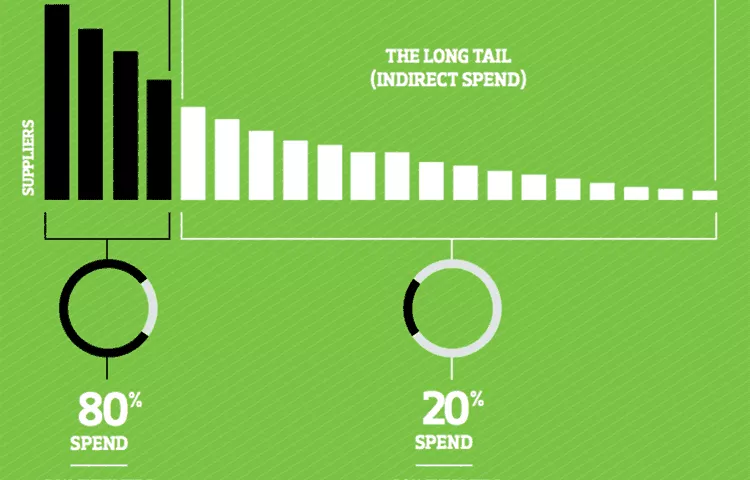

In the world of strategic sourcing, realizing 5 to 8% savings is considered to be impressive. After all, these are the high-spend categories and are supposedly already well-managed and frequently revisited for improvement opportunities.

In contrast, when our clients work with Simfoni on tail spend management or low-value spend engagements, we witness savings that can easily exceed 20% from time to time. This article explains how — with the right combination of subject matter expertise, leverage and technology — such savings are achievable.

In the world of tail spend, we typically pursue the following sourcing levers: Demand Challenge, Specification Alignment, Volume Leverage, Competitive Bidding, Alternate Solutions, Supply Chain Optimization.

I’ll explain each lever by way of providing an example for each one that also illustrates how savings can be achieved in excess of 20%:

Demand Challenge — perhaps the simplest and most neglected lever of all … the avoidance of buying something by definition generates a 100% saving. Imagine identifying that a particular item was in stock and therefore a replacement was not required. I have lost count of the number of times that I have seen customers order laptops with laptop bags. But not all users desire the laptop bag, and most IT departments have a cupboard full of them. But the same rule applies to factory spares that are not linked up. Despite being an internal investigation, making such enquiries is surprisingly more effort than simply buying new, and hence is often overlooked; but with smart analytics that cross-reference inventory systems with procurement requisitions such savings can be more easily found.

Read More: – What is Source to Pay – A Guide to Source to Pay (S2P) Process

A lost art in the modern world is the concept of repairing stuff. But, if one is inclined to look around, a surprising number of items can be repaired very cost effectively, and while the repair costs reduce the savings, the overall savings can still be well over 50%.

And my favorite example of demand challenge lies in software licensing. As we move more and more to cloud-based applications paid for by p-card, the propensity to oversee the charges wanes significantly. Organizations are rife with user licenses for people who have left the company and premium subscription services that are not required by the user.

Specification Alignment — This is probably the most frequent technique that we deploy on tail spend management engagements. It is quite surprising (or maybe not!) how often the end user is not an expert in the product that they are procuring. IT heads who are not up to date with the latest hardware options, Event Managers who don’t know the price differentials between various display equipment. And changes in specification are significant. We recently had a customer situation where the requirement was for daily disposable gloves (5,000 of them, every working day). In this case we found a higher quality glove that cost 50% more, but lasted for the whole week — and was more comfortable for the workers. That resulted in a 70% saving on glove spend. Having a buying-desk with a team of buyers who are specialist in their particular category of spend ensures that the goods and services purchased are fit for purpose, not over-specified and not under-specified — which also has other adverse cost implications.

Read More:- What is Procure to Pay – A Guide to Procure-to-Pay (P2P) Process

Volume Leverage — This lever is the most well understood. Obviously combining spend, especially in the low-value segment — where volumes are already low — creates greater purchasing power and lower prices. It’s relevant for all standard, repeatable spends such as office equipment, factory consumables, electrical components, lighting, signage, etc. And savings can be 15 to 30% against other direct sales or catalog options, and much more when compared with “across the street” retailers.

Competitive Bidding — We all understand that the more the competition there is, the keener the pricing will be. An effective tail spend management strategy ensures that more of the requirement, even at lower values, gets competitively tendered and results in greater savings.

On this note, it’s worth pausing for a moment and exploring the “minimum 3 bids” heuristic. Many organizations apply this rule and feel safe in the knowledge that the best bid out of three must be “somewhat” competitive and any user bias or preference has been market-tested.

Both assumptions are wrong.

First, it is by no means the case that any of the three bidders are competitive. Consider organizing a hospitality event; if you only invited bids from the local five-star hotels then you haven’t fully explored an entire segment of options in the market from alternative venues (golf clubs, town halls, etc.) or lower grade hotels. And a requirement such as “must have sea-view” is likely to prejudice the shortlist against certain criteria that may not accurately reflect the true requirement. Some end users are expert in ensuring they get the service they require by sourcing an additional two “dummy bids” that are clearly not comparable to the one they really want. The use of a third party, for spends of a certain materiality, can be very helpful in avoiding both of the challenges laid out above.

Alternate Solutions — They are really growing in frequency of adoption. We use the term mostly to describe where the solution can be procured in a different manner, often as a result of emerging technology enablement. A simple example is switching from water bottles to a water fountain. But more exciting examples include switching from using a gas station for fuelling the fleet to engaging a mobile dispenser that comes to the depot and fuels all the vehicles before the shift starts, thereby saving time (going to and waiting at the gas station) and vehicle costs in getting to the station. And removes the potential risk of skimming. Another example is the use of smart bins that tell you when they are getting full so one doesn’t waste time cleaning them out unnecessarily. In the example of the bins, visits were reduced by 40% across the board, although they were actually increased in some locations too resulting in improved customer satisfaction. There are really many situations that are easily costed out and implemented by a team that has the specialist expertise in knows what to look for.

Supply Chain Optimization — We see this a lot in companies that experienced rapid growth; either organically or through acquisition. In short, the organization has outgrown the point at which it enters the supply market for a particular product or service — especially on the services side. We have clients where various departments rent equipment, such a boom lifters, but are not aware that there aggregate demand for such equipment now makes it more cost effective to buy a few of their own. Many offices have printers that eat expensive toner cartridges and are not aware of the stage of deployment when it makes more sense to switch to a service contract for a central MFD (multi-function device). When they make the switch, the savings are usually in the 40 to 50% range — not to count the improved usage of electronic documents, removing the demand for printed documents altogether! Another customer recently switched from buying lubricant by the gallon to installing a dispensing system that not only allows them to acquire lubricant in bulk at 30% cheaper prices, but also reduces packaging waste, reduces the number of order transactions, reduces the incidence of stockouts, reduces spillage — and we managed to get the vendor to pay for the installation as well.

Once you get into the details, it is easy to see that savings of well over 15 to 20% can be achieved in tail spend management, provided you have the right combination of subject matter expertise, appreciation of the vendor environment and volume leverage — all of which Simfoni has garnered by specializing specifically in the provision of a tail spend management platform.