical practices in their business, taking responsibility for the entire life cycle of products and protecting workers’ rights during the production process.

But this is easier said than done. The complexity of global supply chains can make it difficult for companies to be aware of or understand the potential risks affecting their business and their suppliers.

Thankfully there is a solution. Your business needs to be able to trace a product or service through each stage of the supply chain and work with their company and suppliers to ensure working conditions are fair and environmental practices are sustainable.

What is Impact Sourcing?

Another modern trend in sourcing is impact sourcing. This type of sourcing is a socially responsible arm of the Business Process Outsourcing (BPO) and Information Technology Outsourcing industry that aims to employ people with limited opportunities for sustainable employment.

The impact sourcing sector utilizes workers from poor and vulnerable communities to perform functions with lower and moderate skill requirements such as scanning documents, data entry work, data verification and cleaning, video tagging, and microwork.

Sourcing Models

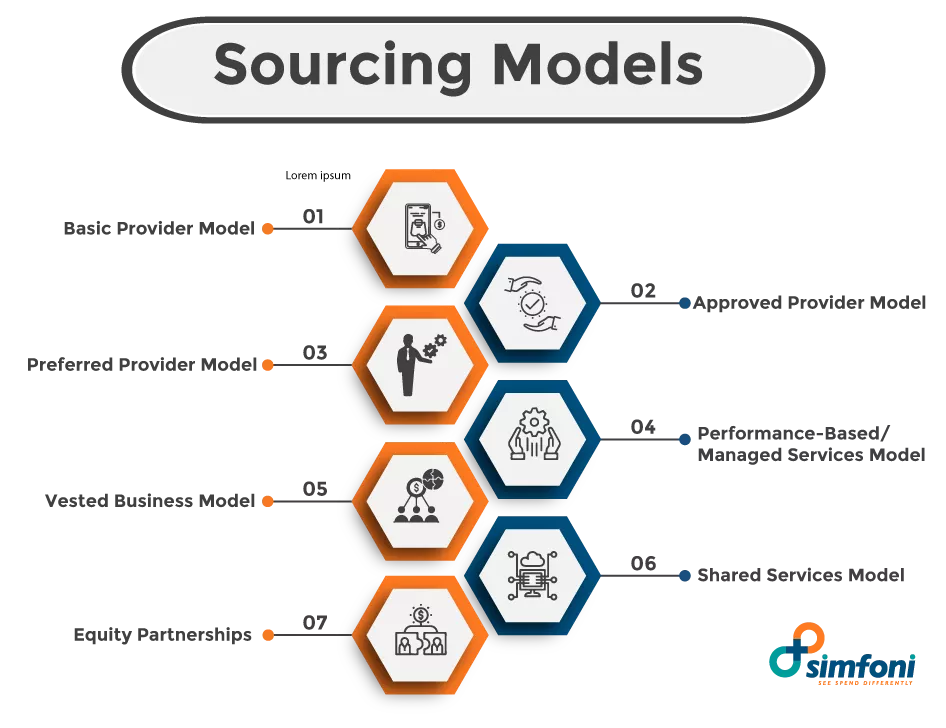

A sourcing business model combines a company’s relationship model and defines how you will formally control your supply source and economic model. This, in turn, determines how you will handle the economics of the relationship. The 7 Sourcing Business Models are:

1. Basic Provider Model:

Used when the primary purpose is to purchase goods and services at the lowest possible cost.

2. Approved Provider Model:

Used when you want to take advantage of high-volume discounts with suppliers with a proven track record.

3. Preferred Provider Model:

Offers value-added capabilities or volume discounts with a set supplier, and this is usually due to a longer contract.

4. Performance-Based/ Managed Services Model:

This is dependent on the supplier who has to drive efficiency and deliver predefined service levels. This model allows for a longer contract as the supplier tends to benefit as long as they sustain the quality of their goods or services.

5. Vested Business Model:

Is a collaborative model that requires both sides to ensure that everyone is committed to the success of the other. These relationships tend to last well over 10 years and optimize innovation and risk management.

6. Shared Services Model:

Is an investment-based model that is developed by companies that are seeking to create their own internal supplier

7. Equity Partnerships:

Are legally binding through formal structures. In this model, the organization invests directly into another company to build capability.

Why is Sourcing Important?

The first step in getting the supply chain right is sourcing the products and services. There is also a need to balance the quality of the products and the raw materials that one needs. Moreover, affordability of the products is also an aspect that needs to be considered where sourcing is concerned, as it directly impacts the bottom line.

A well-executed sourcing process allows your company to establish consistent and predictable supply chains; in turn, shelves stay well-stocked, keeping customers happy. When sourcing is done right, it can positively affect your brand image and help create brand loyalty.

Strategic sourcing also helps in cost management by providing benefits for both the buyers and the suppliers. Negotiating lower unit pricing for high volume purchasing reduces the cost of goods. It allows the business to keep its pricing competitive. On the other hand, the suppliers benefit by having a consistent outlet for their goods, making planning and cash flow more dependable.

Benefits of Sourcing

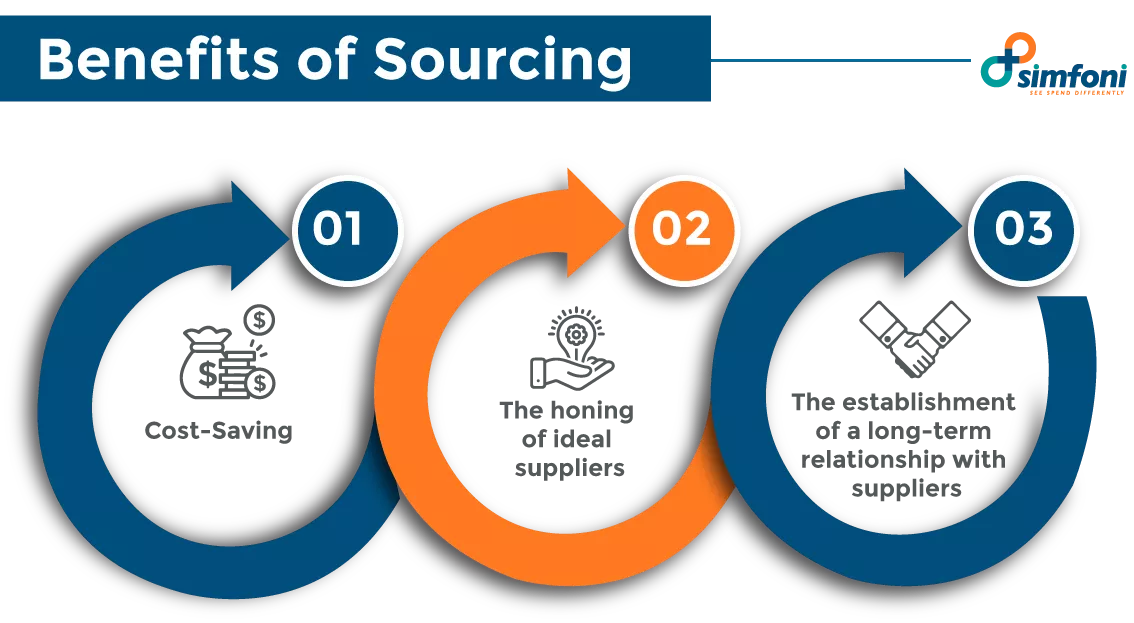

The four benefits of sourcing are:

1. Cost-Saving

The first and most popular benefit of strategic sourcing is the amount of money that organizations can save by selecting and choosing suppliers that will offer the highest value at the best price possible. This will have a domino effect and positively affect your bottom line.

2. The honing of ideal suppliers

Effective implementation of a sourcing process has its foundation on the quality of the suppliers involved. Procurement teams should have on-hand supplier profiles and understand the core capabilities of the suppliers they choose. This allows you to match your organization’s objectives with your ideal supplier resulting in the highest value creation at the lowest possible cost.

3. The establishment of a long-term relationship with suppliers

When suppliers are valued and considered in various sourcing decisions, they will feel motivated and optimize their performance to meet your organization’s objectives.

Diversity and Inclusion in Procurement and Sourcing

Establishing diverse supply chains can have significant benefits for your company. Aside from increasing revenue, diverse and inclusive supply chains are more competitive, encourage innovation, provide new markets opportunities and deliver socioeconomic impact in local operating markets.

So how can you accelerate supply chain diversity in your company?

1. Determine where your procurement dollars are going

Developing a basic understanding of external procurement expenses is essential to building a more diverse and inclusive supply chain.

2. Identify diverse suppliers aligned with crucial spend categories.

Once you understand the significant categories of spend, you can begin broadening your pool of potential suppliers within each category. Look for platforms that can connect you with diverse suppliers. Advocacy and diversity certification organizations are an excellent place to start.

3. Establish inclusive procurement policies.

Ensure that you choose at least one diverse supplier in competitive supplier selection/RFP processes.

Procurement vs. Sourcing: What's the Difference?

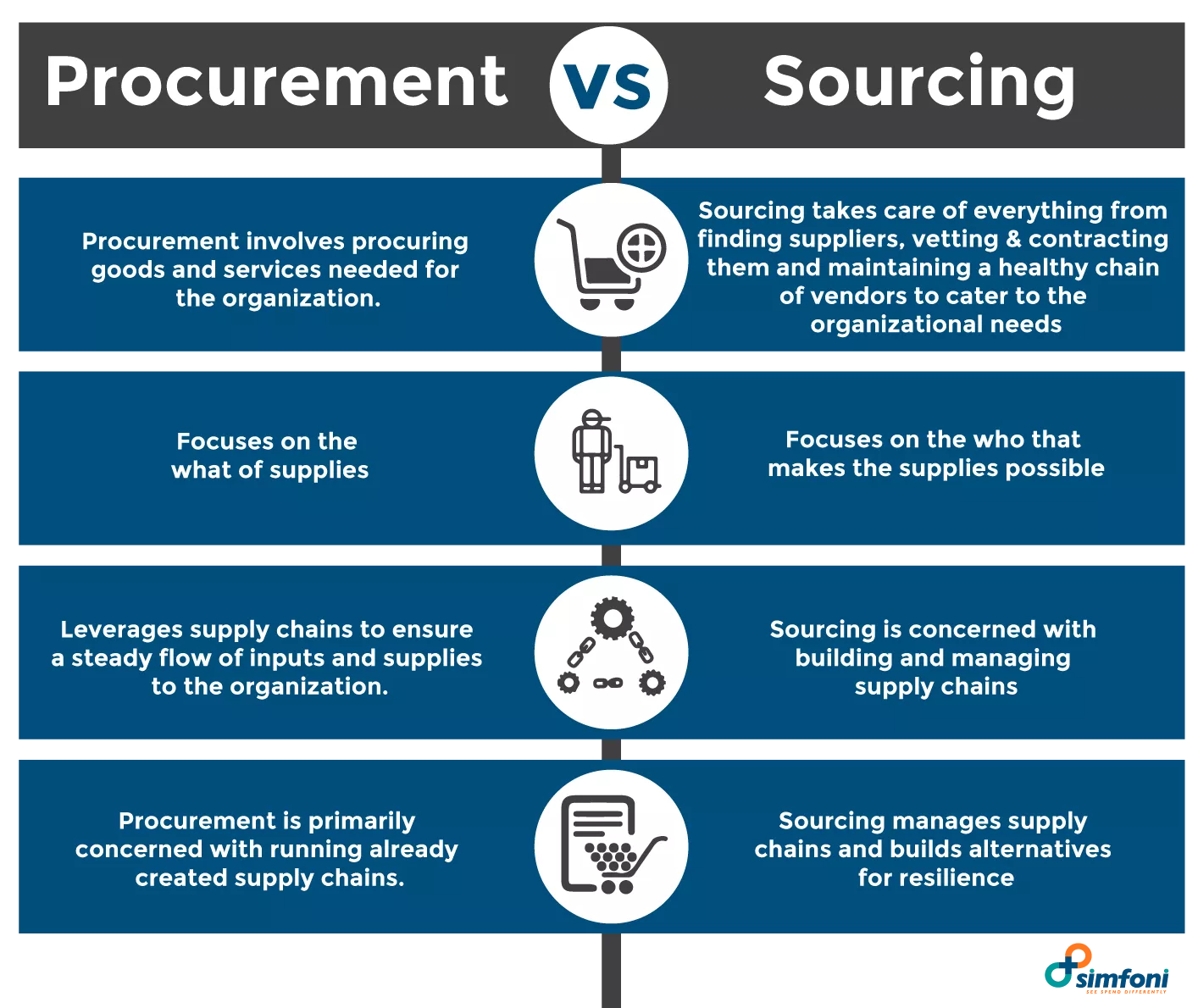

There tends to be a little confusion where terms like procurement, purchasing, and sourcing are concerned. The terminology is related and sometimes used interchangeably, but each has a distinct meaning.

As a procurement or business leader, you need a complete understanding of the differences to help you gain a better understanding of the sourcing process. So, without further a due, let’s establish the differences.

Typically, procurement is concerned with acquiring the goods and services that are vital to an organization. Procurement is tasked with acquiring high-quality goods at the right time to meet company needs. The procurement process helps you gain insight and control over your company’s spending habits, minimize errors and fraudulent spending and boost efficiency by streamlining procure-to-pay-cycle.

Procurement involves multiple processes and numerous steps such as:

- Needs recognition

- Requesting goods and services

- Review and approval

- Sourcing

- Purchase order

- Receipt of goods or services

- Receipt of invoice

- Pay invoice

On the other hand, sourcing focuses on finding the best possible supplier of goods and services and negotiating the most favorable contract terms.

Sourcing involves:

- Defining the need

- Researching the market

- Running sourcing events

- Vetting suppliers

Sourcing vs. Procurement Differences

Process Components

Sourcing is a subprocess of procurement and comes before any purchases are made. Sourcing ensures that the lowest purchase price is found while developing supply channels that provide the most significant value. To summarize, sourcing adds value to the procurement cycle by establishing solid supplier relations that help ensure consistent quality and availability of products or services.

Sourcing is less complex and has fewer moving components. It involves defining internal requirements, searching for vendors, arranging sourcing events, and assessing suppliers.

While procurement encompasses the sourcing process itself, purchasing, data analysis, contract and supplier relationship management.

Timing

The timing of both processes is different as sourcing takes place before the purchase is made or if there is a problem during the purchasing process.

On the other hand, Procurement is an end-to-end process covering all the activities before, during, and after purchasing.

Goals and Focus

The goals and focus of procurement and sourcing are also different. Sourcing is concerned with establishing relationships with the most suitable suppliers and building and maintaining a dependable supply chain. On the other hand, the procurement process combines strategic and tactical components.

Procurement mainly concerns purchasing high-quality goods and services at the lowest possible price while satisfying internal requirements. In summary, sourcing is concerned with suppliers, while procurement focuses on buying goods and services.

Function

Sourcing is meant to support procurement by building supply chains and systems for procurement professionals to use.

Sourcing teams focus on developing relationships with vendors, while procurement teams use vendor relations to purchase goods.

Therefore, sourcing makes the flow of supplies possible, whereas procurement aims at streamlining and optimizing this flow.

The sourcing team negotiates the pricing and quantity of products and goods with suppliers, and then the procurement team uses this information to predict the spend and determine how much money can be allocated.

What is Strategic Sourcing?

Globalization has magnified the level of competition in the business arenas. Therefore, it has become paramount for organizations to leverage the power of globalization and improve performance. Therefore, the role of effectively sourcing goods and services from suppliers has become unavoidable.

The need for an effective and strategic sourcing process that enhances an organization’s performance and efficiency has increased due to the volatility of the global market.

So, in essence, strategic sourcing refers to the process of identifying your spend profile and supplier base to ensure that your business requirements are aligned with the suppliers. This is a proactive, holistic, and continuous evaluation and re-evaluation of the sourcing activities in your organization.

Strategic sourcing aims to decrease supply chain risk, forcing procurement teams to develop strong and positive relationships with their sourcing partners. The supplier is viewed as a crucial value partner that collaborates with the organization.

Lastly, with strategic sourcing, there is more intensive monitoring of the customer-supplier loop at every stage of its lifecycle. This means there needs to be:

- Spend analysis

- Supplier evaluation

- Supplier relationship management

- Detailed market research

This means that strategic sourcing is a long-term process and needs skilled personnel and relevant technology platforms and tools to become successful.

Learn more about- eProcurement

Benefits of Strategic Sourcing

- It increases the level of cost savings achieved by identifying and selecting suppliers that will provide the highest value at the best price.

- It allows buyers to negotiate lower unit prices for his-volume purchases, thereby reducing the cost of goods sold.

- It allows your organization to stay competitive where prices are concerned and provides continuous higher cost savings.

- It benefits the suppliers who have the assurance of predictable orders and long-term cash flow visibility.

- Companies that implement strategic sourcing have more time to focus on the core activities of the business.

- Strategic sourcing helps build stable supply partnerships, especially for businesses that rely on disruption-prone goods and services.

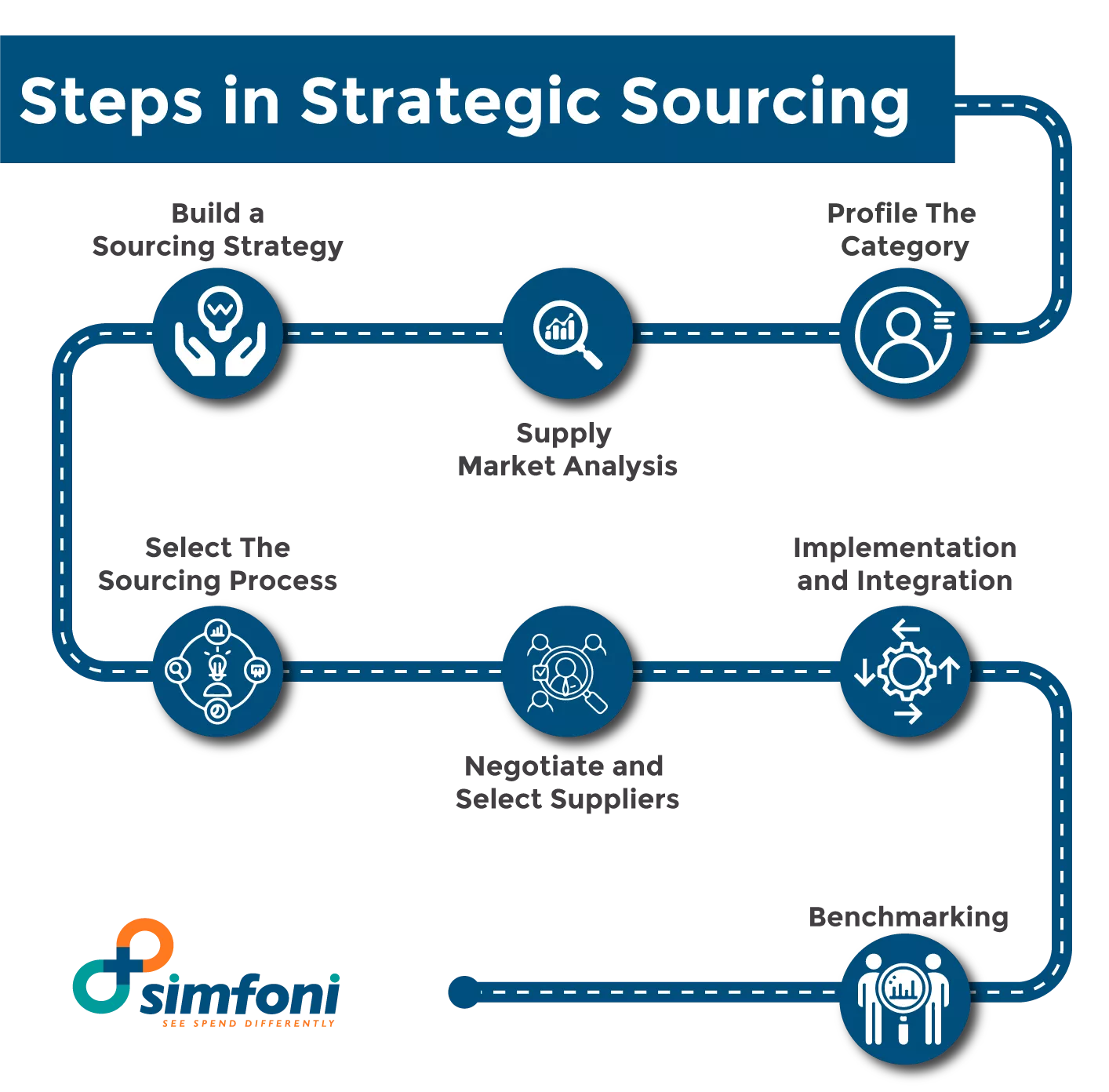

Steps in Strategic Sourcing

To effectively implement strategic sourcing in your organization, there are seven crucial steps you should take, including

- Building a sourcing strategy

- Analysis of supplier market

- Request for supplier information and identification of selection criteria

- Selection of suppliers and execution of contracting process

- Measurement and periodic tracking of supplier performance

- Implementation of supplier relationship management

- Identification and Categorization of Spend Profiles

1. Profile The Category

The first step is identifying the sourcing category or commodity, such as the quantity, types, and sizes of products, and determining how much was spent on products and services, current prices and suppliers, and specifications. This step also involves the creation of user profiles. For example, who they are, where they are located – and departments involved in the supply chain.

2. Supply Market Analysis

Next, you need to understand your buyer power and category to position the sourcing strategy. This involves performing a market analysis to help you determine what strategy approach better fits with the type of service you’re sourcing.

Kraljic’s Matrix is an effective method to categorize your vendors. This two-by-two matrix is mapped against two key dimensions: risk and profitability, where risk demonstrates the likelihood of unexpected events occurring that may disrupt the operations, and profitability describes the possibility of impacting the organization’s bottom line.

Once a product or service is segmented, you’ll have a better picture of how it will impact your business.

3. Build a Sourcing Strategy

In this step, you need to decide where and how to buy while minimizing the risk and cost. To get the best out of your supplier pool, you should consider both existing and potential suppliers. Make sure that you establish your business goals and the minimum requirements for suppliers.

Once you’re done with that process, you’ll have to develop selection criteria based on the suppliers that suit your requirements, capabilities, and resources.

4. Select The Sourcing Process

Now comes the time to solicit bids. Generally, many businesses use the Request for Proposal (RFP). This document solicits proposals, which is often used through a bidding process. It is written internally by your procurement team. It outlines the details of product or service specifications, requirements, pricing breakdown, legal and financial terms and conditions, and evaluation criteria.

5. Negotiate and Select Suppliers

Typically, you’ll have a whole host of suppliers that respond to your RFP. So, you need to ensure that you shortlist the most potential suppliers, then interview for clarification or asking more details if required. The more information you gather from each supplier, the better your decision.

Moreover, all information can also be easily accessed if necessary, reducing or eliminating long email chains and lengthy conference calls.

6. Implementation and Integration

After negotiation, the next step is to choose the suppliers you want to partner with. Just make sure that you notify the suppliers that will be involved in the implementation stage.

It’s essential to involve your suppliers in your meetings or discussions during the implementation stage, ensuring they are in the loop.

7. Benchmarking

It is essential to measure the supplier’s performance over time – starting with benchmarking the current status of the product, continuously monitoring the results, and ensuring the goal is being achieved. By doing so, you can quickly identify any issues during implementation and notify your supplier to address the problem in a way that has the lowest business impact.

How to Conduct Sourcing?

The supplier you choose can positively or negatively affect your business’ reputation, so consider that your supplier is a business partner. You need to trust that supplier and rely on them as they substantially impact your business. That said, there are specific characteristics that you should be looking at, and these are:

- How long the supplier has been in business and their experience

- The supplier’s ability to negotiate prices

- The supplier’s adaptability when changing order quantities and delivery time frames

- Delivery times

- Range of available products and/or services

- Traceable customer reviews

- Accommodating customer service

- Financial stability

The next step after selecting the supplier is to research and secure an agreement. This means meeting suppliers face to face for price negotiations. It is essential to strike a deal that benefits both sides with strategic sourcing. Discussions concerning turnaround time, payment terms, cancellation terms, and minimum order quantities are crucial.

Next, your vendor contract must cover the following elements:

- Description of the products or services the supplier agrees to provide

- The standard of quality of the goods or services should be

- Duration of the contract term

- Payment terms

- Indemnity, should there be loss arising from negligence

- Repercussions should there be a breach of contract

Determination of payment terms is a must as this can affect the cash flow of both businesses. The ability to guarantee payment with shorter time periods ensures that you get deal points. Additionally, delivery times and locations must be expressly agreed upon as miscommunications and delays can cause costly disruptions.

Remember to choose the supplier who has a delivery model that works for you. You can select the Continuous Replenishment Model, where the supplier makes deliveries according to a predetermined agreement and schedule.

Alternatively, you can pick the Just In Time Delivery Model, where the company receives supplies as needed. Lastly, the On-Demand Delivery Model is where the supplier delivers goods when requested or demanded by the customer.

What Is Tactical & Strategic Sourcing & What Are the Differences?

Strategic sourcing differs from tactical sourcing as tactical sourcing aims to achieve the lowest possible cost without considering other factors like:

- Supplier relationship management

- Supply chain risk mitigation

- Public perception of supplier

- Materials used in products

- Personal use for services

Strategic sourcing is primarily focused on the comprehensive and long-term system of sourcing. It is used to help meet current and long-term business objectives.

As discussed before, the main goals of strategic sourcing are:

- Cost-cutting and reduction of risk

- Market research

- Management of supplier relations

On the other hand, tactical sourcing is short-term-focused and very hands-on. It is characterized by fast requisitions, quotations, and order processes to ensure a quick turnaround, high quality, and the lowest price possible.

Small businesses, manufacturing companies, and older companies favor tactical sourcing. The primary benefit of using tactical sourcing is that it is not as complex as strategic sourcing. However, one drawback is that market research is limited, and vendor relationships are not developed. Your business may miss out on negotiation opportunities, partnerships, and process improvements.

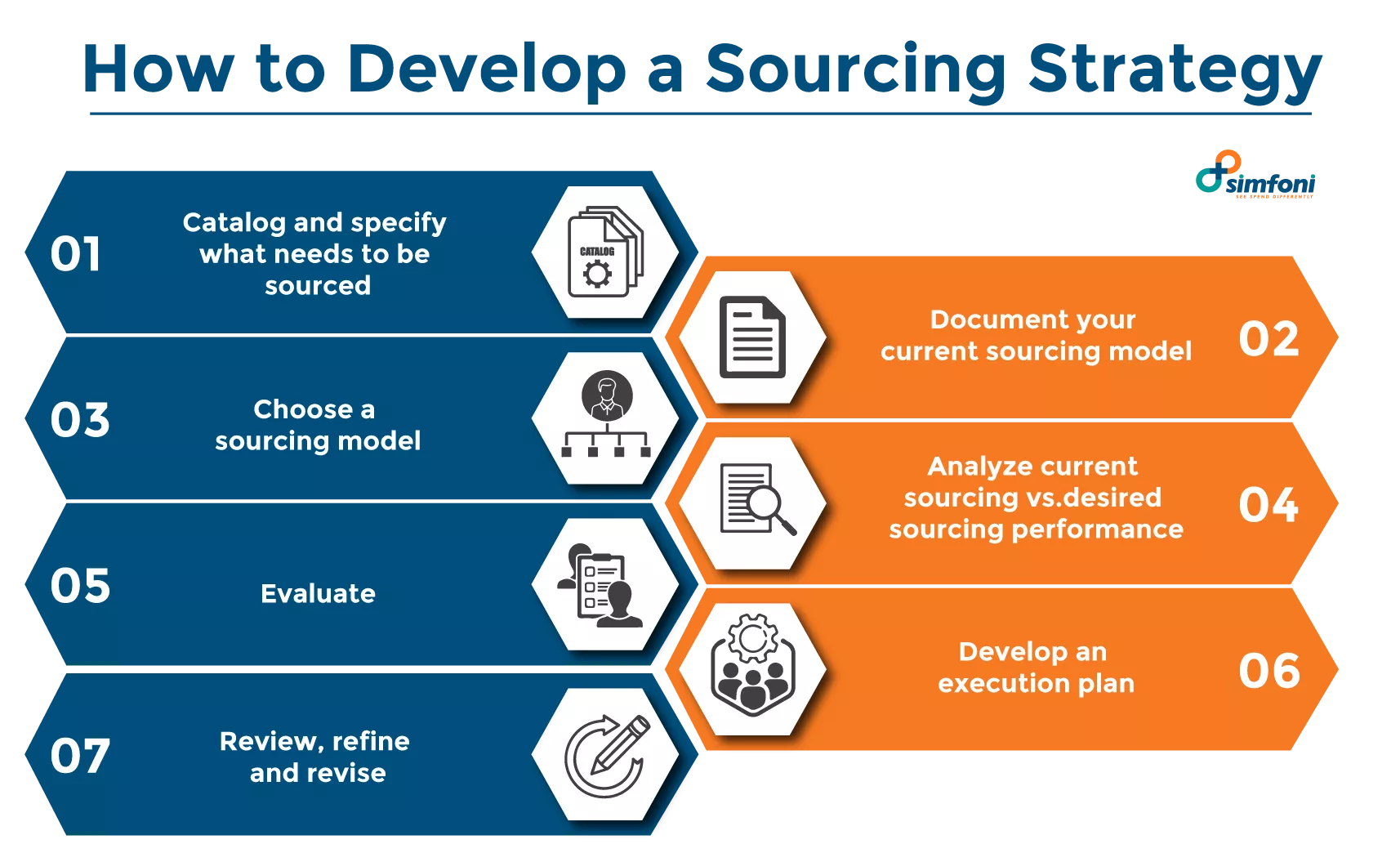

How to Develop a Sourcing Strategy?

So, how do you practically source quality suppliers? The first step always starts with creating a solid sourcing strategy.

Generally, procurement teams need a long-term sourcing strategy that details how the business will establish and uphold the continuous flow of the targeted goods and services to your company’s supply process. Additionally, the strategy must address how you will edge out the competition looking for the same goods and services.

But is there really a need for a sourcing strategy? The answer is yes! So, how do you get started?

Here are the steps to writing a sourcing strategy

1. Catalog and specify what needs to be sourced

Sourcing teams need to write up a list of the resources, goods, services, raw materials, and functions that should be included in your sourcing strategy. Make sure to consider both present and future needs.

2. Document your current sourcing model

This step involves thoroughly analyzing who currently supplies goods or the service to you. Take note of whether the supplier performed well and how your relationship has been. Proceed to review how much you are currently spending and what value you derive from that supplier.

3. Choose a sourcing model.

From your list in step 1, determine on a scale of 1 to 10 how important your desired goods and services are to your business. Categorize them into critical or non-critical and decide whether or not they support your flagship product or are in service of some add-on product. This should help you pick a suitable sourcing model for your organization.

4. Analyze current sourcing vs.desired sourcing performance

Analyze the performance of your current sourcing model vs. your desired sourcing model. You now need to review how well your current sourcing methods are meeting your goals and if they meet your desired sourcing goal presently and long term.

5. Evaluate

This step involves analyzing which supplier has the closest alignment between your current sourcing method and the desired method of sourcing, according to your strategy.

6. Develop an execution plan

Having identified the changes you would want to make to your sourcing process to match it with your desired strategy, it is now time to draw up an action plan and develop a roadmap for implementing those changes.

Some steps you could include in the roadmap are:

- Recruiting staff with relevant knowledge and expertise

- Looking for and evaluating new vendors

- Rethinking your relationship with the vendor

- Developing your team in areas you want to invest in or innovate

- Phasing out any products or services that no longer add value

- Improving on or working on your competitive advantage in your field as an organization

7. Review, refine and revise.

This stage involves continuous data analysis to ensure that your sourcing process is as efficient as possible. This data analysis can help you determine if any areas need further improvement to ensure that your supply chain is profitable, competitive, and resilient.

Improving Sourcing Effectiveness

Let’s now take a look at how organizations can improve the effectiveness of their sourcing process. Generally, there are 10 key aspects that you should consider when aiming to improve the relationship with suppliers and create long-term success for all parties involved. These aspects are as follows:

- Approach sourcing as an ongoing process and not a final destination

- Develop contracts that benefit both parties.

- Identify all costs and their impact on risk and price

- Understand that the greater the bilateral dependencies, the greater the need for preserving continuity

- Ensure that the contract is a flexible framework, not a legal weapon

- Develop safeguards to prevent defection

- Minimize transaction costs with shared visions and predicted alignments

- Be credible

- Build trust

- Keep it simple

Sourcing and Procurement Trends

Conducting business in the current digital space requires a data-centric approach to sourcing and procurement. The current trends in sourcing and procurement are as follows:

1. Emphasis on Risk Management and Flexibility

The pandemic highlighted the importance of adaptability in business and supply chain operations. As a result, resilience and adaptability of supply chains became one of the top priorities for organizations.

Procurement specialists aim to thoughtfully evaluate and manage supply chain risks and design better contingency plans, such as establishing relations with backup suppliers and optimizing inventory.

Additionally, digital transformation and migration to cloud-based software solutions will allow organizations to improve supply chain management, become more agile and mitigate risks more effectively.

2. Sustainable Procurement

The consequences of pollution and global warming have become impossible to ignore; organizations are more likely to begin taking a sustainable procurement approach. Sustainable procurement includes consideration of local sourcing, selection of suppliers who also align with sustainability values, and switching from linear to circular supply chains to reduce waste and add to cost savings.

So, what is the future of sourcing in the post-Covid era?

Over the next decade, sourcing and procurement are likely to become an extensive part of most businesses. Experts hope that this will increase transparency, support the need for better risk avoidance, and guide companies through some of their biggest challenges.

Let’s dive into some of these challenges and see how they might shape the future of these two processes.

1. Risk Avoidance

The expectation is that procurement will start to move away from a narrow emphasis on compliance and begin to take on a more comprehensive perspective. Such a broad approach will force organizations to evaluate total risk exposure, risk transfer pricing, and investment in demonstrable risk mitigation.

To achieve these objectives, companies will have to rethink their strategies for supplier risk management. In fact, it will be necessary to adopt new metrics to streamline major sourcing and supply decisions. In turn, waste minimization and maximizing purchase value will be achieved.

2. Sustainability

Avoid underestimating the impact of a rapidly changing market. In today’s business environment, millennials are a purchasing powerhouse. So, procurement functions will have to design supply chains that satisfy this customer base.

This process will likely involve strategies beyond basic cost-cutting measures as younger buyers are less fixated on price than previous generations and are more likely to prioritize sustainability and CSR over knockdown deals.

3. Globalization

Over the next few years, emerging markets will transform the supply and demand trends upon which we have come to depend. Hot spots to watch are China and South America, both of which are developing rapidly.

Experts are predicting that big businesses will start to construct expertise in this region and countries like Russia and India. There may be a need to hire remote “on location” managers across several emerging nations.

Conclusion: Simfoni’s eSourcing Solution

An excellent and strategic sourcing process is essential to the success of any business. Still, more than that, the implementation of automation in the sourcing process will bring immense benefits.

Simfoni’s eSourcing solution removes the inefficient, labor-intensive processes of traditional sourcing and replaces them with a unique combination of powerful, AI-backed technology and experienced sourcing professionals.

Say goodbye to problematic guesswork and manual spreadsheet analysis, time-consuming drilling through numerous spend and operations categories, or countless contract comparisons. Simfoni makes it easy to improve spend management at the source.

As a cloud-based platform, Simfoni delivers a future-proofed, right-sizing spend management solution that puts you in control of your spend from the start. With our composable architecture, Simfoni lets you mix, match, and create your perfect platform using a wide array of sourcing and spend management modules and tools.

Run RFx events and combine them with any of Simfoni’s seamlessly integrated eAuction, auto-scoring, dynamic bidding, or decision support tools, all to manage, enhance and meet your organization’s unique sourcing and business goals. What’s more, Simfoni gets you up & running fast and will scale to meet your exact needs.

By automating your sourcing process, you ensure your business’s success.

Frequently Asked Question (FAQ)

What are three types of sourcing?

There are three primary types of sourcing:

- Direct Sourcing: Involves procuring goods or services directly from manufacturers or primary suppliers. It often applies to raw materials and specialized products.

- Indirect Sourcing: Focuses on non-production-related procurement, such as office supplies, IT services, or maintenance contracts. These goods and services do not contribute to end product.

- Single Sourcing: Occurs when a company relies on a single supplier for a particular product or component. This strategy can lead to cost savings but may pose risks if the supplier encounters issues.

What are the 5 steps of sourcing?

The five steps of sourcing typically include:

- Identify Needs: Determine what goods or services are required and create a detailed specification.

- Supplier Identification: Research and identify potential suppliers or sources.

- Request for Proposal (RFP) or Quotation (RFQ): Solicit bids or quotations from suppliers, providing them with your requirements.

- Evaluate Offers: Analyze supplier proposals, considering factors like cost, quality, delivery, and terms.

- Supplier Selection: Choose the supplier(s) that best meet your criteria and negotiate contracts or agreements.

What is called sourcing?

Sourcing refers to the process of identifying, evaluating, and selecting suppliers or sources for goods and services required by a company or organization. It encompasses activities such as supplier identification, negotiation, procurement, and contract management.

What is sourcing with an example?

Sourcing, with an example, can be illustrated as follows:

Example: A smartphone manufacturer sourcing components like microchips and screens from various suppliers worldwide. The company identifies reputable suppliers, negotiates contracts, and procures these components to assemble its smartphones. Effective sourcing ensures that the manufacturer gets the best quality components at competitive prices, contributing to the overall success of its products.

What are the methods of sourcing?

Various methods of sourcing include:

- Supplier Database: Using internal databases or external directories to identify potential suppliers.

- Tendering: Issuing tenders or RFQs to invite bids from suppliers.

- Online Marketplaces: Utilizing online platforms to connect with suppliers globally.

- Networking: Building relationships with industry contacts to discover potential sources.

- Agent or Broker: Employing intermediaries to identify suitable suppliers.

- Reverse Auctions: Conducting online auctions where suppliers compete to offer the lowest price.

What is the role of sourcing?

The role of sourcing is to:

- Identify Suppliers: Locate potential suppliers or sources for goods and services.

- Negotiate Contracts: Negotiate terms, prices, and agreements with suppliers.

- Procurement: Facilitate the purchase of goods or services from selected suppliers.

- Cost Management: Manage costs and ensure cost-effective sourcing strategies.

- Supplier Relationship: Develop and maintain positive relationships with suppliers.

- Risk Management: Evaluate and mitigate risks associated with sourcing activities.

What are sourcing rules?

Sourcing rules are guidelines or policies that organizations establish to govern their procurement and supplier selection processes. These rules define the criteria for selecting suppliers, sourcing regions, and sourcing strategies. They help ensure consistency and compliance with procurement objectives and requirements.

What is the formula for sourcing?

The formula for sourcing can vary based on specific objectives and metrics. However, a basic formula for calculating sourcing effectiveness is:

Sourcing Effectiveness = (Total Value Sourced / Total Potential Value) x 100

This formula measures the percentage of potential procurement value that an organization has successfully sourced or procured.

What is the KPI for sourcing?

Key Performance Indicators (KPIs) for sourcing may include:

- Cost Savings: Measures the cost reduction achieved through sourcing activities.

- Supplier Performance: Evaluates the performance of selected suppliers in terms of quality, delivery, and responsiveness.

- Lead Time: Measures the time it takes to source and procure goods or services.

- Supplier Diversity: Evaluates the diversity of the supplier base, promoting inclusion and reducing risk.

- Sourcing Cycle Time: Measures the time taken to complete the entire sourcing process, from identification to contract finalization.

What is a six sourcing strategy?

The Six Sourcing Strategies are a set of approaches used to optimize sourcing decisions:

- Single Sourcing: Relying on a single supplier for a specific item or component. Often used for cost savings but carries risks.

- Dual Sourcing: Utilizing two suppliers for the same item to ensure redundancy and mitigate risks.

- Multi-Sourcing: Engaging multiple suppliers for an item to diversify risk and maintain competitive pricing.

- Global Sourcing: Sourcing goods or services from international suppliers to access cost advantages or specialized expertise.

- Outsourcing: Transferring specific business functions or processes to external suppliers or service providers.

- Insourcing: Bringing previously outsourced functions or processes back in-house for greater control or cost-effectiveness.

What are the four pillars of strategic sourcing?

The four pillars of strategic sourcing are:

- Spend Analysis: Analyzing spending patterns and identifying opportunities for cost reduction and process improvement.

- Supplier Evaluation: Assessing suppliers based on criteria such as performance, reliability, and ethical practices.

- Supplier Relationship Management (SRM): Developing and nurturing positive, collaborative relationships with key suppliers.

- Contract Management: Creating and managing contracts that align with sourcing objectives and protect the interests of both parties.

What are the three main elements of a sourcing plan?

A sourcing plan typically consists of three main elements:

- Sourcing Objectives: Clearly defined goals and objectives for the sourcing initiative.

- Sourcing Strategy: The approach and methodology to be used for supplier identification, selection, and negotiation.

- Sourcing Timeline: A timeline outlining key milestones and deadlines for each phase of the sourcing process.

What is the role of a sourcing manager?

The role of a sourcing manager involves:

- Supplier Selection: Identifying and evaluating potential suppliers.

- Negotiation: Negotiating favorable terms and agreements with suppliers.

- Cost Management: Managing procurement costs and seeking cost-saving opportunities.

- Risk Assessment: Identifying and mitigating risks associated with sourcing.

- Contract Management: Creating, monitoring, and enforcing supplier contracts.

- Supplier Relationship: Building and maintaining positive relationships with suppliers to ensure reliability and collaboration.

How can organizations adapt their sourcing strategies to address changing market conditions or disruptions?

To adapt to changing market conditions or disruptions, organizations can:

- Diversify Suppliers: Explore additional suppliers or sources to reduce reliance on a single source.

- Scenario Planning: Develop contingency plans for various scenarios and potential disruptions.

- Risk Assessment: Continuously monitor and assess supplier risks, adjusting sourcing strategies accordingly.

- Digital Solutions: Leverage digital tools and platforms for real-time market insights and supplier collaboration.

What are common challenges in global sourcing. How can organizations overcome these?

Common challenges in global sourcing include many things. For example, language barriers, cultural differences, logistical complexities and regulatory compliance. To overcome these challenges organizations can do these things:

- Cross-Cultural Training: Provide training to staff involved in global sourcing to understand and navigate cultural differences.

- Local Partnerships: Establish partnerships with local experts or intermediaries in foreign markets.

- Compliance Expertise: Invest in compliance expertise to navigate international regulations and trade agreements.

- Supply Chain Visibility: Implement supply chain visibility tools to track and manage goods across borders efficiently.

Useful Resources

- Cost Reduction Strategies in Procurement.

- Effective Procure-to-Pay Process Guide (P2P Procurement).

- Guide to eProcurement software & Solutions.

- Guide to Manage Tail Spend and Improve the Bottom Line.

- Guide to Procurement Software & eProcurement Solution.

- Guide to Understanding Category Management in Procurement.

- Leveraging AI & Machine Learning in Procurement.

- Procurement Analytics & Implementation.

- Procurement Management - Key Steps and Roles.

- Procurement Marketplace - Reinventing Procurement

- Savings Tracking Process in Procurement.

- Source to Pay Process, Steps & Definition.

- Spend Analysis in Procurement: Importance, Process & Examples.

- Supplier Diversity in Procurement

- Sustainable Procurement - Importance & Best Practices

- Understanding the What, Why, & How of Strategic Sourcing.

- Procurement Auctions – How It Works, Example, and Risks.

- Supply Chain Management (SCM): How It Works and Why It Is Important

- What is Contract Management - Everything You Need to Know

- B2B Marketplace - The Ultimate Guide to Procurement Marketplace

- Spend Management - Importance & Best Practices On Business Spend Management Software & Solutions

- Strategic Sourcing – Ultimate Guide To Strategic Sourcing Processes

- Spend Cube – Ultimate Guide to Spend Cube Analysis

- Procurement Software - Automate Your Procurement Process