PROCUREMENT MANAGEMENT

Comprehensive Guide to Procurement Management by Simfoni’s Procurement Professionals

Table of Contents

Introduction to Procurement Management

Procurement Management ensures that all materials, products, goods, and services are properly acquired so that projects and processes can proceed efficiently and successfully to positively impact the bottom line and strategic business operations.

Simfoni.com Tweet

The word procurement implies a simple transaction involving a buyer and seller. However, the process of acquiring goods and services tends to be complex and requires execution on several platforms.

With procurement management, organizations can reduce their costs and boost productivity. It also provides access to crucial vendor and product information and ensures transparency of the initial purchase request process right through payment.

However, to get the best outcome out of your procurement management process, implementing technology is good business practice. Keep in mind though that procurement activities are not a one-time process; instead, they require continuous monitoring. So if you’re wondering how to get around procurement management basics, this guide is for you.

What is Procurement Management?

So what is procurement management?

We define procurement management as a process responsible for overseeing and administering all the methods involved in acquiring materials, products, goods, and services needed for efficient operations.

It involves multiple stakeholders and departments such as commercial, legal, technical, and managerial parties. As a business, your procurement team must carefully balance the needs of all departments. Proper procurement management can reduce lapses in communication and ensure organizational success.

It also helps to manage external vendor relationships and ensures compliance with contract terms and regulations. Additionally, procurement management allows businesses to meet project goals, negotiate contracts effectively and manage supply chain logistics.

The terms “sourcing,” “purchasing,” and “procurement” are at times used interchangeably (depending on the industry) to define the process of procuring supplies. However, sourcing is more strategic, while purchasing and procurement refer to the actual operational function.

Across all industries, organizations depend on procurement management to manage costs. This has a direct impact on an organization’s bottom line as well as strategic business operations. One of the best ways to do this is to use a procurement management system like Simfoni.

Read More:- What is Procurement

What is the Importance of Procurement?

We’ve already touched on how vital procurement management is but let’s dive a little deeper.

It would be challenging for most business operations to run efficiently and successfully without procurement. But procurement is more than just a business necessity. If used correctly, it can give businesses a competitive advantage by driving down costs, avoiding errors and delays, and maximizing resources.

Other reasons why organizations need to take procurement management seriously are:

- It assists in negotiating lucrative production and supplier contracts.

- It spearheads innovative new processes and plays an essential role in expanding business operations.

- It spearheads corporate social responsibility and diversity by proactively partnering with diverse suppliers.

Benefits of Procurement Management

A well-executed procurement management process has several benefits. It helps improve certainty and quality, controls costs, and reduces overall risk. Let’s discuss these benefits in detail:

- Increased certainty and quality: Procurement management helps with planning and negotiating detailed contracts. This increases certainty about the quality of procured services and products and helps improve stakeholder confidence.

- Cost control: Cost control is the number one concern in all companies. Procurement management assists in carefully managing costs by negotiating procurement pricing and controlling other procurement-related costs. This ensures that the company stays within budget regardless of the project.

- Reduced risk: If an organization has clarity about its vendors, contract terms, and product and service quality, this reduces any potential procurement risks.

Suppose you want to keep your procurement process on track. In that case, it’s essential to have a thoroughly developed and competent procurement management process.

How Does Procurement Management Work?

A procurement management process has to be guided by a strong procurement strategy that aligns with the organization’s business goals.

This strategy provides your procurement team with a method of obtaining goods or services from external suppliers in a cost-effective manner. Having solid vendor relationships is crucial to ensuring that the procurement process runs smoothly and on budget.

Procurement teams are in charge of overseeing this entire process. They are responsible for:

- Finding suppliers

- Tracking orders

- Diversifying suppliers

- Defining contract terms and costs

- Diversifying

- Creating a list of approved vendors for future needs

- Ensuring that all parties fulfill their obligations

Functions of Procurement Management

So what is the function of procurement management in a business?

In most organizations, procurement management handles all procurement transactions and any associated data streams. It encompasses vendor management which includes identifying, screening, sourcing, and negotiating contracts with suppliers.

Additionally, procurement management facilitates the business in enforcing a purchasing strategy that ensures that all the procurement practices align with the needs of all internal stakeholders and with the overall business strategies.

Generally, procurement management is composed of five functions which include:

1. A Purchase Requisition

This document (created within the company) is a request to purchase a good or service. It can be either direct or indirect spending, depending on the needs of that particular project. This document is then sent to the procurement department.

2. Purchase order (PO)

The procurement department sends the vendor the purchase document that details each order’s goods or services and quantities to be bought and delivered. Each PO will include a tracking number, a description of the items ordered, and the relevant quantities.

3. Invoice Approval

Once the PO is approved, the following process includes reviewing and approving vendor invoices before paying them. Each invoice has to be sorted and then sent to the appropriate stakeholder for approval. Many businesses use ERP systems to log these approvals.

4. Vendor Management

Another function of procurement management is to identify suppliers, monitor and track vendor performance, obtain quotes, negotiate contracts, timelines, and make payments. This process is fundamental in organizations with a complicated procurement process and cannot afford delays due to tight deadlines.

5. Contract Management

The last function of procurement management is to administer and monitor contracts. This process oversees the administration of vendor agreements, from the drafting of the contract to its execution. The aim is to ensure that all vendors meet the agreed requirements and that any contractual or regulatory risk is mitigated.

Procurement Management Fundamentals

Regardless of your industry, developing good procurement management processes starts with understanding the fundamentals of procurement management. For the most part, procurement follows a series of systems and processes that identify, source, and manage contracts.

An organization has to have sound purchasing management that reduces costs and maximizes a return on investment. But what steps should you take as a procurement manager to achieve this goal?

We’ve identified ten fundamental procurement management factors that will assist in optimizing your purchasing process and save your organization money.

1. Understand your Purchasing Portfolio

Knowing how your purchasing portfolio functions is essential. For example, supply chain management depends on accurate, tangible, and measurable data. So organizations have to have a thorough understanding of the value and nature of their suppliers and purchases. This will form the basis of a sound procurement strategy.

2. Organize your Purchases

Whether you use an MRP, ERP, or any other system to calculate and manage your purchasing, it’s essential that you centralize your data and purchase orders. This will give a complete overview of your portfolio and organize your procurement process according to groups. This process will ensure that you:

- Reduce the number of orders placed, shipping costs and avoid stock shortages

- Can negotiate bigger discounts with suppliers and vendors

- Can increase the amount of business you get from critical suppliers.

3. Control your Inventory

It’s important to realize that procurement management consists of so much more than controlling the cost of purchased goods. You’ll need to factor in warehousing costs. Experts peg these storage costs at anywhere between 20% and 40% of an asset’s value annually. Many options for reducing these costs are at your disposal, including consignment and staggered delivery.

4. Procurement function must be included in product development

Procurement specialists have to be included in the development of all your products right from the beginning. For example, they can give you options of various strategic suppliers who can support product development.

Combining your engineering, supplier, and purchasing processes will develop a product that meets technical requirements and procurement initiatives like cost and time. This also engages your suppliers and makes them responsible for quality and cost control.

5. Risk management and the introduction of performance indicators

Managing your risk from the onset allows you to formulate proper contingency plans that will prevent specific problems like:

- Delivery delays

- Raw material cost fluctuations

- Inconsistent quality

- Single-source products

Additionally, performance indicators that assist in tracking on-time delivery, controlling quality and costs, for example, provide a way to quickly non-compliance by a supplier.

6. Identify what your Customer Needs

Let’s start this point with an example; at Heathrow Airport’s Terminal 5, the airport wanted to purchase rows of check-in desks. On the other hand, the procurement team argued that the real need for the customer was not having enough desks. Instead, people needed a way to pass through the terminal quickly.

The procurement team suggested an alternative solution for the airport (borrowing an idea from the supermarket checkouts systems) to reduce costs and check-in times. Identifying what your customer needs and separating it from what they want is the proper course of action.

7. Look Outside your Market

Taking the Heathrow example, the procurement team was able to deliver an alternative solution outside of the usual answers. Organizations should be able to look outside of their industry for procurement solutions.

8. Manage and Prioritize Relationships

Prioritizing and managing relationships is also a fundamental part of procurement. Businesses should have good contract management skills. This skill helps you control the process and, more importantly, gives you an idea of how well your supply contracts are doing.

Remember that relationships take time, so you’ll need to manage and prioritize your supplier relationships and figure out which relationships are more important to you. Additionally, it’s essential to think about how this might change in the future.

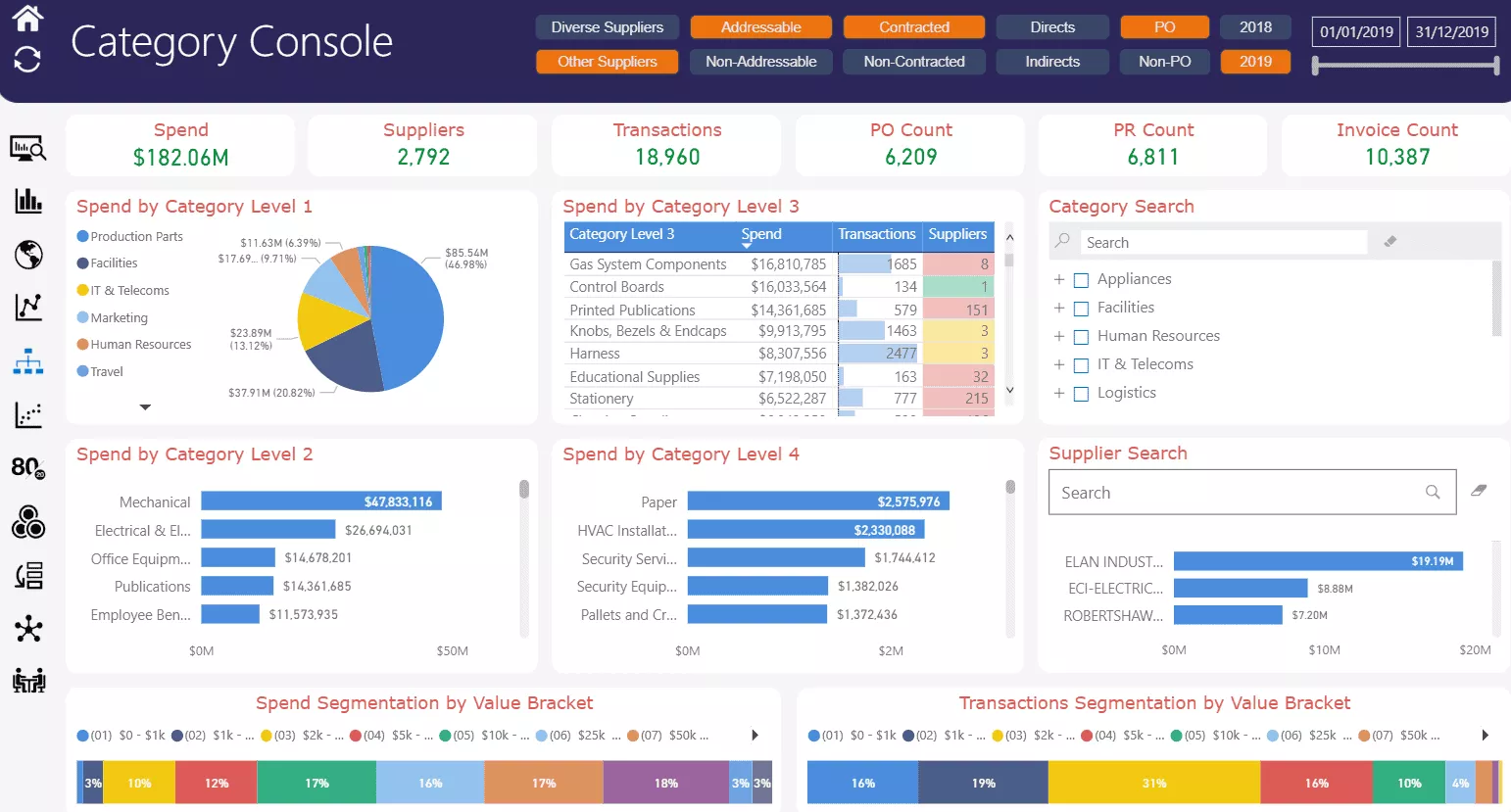

9. Ensure you Collect Spend Data

If you don’t know by now, spend data is possibly the most powerful tool any organization can have for procurement processes. This data helps you know exactly what is going on during each cycle. You’ll know what you’re buying, whom you’re buying from, and the frequency so you can implement any cost-saving measures.

10. Know your Negotiating Position

From the get-go, it’s essential that you have a clear position to be upfront with all your stakeholders. As a business, you should have set boundaries before you even start negotiation with a supplier. This will empower you and make the purchasing process a lot smoother.

Steps Involved in Procurement Management Process

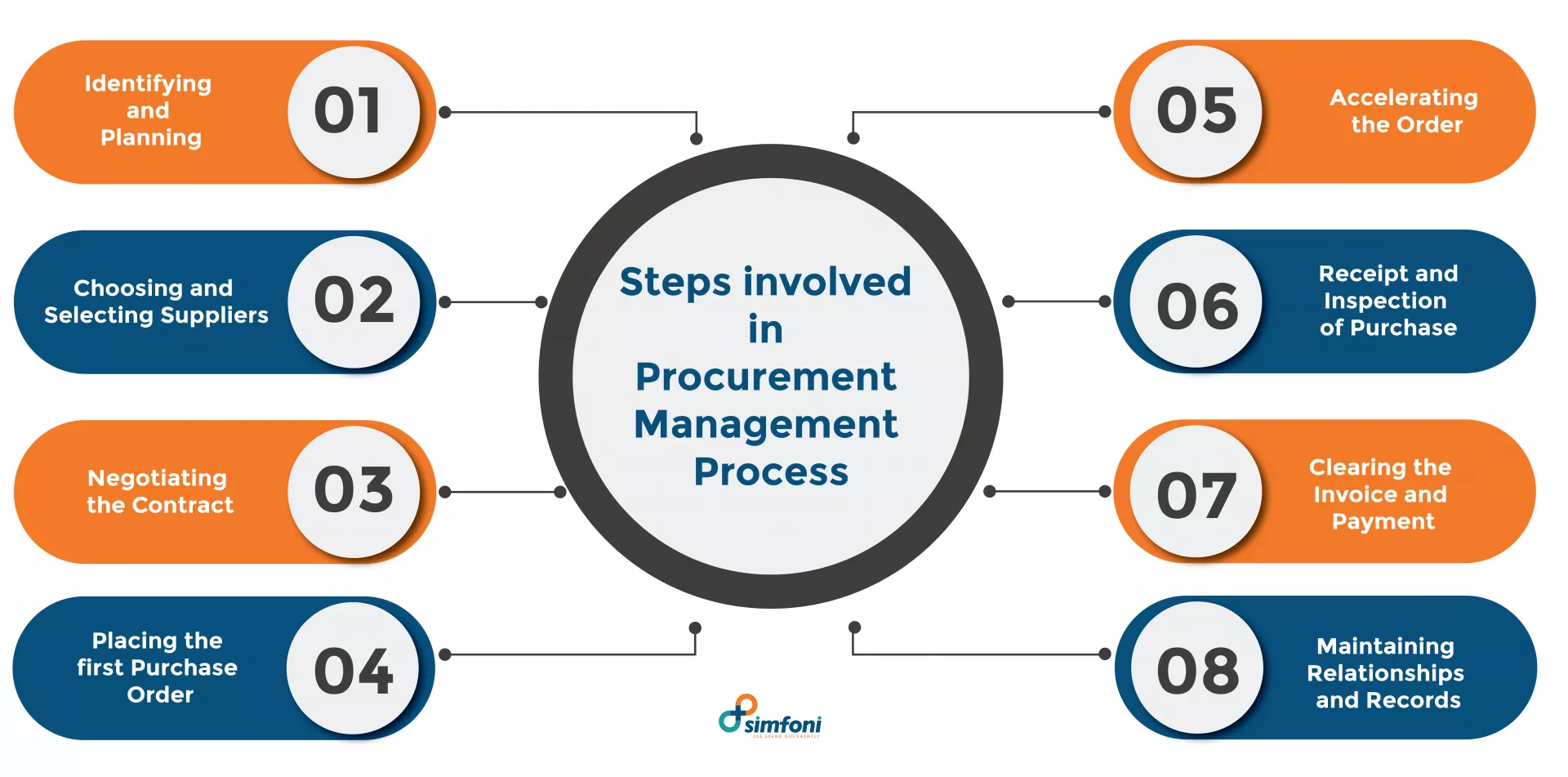

So far, we’ve covered the definition of procurement management, how it works, the benefits, and the fundamentals. However, none of this information will be helpful without having a better understanding of the steps involved in the procurement management process.

Managing goods, services, materials, and products efficiently involves a complete overhaul of the entire procurement lifecycle. While these processes differ depending on the organization’s needs, business goals, and industry, they are generally applicable.

The process that a company goes through when making a purchase typically includes the following steps:

Step 1: Identifying and Planning

This first step involves establishing the product or service need and identifying the specifications for the product itself. Additionally, there needs to be planning or forecasting based on existing projections and data detailing when and how the product is ordered and re-ordered.

Step 2: Choosing and Selecting Suppliers

Selecting a supplier that meets the product needs is the next step. This process involves identifying a supplier from an established relationship with approved vendors, researching new suppliers, and sending out a requisition for information, proposal, or quotation.

Step 3: Negotiating the Contract

Step 3 usually involves negotiating the best price and terms for the product. This is done through competitive bidding by the suppliers who come forward with their quotes. Negotiations then happen, and the company has to communicate requirements and expectations. Once all the terms are agreed upon, the contract is finalized and signed.

Step 4: Placing the first Purchase Order

The purchase order is a document that specifies the exact price, product specifications, terms, and conditions of the product and service being supplied. This document clearly shows all the details of the purchase process.

Step 5: Accelerating the Order

Sometimes, it becomes necessary to expedite a product order. This could be due to a schedule change or a product becoming obsolete earlier than expected. One way to address such issues is to examine how timely deliveries are made during this acceleration process. This can reveal any underlying problems, such as a lack of clarity on delivery times, payment dates, and completion of work.

Step 6: Receipt and Inspection of Purchase

During this process, orders are reviewed and compared to the established product specifications and quality standards. The Purchase order has to match with the invoice and the packing slip or receiving documents.

Suppose the inspection reveals that the delivery does not meet the specified standards. In that case, it’s standard procedure to complete a receiving discrepancy report.

Step 7: Clearing the Invoice and Payment

The next step is to align purchasing and accounts payable so that the process is completed.

Step 8: Maintaining Relationships and Records

Lastly, the last step is to maintain proper records for audit and tax purposes. This process also confirms the product warranty and makes it easier to re-order the product in the future. Most organizations also provide data and feedback to the supplier based on key performance indicators. This helps to identify areas for improvement in the whole process.

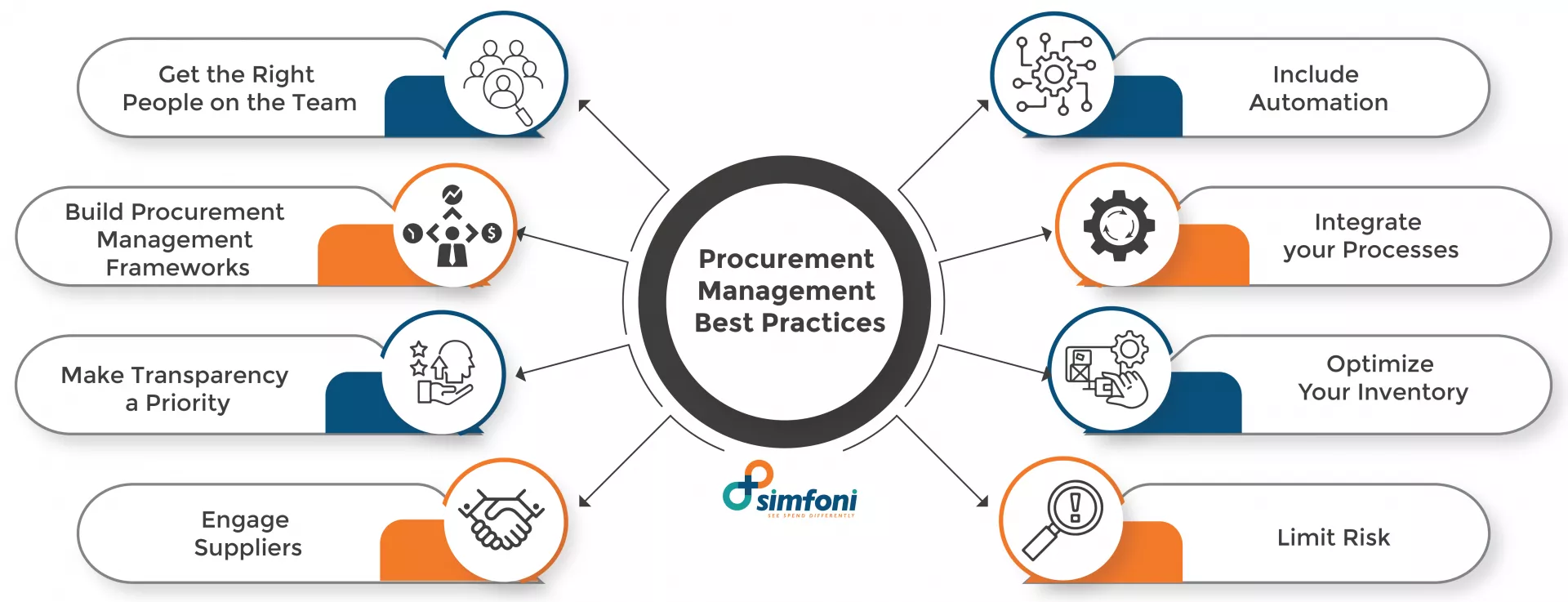

Procurement Management Best Practices

One of the most crucial procurement management practices in 2021 is automation. In addition to implementing the above steps, automation and some of the practices outlined below will help you create a smooth and reliable procurement management process.

If there’s anything you should take away from this article today, it’s the fact that automation goes beyond cost reduction. Yes, the cost of running a business is on the rise, and significant supply chain vulnerabilities are arising.

However, while automation addresses these challenges, the proper way to think about it in the procurement framework is that automation should transform your entire procurement process. Before we begin, keep in mind that these practices need to align with internal policies and procedures.

Get the Right People on the Team

It’s essential that you hire a procurement specialist with enough experience developing and evaluating all procurement processes and documents. Why? Because the procurement process is a complex and dynamic system that has overlapping webs.

So, where do you start? Which procurement system works best for your business? How should you automate? Which methods do you integrate, and where can you make improvements?

All these questions need answers. As a result, most organizations stay with the familiar and continue using inefficient, manual processes (think spreadsheet and paper-invoicing) to handle procurement.

This is where hiring the right people becomes essential. A good procurement team will have the right expertise to manage all these issues.

Build Procurement Management Frameworks

If you notice any inefficiencies in your procurement process, the best thing to do is establish a strong procurement management framework. This allows you to look at how sourcing functions in your organization.

This framework should establish guidelines for:

- Managing vendors and negotiation

- Monitoring and approving purchase requests

- Invoicing and payment

- Record keeping

- Conducting quality assurance

- Hiring new buyers and purchasing agents

- Training employees on products

This is not an overnight process; it is an extensive process.

Make Transparency a Priority

Ensuring open communication and accountability during each stage of the process will help tremendously in making procurement easier to manage. This is done by keeping all information concerning purchases, invoices, and vendors on a single system.

This way, your procurement team has easier access to vital data to avoid late or double payment, keep vendors happy, and take advantage of discounts. So whether its vendor management procedures, contracts, completing a purchase order workflow, or managing accounts payable, document it all electronically.

Engage Suppliers

By now, we must sound like a broken record. Still, your company must build a solid relationship with your suppliers. Selecting a vendor that can deliver what you expect, is willing to be accountable, and is amenable to resolving issues that may arise is vital to the success of your procurement process.

For this, you need to have good insight into who your suppliers are. Preferably, seek vendors that are local with experience in your industry. That way, you can track their performance, evaluate the relationship and engage them in a meaningful way.

Lastly, we recommend securing backup vendors that can step in quickly should your leading supplier fail to deliver. Additionally, keep updating your approved supplier list often so that you’re constantly on the lookout for new contacts and opportunities.

Below are some tips you can utilize to optimize your supplier relationships to secure procurement:

- Always maintain clear, open communication regarding purchase orders and requirements. And have a system in place that ensures all your invoices are delivered.

- Establish expectations early by leveraging market knowledge so you can hold your vendors to the same standard.

- Regularly evaluate vendor performance to see whether the quality of goods and services is good value for its investment.

- Pay suppliers and vendors on time because this, in turn, will make your vendors prioritize your company.

- Be aware of what your competitors are doing.

- Track vendor performance against contracts to ensure that their service is still consistent.

Optimize Your Inventory

One of the most overlooked areas in procurement is the management of stock and intake. While this might seem like a daunting task, keeping your inventory at the proper levels requires careful consideration and planning of quantities.

What this does is minimizes waste while ensuring you always meet customer expectations. Keep in mind that holding inventory for long periods does jeopardize ROI. The cost of taxes, warehouse fees, obsolescence, and insurance add up over time.

There has to be a smooth and regular inventory rotation so that your risk is lowered and you don’t spend unnecessarily. Your procurement management plan should ultimately optimize your inventory.

Include Automation

Technology is here to stay, and there is no need to waste time and resources manually managing your procurement process. Automation of procurement processes will save an organization time and money. Experts estimate that inefficient procurement costs businesses up to $1.5 billion annually.

There are several repetitive tasks that your organization can automate. This will give your procurement team more time on their hands to work on other essential tasks. Below are some critical procurement processes you need to automate:

- Payment reconciliation

- Accounts payable

- Invoicing

Integrate your Processes

In addition to documenting everything, you need to integrate similar processes to eliminate discrepancies. Having conflicting data and information in your procurement management systems will slow down the process and create barriers and gaps between operations.

For example, if we look at tasks such as budget requests, quality checks, and dispatch authorization that need manual action. If these tasks are not integrated, then the whole system is operating independently, creating unnecessary bottlenecks.

Your organization needs to integrate such processes to ensure a smooth system from beginning to end. Bridging the gap between one procurement process and another is crucial.

Limit Risk

Forewarned is forearmed, so before developing a procurement management system, you need to consider all the risks involved. An impact assessment is necessary so that you have all the necessary risk management processes in place.

While it’s impossible to insulate your procurement process against every possible risk, have a plan in place that will set you on a path towards full recovery much quicker should anything bad happen.

Factors that might impact procurement management include:

- Compliance legislation

- Health and safety

- Environmental issues

- Bribery

- Traceability

- Social responsibility

Equip yourself with information concerning all these elements and figure out how you and your team can manage them.

Creating a Procurement Management Plan

As we’ve mentioned before, a procurement management system done the right way has several crucial benefits for an organization’s bottom line. So now the question is, how do you create the right procurement management plan?

Below are some critical components that any good procurement management plan should have.

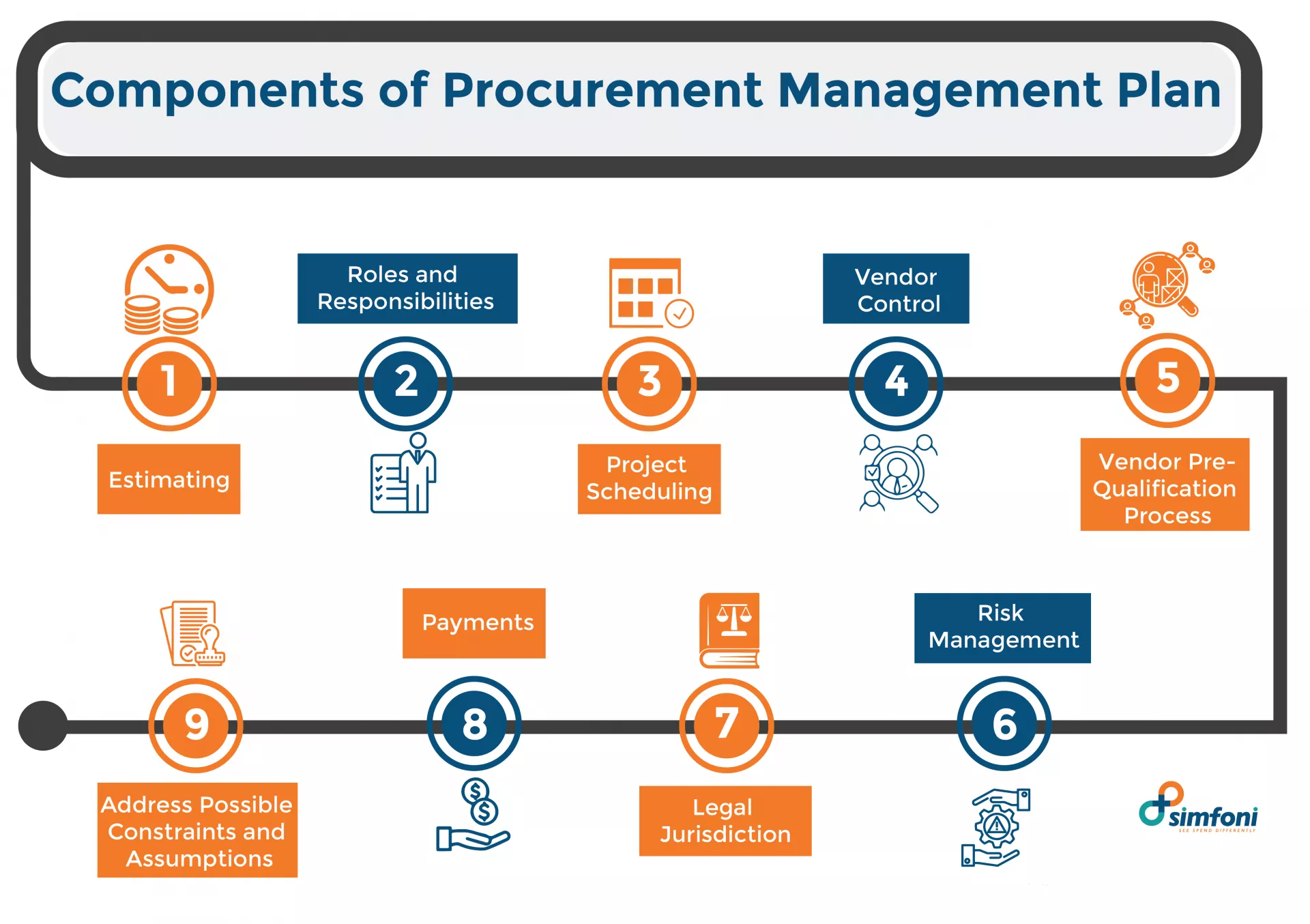

Components of Procurement Management Plan

A procurement management plan details the overall strategy and the management of the process; additionally, it should outline the different sets of requirements laid by all groups of stakeholders.

Overall there are nine main components of a procurement management plan, and they are:

1. Estimating

In most cases, money is vital in every step of the process. So before the bidding even starts, procurement and project management teams all need to produce an estimate of the project’s total cost.

This ensures that there is enough money for all the required procurement activities. During the estimation process, factors like net present value analysis, capital budgeting, cost-benefit analysis should be analyzed and compared for future reference.

2. Roles and Responsibilities

Once the money aspect is sorted out, the next component to discuss is the roles and responsibilities required to manage the procurement process.

A proper procurement management plan needs to define all individual’s roles so that the process runs smoothly. Project managers, in particular, are crucial in overseeing that the organization sticks to budget. They must also manage schedules, contractors, operational managers, lawyers, and contract managers to mitigate any risk.

Identifying roles and responsibilities ensures no overlapping of functions and that everyone understands what they are supposed to do.

3. Project Scheduling

Any significant project will have an array of vendors, contractors, service providers, and suppliers that need to be managed. All these people often affect the project schedule, so they must be well managed.

A project schedule will clearly define each task, including when it starts and when it ends and the budget. The work must be divided, and the project managers need to produce a statement of work (SOW) or terms of reference (TOR) detailing the work requirements for contractors.

These documents provide the base for the pricing of each contractor, and they also help the manager avoid any micromanaging, which can result in complex contractor relationships. Moreover, a project schedule will help identify schedule issues, implications, and constraints that may affect the procurement process.

4. Vendor Control

This is an essential function in the procurement management plant. Often working with vendors means that project managers and their teams surrender control of those portions of the project assigned to the contractors.

However, there needs to be some control in place. This is where vendor control policies become vital to the procurement management plan. The policy ensures that the work of suppliers, service providers, contractors, and more meets the project standards and needs.

Examples of vendor control policies include:

- Site inspections

- Regular project meetings

Both should be included in the procurement management plan and the SOW and TOR documents. Additionally, these policies help manage and set expectations in vendor relationships.

5. Vendor Pre-Qualification Process

Once you have a vendor policy in place, it’s essential to pre-qualify the vendors you want on your team. Include set criteria for the qualifications you desire; this could include vetting processes of past works, project team descriptions, work methodology, and so on.

6. Risk Management

Because you are working with a vast group of people, the element of risk is always high. A good procurement management plan should include a risk profile for each project. It should contain risk level, risk tolerance, level of details, contracts, policies, and reviews.

7. Legal Jurisdiction

A procurement management plan should always establish proper legal jurisdiction. This helps bind all stakeholders to the regulations within the jurisdiction and allows project managers to address the minimum legal requirements of the project and include them in all the contract documents.

Avoiding any legal issues throughout the procurement process should be a top priority.

8. Payments

Payment terms, modes, and methods should always be addressed and defined in a procurement management plant. This avoids any conflicts or issues that may arise in the future.

9. Address Possible Constraints and Assumptions

The plan should always address possible constraints and assumptions that may occur. It can include schedules, environment, standard specifications, quality, security, geographical settings, or ground conditions.

How to Create a Procurement Management Plan

Now that we’ve seen which components are necessary for a procurement management plan, let’s look at some of the steps you need to create one.

Step 1: Outline the Terms

There needs to be an outline of the services and items for procurement in specific terms. This outline should include sizes, the benefits they will provide, the justification, and so on.

Think about it this way. If you need to justify an acquisition, the items need to address whether or not the materials are required for manufacturing goods necessary to complete the project.

At this stage in the procurement management planning, technical information essential to the procurement process must be included. Moreover, there must be sufficient details concerning the date the items are required, based on the need and use dictated by the project timeline. A list of the people who have approved the purchase should be included.

To maximize the process of outlining procurement terms, you can implement the following tips:

- Use templates that allow you to compile the outline quickly.

- Make use of tools with automated approval workflow capabilities. This avoids having to go through a lengthy back and forth approval and purchase process.

Step 2: Determine the Type of Agreement

There are various types of contracts that an organization can enter into with vendors and contractors. To avoid confusion, you need to clearly state the type of contract in the procurement management plan.

The contract should specify all the cost details, including billing rates, material costs, and any applicable or additional fees. Moreover, there should be information about all the contract management details, such as the contract management platform processes that will be used or e-signature requirements.

Step 3: Identify and Mitigate Risks

Risk is always a significant factor, and we’ve mentioned it countless times in this article. So make sure that you have a plan in place that mitigates your risks in procurement. Risk factors could include:

- Shipping delays

- Unrealistic cost expectations

- A contractor’s inability to perform up to standard or meet deadlines

- Vendor conflict

The best way to implement risk factors in your procurement management plan is to have a potential contractor or supplier replacements should anything happen. You can also create a risk register that contains all the risks you’ve identified and mitigation measures you can use to reduce or prevent their impact.

Another way to mitigate risk is to use the right tools to manage your supply chain. For example, Simfoni’s procurement management tool allows you to automate your vendor evaluations and management so that you can track any performance issues. This lowers your overall risk.

Step 4: Cost Determination

The last step is to estimate all the costs involved and write them up in the project in the procurement management plan.

Most of not all procurement processes will involve a request for proposal (RFP) that outlines the procurement needs. The details need to be as straightforward as possible to ensure that the project cost estimation is accurate.

Vendors will then get an invitation to provide bids that include:

- The vendor’s products and or services outline

- How they plan to carry out the job

- Work experience including details of the type of work

- Schedules

- A cost outline

How to Improve Existing Procurement Management

The journey of improving procurement management is never over. There is always a process, system, or way of doing something that will need improvement. However, suppose you’re just starting or transitioning from manual and paper-based processes to full automation. In that case, these are some of the areas you can expect to see changes:

Approvals

Traditional paper-based approvals are annoyingly slow and prone to delays. Think about how long it takes to get all stakeholders and parties involved to print, sign, and transfer physical copies of contracts to each other.

Digital forms, on the other hand, make approvals simpler and faster and by ensuring that all parties can approve and sign remotely.

Invoice Matching

It’s very time-consuming to match invoices to purchase orders and receipts. It requires attention to detail, especially if you’re comparing line items manually.

Automating this process with a digital procurement management software like Simfoni can compare that information with relevant supporting documents in seconds.

Notifications

Paper-based procurement workflows, stakeholders have to wait hours and sometimes days for updates on a contract’s status. Because of this long-drawn-out process, timelines and critical actions can be delayed.

Digital processes, on the other hand, keeps all relevant parties up-to-date with immediate status information.

Integration

Physically creating procurement documents can take days, especially when multiple parties on different teams are involved.

An integrated digital procurement process allows you to create documents, reviews, and approvals in real-time. Integration also fosters collaboration between procurement management stakeholders.

Data Storage

Paper-based record-keeping makes data storage challenging and hinders easy access to information. This stalls the workflow process and not forgetting that physical files take up much space.

Digital storage gives you access to cloud storage, and anyone from anywhere around the globe can easily access the information.

Procurement Management Software & Solutions by Simfoni

So we’ve finally made it to the end, and now you’re wondering which procurement management software should I get?

Before we get there, let’s discuss the key areas that make a good procurement management software. Keep in mind that not all procurement solutions provide the same results, neither are they created equal. So first, you need to determine what you need from your procurement management software before investing in one.

Key areas to look for when comparing procurement management systems include the following:

- Advanced vendor management features that allow you to monitor the performance of suppliers every step of the way. It should also allow you to quickly onboard new vendors.

- An array of workflows and template documents that you can customize. You should be able to go paperless and automate critical components of your procurement management process with speed and efficiency.

- Impressive reporting capabilities allow you to analyze procurement performance and ensure compliance across the procurement management system.

- Several tools that support you in setting and enforcing budgetary controls across the procurement cycle will prevent fraud and costly errors.

Composable Procurement

Watch a video on how Simfoni has fused revolutionary technology with AI-enabled content and deep expertise to automate, streamline and simplify procurement. The result: a composable, on-demand spend management platform that takes the hassle out of procurement.

Conclusion

Benefits of Managing Procurement with Simfoni

Simfoni’s procurement management software is the perfect companion for all your procurement activities.

We understand and believe in Composable Procurement. This new approach to solution design involves selecting the ‘best-of-breed software modules from one vendor. The great news? Our method ensures that the software work together seamlessly with your existing system. So say goodbye to the hassle of connecting your old systems with endless APIs and to buying a monolithic, all-in-one monster.

Take a look at all the options available at Simfoni to maximize the efficiency of your procurement management.

Frequently Asked Question (FAQ)

For your help, we have created a list of answers to assist you more.

What are the 3 main types of procurement?

Procurement encompasses three main types:

1.1. Direct Procurement:

Direct procurement involves acquiring goods, materials, or services that are directly incorporated into a company’s end products. For example, a car manufacturer procures steel, tires, and engines.

1.2. Indirect Procurement:

Indirect procurement focuses on goods and services that are not directly used in the production process but are essential for business operations. Examples include office supplies, IT services, and maintenance.

1.3. Service Procurement:

Service procurement involves the acquisition of services rather than physical goods. It includes hiring consultants, contractors, or outsourcing specific tasks like IT support or marketing services.

What is an example of procurement management?

Let’s take the example of a construction company. They can show how they go about getting materials and services needed for a new building project. This involves steps like finding suppliers for materials like cement and steel, working out contracts, building good relationships with these suppliers, making sure the materials are of top quality and making sure everything gets to the construction site on time.

What are the 4 main roles of procurement?

The four main roles in procurement management are:

Buyer or Purchasing Agent:

Buyers play a key role in the procurement process by identifying suppliers , engaging in contract negotiations and making purchasing decisions aligned with company’s procurement strategy.

Procurement Manager:

Procurement managers oversee the entire procurement process, including strategy development, supplier selection, contract management, and team coordination.

Supplier Relationship Manager:

Supplier relationship managers focus on nurturing and maintaining strong relationships with suppliers to ensure the fulfillment of contracts and optimize supplier performance.

Procurement Analyst:

Procurement analysts use data and analytics to assess spending patterns, identify cost-saving opportunities, and provide insights for procurement decision-making.

What are the main steps of procurement management?

The main steps in procurement management typically include:

Identifying Needs:

Identify the goods or services needed and create a detailed procurement plan.

Supplier Selection:

Identify potential suppliers, evaluate their capabilities, and select the most suitable ones.

Negotiation and Contracting:

Negotiate terms and conditions, create contracts, and ensure legal compliance.

Procurement Execution:

Execute the procurement plan by placing orders, receiving goods or services, and managing supplier relationships.

Monitoring and Control:

Monitor supplier performance, ensure compliance with contracts, and address any issues that arise.

Closure and Evaluation:

Conclude contracts, evaluate procurement outcomes, and document lessons learned for future improvements.

What is the role of procurement?

The role of procurement in an organization is multifaceted:

- Cost Control: Procurement helps manage costs by sourcing goods and services efficiently, negotiating favorable terms, and identifying cost-saving opportunities.

- Supplier Management: It involves evaluating and managing supplier relationships to ensure the timely delivery of quality products and services.

- Risk Management: Procurement assesses and mitigates risks related to supplier reliability, market volatility, and regulatory compliance.

- Strategic Sourcing: Procurement aligns sourcing strategies with overall business objectives to enhance competitiveness and sustainability.

- Compliance: It ensures that all procurement activities adhere to legal and ethical standards.

- Sustainability: Procurement plays a role in sustainable sourcing, considering environmental and social responsibility factors.

What is the concept of procurement?

Procurement is essentially how organizations get stuff they need to run the operations and achieve their goals. It’s a careful and organized process that involves figuring out what you need, picking the right suppliers, hammering out deals, keeping good relationships with those supplier and making sure you get what you need in a smart and cost-effective way all while playing by the rules and being ethical. In short procurement is a crucial function for any organization.

What are the key components of effective procurement management?

Effective procurement management involves several key components, including:

- Strategic Planning: Aligning procurement with business goals and developing a procurement strategy.

- Supplier Selection: Evaluating potential suppliers based on criteria like quality, cost, and reliability.

- Contract Management: Creating and managing contracts that outline terms and conditions, pricing, and performance expectations.

- Risk Assessment: Identifying and mitigating risks related to supplier relationships, market changes, and external factors.

- Compliance: Ensuring adherence to legal, regulatory, and ethical standards throughout the procurement process.

How does technology influence modern procurement management?

Technology has a significant impact on modern procurement management by:

- Automating Tasks: Streamlining procurement processes and reducing manual work.

- Enhancing Data Analysis: Providing insights through data analytics and spend analysis.

- Improving Communication: Facilitating collaboration with suppliers through digital platforms.

- Enhancing Transparency: Offering visibility into the procurement process and supplier performance.

- Enabling E-Procurement: Allowing online procurement, purchase requisitions, and approvals.

What are the challenges of global procurement management?

Global procurement management faces challenges like:

- Cultural Differences: Navigating diverse business cultures when dealing with international suppliers.

- Logistics and Transportation: Managing complex logistics and transportation networks.

- Regulatory Compliance: Ensuring compliance with international trade laws and regulations.

- Currency Fluctuations: Dealing with currency exchange rate risks.

- Supplier Selection: Finding reliable global suppliers and assessing their capabilities.

How does sustainability play a role in modern procurement management?

Sustainability is increasingly important in modern procurement management as organizations seek to:

- Reduce Environmental Impact: Source eco-friendly products and materials.

- Promote Ethical Practices: Ensure suppliers adhere to ethical labor and production standards.

- Enhance Reputation: Showcase commitment to environmental and social responsibility.

- Mitigate Risks: Address risks associated with supply chain disruptions and regulatory changes related to sustainability.

What is the difference between procurement and purchasing?

Procurement involves a full-scale process that covers strategic planning, supplier choices, contract management, risk assessment and more, all aimed at securing goods and services.

Purchasing, on other hand is the practical act of buying goods and services. It is the part of broader procurement process and centers on everyday tasks like placing orders and handling payments.

How does procurement management contribute to an organization's bottom line?

Effective procurement management contributes to an organization’s bottom line by:

- Cost Reduction: Identifying cost-saving opportunities and negotiating favorable terms.

- Efficiency: Streamlining processes, reducing manual work, and minimizing errors.

- Risk Mitigation: Identifying and mitigating supplier-related risks.

- Strategic Sourcing: Aligning procurement strategies with business objectives.

- Supplier Performance: Monitoring and optimizing supplier relationships for quality and reliability.

What are the future trends in procurement management?

Future trends in procurement management include:

- Digitization: Increasing use of digital tools and e-procurement platforms.

- AI and Automation: Integration of AI for data analysis, supplier insights, and automation of tasks.

- Sustainability: A growing emphasis on sustainable sourcing and ethical practices.

- Supply Chain Resilience: Preparing for and mitigating supply chain disruptions.

- Blockchain: Utilizing blockchain for transparency and traceability in the supply chain.

How can organizations measure the effectiveness of their procurement management?

Organizations can measure the effectiveness of their procurement management by:

- Key Performance Indicators (KPIs): Tracking KPIs such as cost savings, supplier performance, and compliance.

- Supplier Surveys: Gathering feedback from suppliers on their experience.

- Spend Analysis: Analyzing spending patterns and identifying cost-saving opportunities.

- Contract Compliance: Monitoring adherence to contract terms and conditions.

- Benchmarking: Comparing procurement performance against industry benchmarks.

How can small businesses optimize their procurement management with limited resources?

Small businesses can optimize procurement management by:

- Strategic Sourcing: Focusing on essential purchases and selecting reliable suppliers.

- Cloud-Based Software: Using cost-effective cloud-based procurement tools.

- Collaboration: Collaborating with suppliers for better terms and discounts.

- Lean Processes: Streamlining procurement processes to reduce manual work.

Training: Providing training to employees involved in procurement to enhance efficiency and compliance.

Useful Resources

- Cost Reduction Strategies in Procurement.

- Effective Procure-to-Pay Process Guide (P2P Procurement).

- Guide to eProcurement software & Solutions.

- Guide to Manage Tail Spend and Improve the Bottom Line.

- Guide to Procurement Software & eProcurement Solution.

- Guide to Understanding Category Management in Procurement.

- Leveraging AI & Machine Learning in Procurement.

- Procurement Analytics & Implementation.

- Procurement Management - Key Steps and Roles.

- Procurement Marketplace - Reinventing Procurement

- Savings Tracking Process in Procurement.

- Source to Pay Process, Steps & Definition.

- Spend Analysis in Procurement: Importance, Process & Examples.

- Supplier Diversity in Procurement

- Sustainable Procurement - Importance & Best Practices

- Understanding the What, Why, & How of Strategic Sourcing.

- Procurement Auctions – How It Works, Example, and Risks.

- Supply Chain Management (SCM): How It Works and Why It Is Important

- What is Contract Management - Everything You Need to Know

- B2B Marketplace - The Ultimate Guide to Procurement Marketplace

- Spend Management - Importance & Best Practices On Business Spend Management Software & Solutions

- Strategic Sourcing – Ultimate Guide To Strategic Sourcing Processes

- Spend Cube – Ultimate Guide to Spend Cube Analysis

- Procurement Software - Automate Your Procurement Process