PROCUREMENT GUIDE

What is Procurement

and How To Optimize Processes, Performance and Technology?

Table of Contents

Introduction to Procurement

Procurement is defined as a strategic process to streamline an organization’s operations to ethically purchase quality goods and services from suppliers to realize business objectives of saving cost, reducing time, and improving profitability.

Simfoni.com Tweet

Simfoni’s Guide To Procurement & Procurement Processes is a detailed article designed to help procurement professionals learn and master the best practices in procurement and to get the most out of their procurement tools. Our Procurement team share their knowledge and experience to help you with procurement, procure-to-pay, and related processes for small, medium, and enterprise businesses. If you’re looking for a better procurement process, this is the place for you!

What is Procurement?

Procurement is the term used when a company needs to obtain goods or services from a third party, such as vendors or suppliers. Procurement should be done in such a way that the goods and sources purchased are of high quality while also keeping costs in mind.

Furthermore, procurement management mandates that businesses seek out vendors who are best suited to their business and its unique requirements. As a result, procurement managers must establish arrangements with the finest suppliers at the best prices to increase corporate profitability.

Procurement is an important aspect of a company’s corporate strategy since it is necessary for a company’s correct functioning and growth, as well as something that many organizations from a range of industry niches require to survive.

Procurement Methodologies

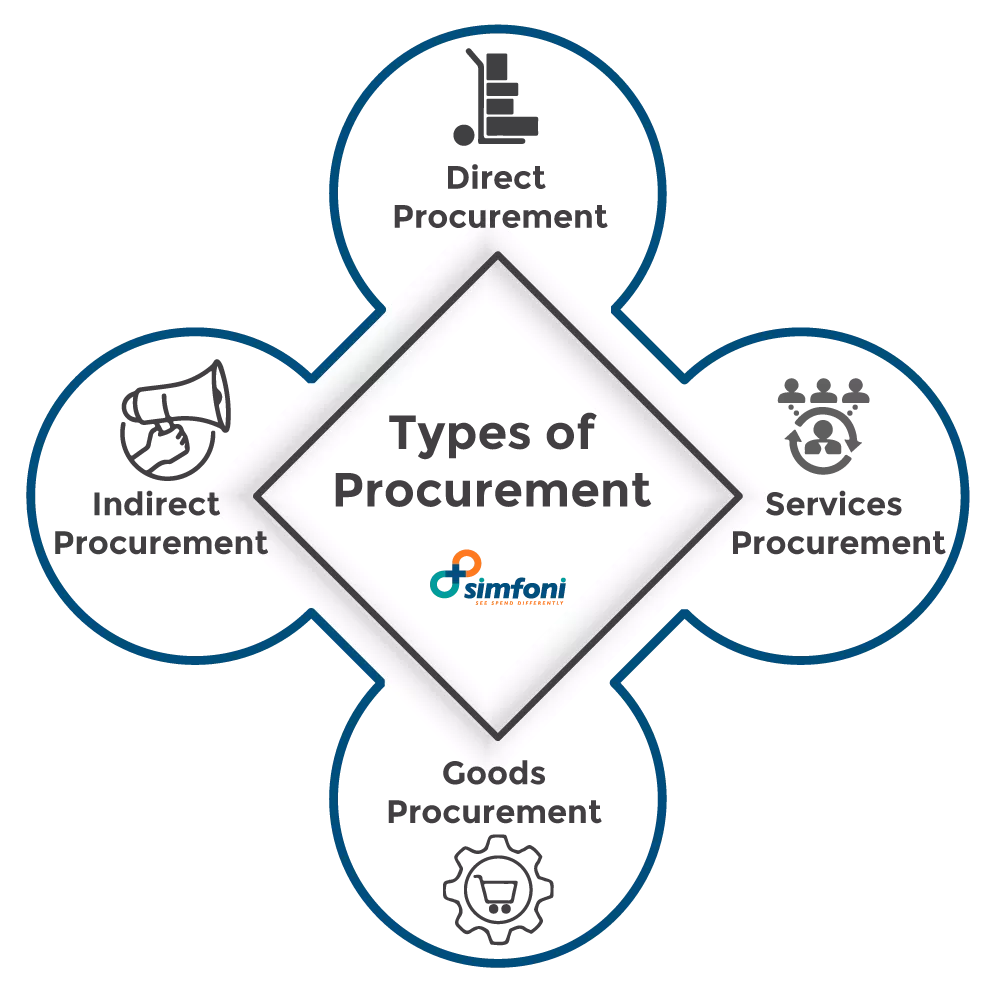

There are numerous classifications for procurement. Depending on how the organization intends to use the things purchased, it can be categorised as direct or indirect procurement. Depending on the commodities being purchased, it can alternatively be classified as goods or services procurement.

1. Direct Procurement

The acquisition of the inputs that a company needs to make its end product is known as direct procurement. This is the raw material that is often required in the manufacturing industry.

The profitability and performance of a corporation are heavily influenced by the cost and efficiency of direct procurement. When the direct procurement procedure is stalled, the company’s capacity to create its goods is harmed.

2. Indirect Procurement

Indirect procurement refers to the acquisition of services or inputs that aren’t directly utilized in the production of a company’s product but are necessary for day-to-day operations. It might be office supplies or equipment upkeep. The running of the firm is hampered by delays in indirect procurement.

3. Goods procurement

The procurement of tangible goods is the most common type of procurement, but it may also involve software subscriptions.

Good supply chain management procedures are often required for effective commodities acquisition. Both direct and indirect purchases may be included.

4. Purchasing services

Procuring people-based services is the emphasis of services procurement. This might involve employing individual contractors, contingent labor, law firms, or on-site security services, depending on the organization. Both direct and indirect purchases may be included.

What is the procedure for procuring goods and services?

So, how does one go about procuring something? Businesses identify and perform particular processes to guarantee they can buy products and services to satisfy their criteria and accomplish their goals through the procurement process.

Procurement is crucial since it determines how much money a company can save. Businesses may guarantee that their objectives are realized by frequently evaluating the procurement process. When a process isn’t performing as it should or when business issues arise, changes might be made to it. Because the primary goal of procurement is to increase efficiency, companies must ensure that they get the most out of their process.

Because each company’s demands differ, the procurement procedure is not the same for everyone. Each company has its unique set of requirements, thus its procurement process will be distinct from that of another company with similar demands.

The 7 Steps to a Successful Procurement Process

The next stage is to develop the purchase process after determining its importance. The seven steps to a successful procurement process are as follows :

Step 1: Determine all business divisions’ needs for products and services.

When any of an organization’s business units require goods or services from an external supplier, the procurement cycle begins. As a result, the first stage in the procurement process is to identify and consolidate the needs of various business divisions within a company. This gives you visibility into your spending areas and categories, allowing you to use spend analysis to find cost-cutting opportunities.

Step 2: Make a list of potential providers and analyze them.

Following the identification of the business units’ requirements, the following stage is to develop a list of possible suppliers who might provide the goods/services. A basic online search or more formal measures such as RFPs, RFQs, and RFIs are used in this procedure.

The goal of this procedure is to assess potential suppliers. Pricing, service quality, industry reputation and recognitions, warranty and guarantee provisions, and customer service are some of the evaluation measures. Following the evaluation, the agreement is awarded to the provider that provides the most value and the best market pricing.

Step 3: Work out contracts with the chosen vendor.

The contract procedure begins when a provider has been chosen to meet an organization’s needs. For optimum value generation and to stimulate buyer-supplier collaboration, contracting is a critical step for every firm. This procedure entails evaluating important elements such as price structure, the scope of work, terms and conditions, and delivery dates, among others. More cost reduction options, including dynamic discounting, can be discovered through detailed contract analysis and negotiation.

Step 4: Create a purchase order and release it.

The next stage is to create a buy requisition after a company has finalized its contract with a supplier (PR). A PR provides a description of the product/service, pricing and quantity, information about the provider, and the approval process.

When a PR is accepted, the finance team sends the supplier a purchase order (P)O, which contains information such as the PO number, payment conditions, and supplier information.

Step 5: After getting an invoice, finish the payment procedure.

When a supplier receives a PO, he sends an invoice with the price of the desired products or services. The procurement team matches the Pos to assure quality and quantity when the business receives and invoices the PO.

Payment is issued either before or after delivery, depending on the payment conditions agreed upon by the organization and its suppliers.

Step 6: Receive and inspect goods/services that were requested.

The provider provides the goods/services based on payment and contractual terms. Companies should audit their suppliers upon receipt to confirm that they have satisfied their quality requirements.

Step 7: Keep meticulous invoicing records.

Following receipt of the delivery, it is critical to properly preserve all invoices to keep track of spending and the various expenditure categories within the company.

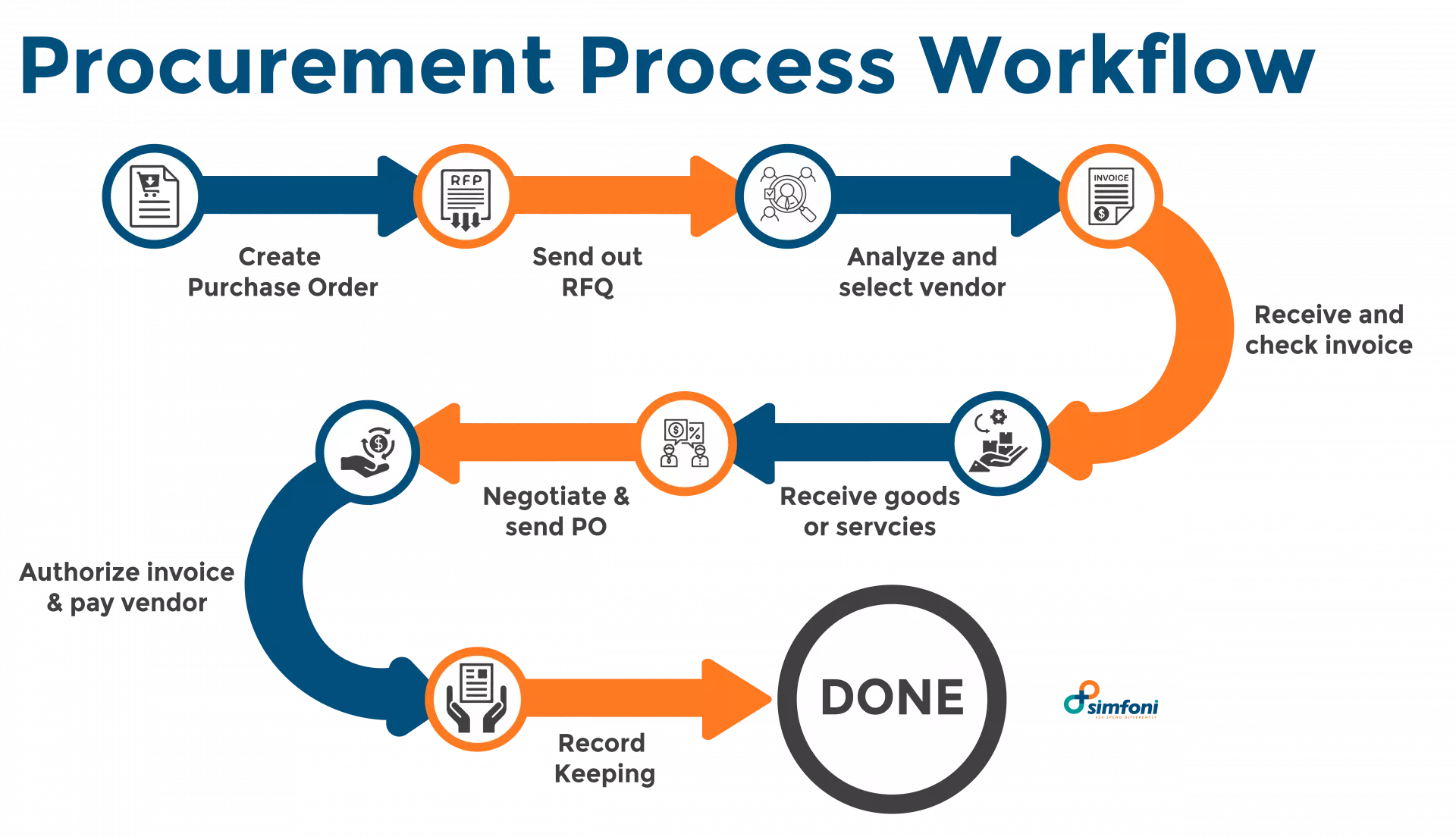

The Procurement Process Flow

Every company’s buying procedure is different. In business, however, procurement often begins with the identification of a need and the creation of a buy order that specifies all of the needs’ specifications. The purchase order will be forwarded to the relevant procurement or finance team for approval in a purchase when there is already an approved supplier for the demand. If it’s refused, you’ll get a letter explaining why. The purchase order is converted into a buy requisition once it has been approved.

The procurement team puts out numerous RFQs (Request for Quotations) specifying the parameters provided in the purchase order for purchases that do not have a pre-approved supplier or vendor. The obtained quotations are examined, and a suitable vendor is chosen. After that, the procurement team negotiates a favorable deal with the chosen vendor and issues a buy order.

When the bought products are received, a three-way matching verification is performed on the vendor’s invoice. The comparison and verification of the purchase order, vendor’s invoice, and the actual delivery of the products are known as three-way matching.

This stage verifies that the organization made the order with the designated vendor and that the vendor has delivered and billed the goods in accordance with the purchase order. The receipt of the products is then compared to verify if the order was received as requested and as invoiced. The vendor’s invoice is authorized and payment is sent to the vendor when the three-way verification is complete. The finance department is in charge of accounting for the money.

Procurement Workflow Steps

Organizations must take specific steps to ensure that their procurement strategy is successful, beneficial, and ultimately secures their market position. A creative and effective procurement process workflow is the solution to all of these criteria, from determining what sort of goods and services a firm requires, their quality, and pricing, to keeping track of all the required papers and files. Let’s take a closer look at each stage.

Step 1: You Must Be Recognized

Companies must first identify and acknowledge the demand for certain items in all sectors of their organization before they can begin the process of buying goods and services.

This is the first stage of the procurement cycle, and it is at this stage that businesses must strategize and, as a result, develop an effective plan for what goods and services they should purchase from an external supplier.

Business divisions inside a firm will also need to devise a strategy for determining how much they are willing to pay for items, as well as when and how they will need them.

Another thing to remember at this stage of the cycle is to keep all important stakeholders up to date on what’s going on to minimize any disputes later on.

Step 2: Create a Purchase Requisition

A buy requisition process is initiated when an employee of a firm files a procurement request or when clients seek the marketing team’s assistance in acquiring a certain product.

As a result, purchase requisitions are basically paperwork (digitized in today’s world) that allows businesses to collect information on what items they need to buy when they need to buy them, how many of them they need (demand and supply), and so on.

Step 3: Review the Requisition

At this point in the procurement cycle, the purchase procedure formally starts. A buy order may only be issued when a purchase request has been validated, approved, and examined for budget reasons by procurement managers, financial controllers, or persons responsible for procurement within an organization.

Essentially, the procurement team goes over a request package and determines whether there is valid demand for the products or service at this point. Employees also take steps to study and analyze the product’s parameters, such as the number of units necessary and the product’s technicalities, as well as ensuring that the organization has adequate finances to complete the purchase.

The procurement team must also take the appropriate safeguards to ensure that all departments engaged in the acquisition are kept up to date on what is going on, to avoid costly mistakes later on.

Step 4: Solicitation

The organization sets out to build a particular and thorough procurement strategy with an associated solicitation process soon after the procurement team approves a buy request and the following purchase order has been placed.

Based on the intricacy of the demand, the team will decide where the procurement strategy should go. After determining the budget for the purchase, procurement professionals will issue Requests For Quotation (RFQ) to a variety of external vendors.

While some businesses have an authorized supplier catalog with a list of vendors who have previously completed the selection process, others must compare quotes from suppliers to identify which vendors they may approach for their current needs.

Step 5: Assessing and Choosing

Following the completion of the solicitation procedure, financial controllers and the evaluation committee can begin analyzing and assessing vendor bids. Businesses can choose which vendor is most suited for their present need at this point in the procurement procedure.

Businesses often consider other characteristics of a supplier’s worth when determining whether or not they are a good fit for them.

Organizations would already have a supplier list on hand if the purchase order is just a duplicate of past buys. As a result, firms would not have to worry about obtaining high-quality supplies. Companies would also save a lot of time since they wouldn’t have to evaluate providers.

However, if a purchase order is relatively new, with new goods on the list, firms must devote time and effort in researching suppliers to see whether they can be trusted for quality and cost, as well as their reputation and timeliness of service.

Accountability, ease of communication, manufacturing skills, ethicality, and how they prioritize relationship creation and maintenance are some of the other characteristics that firms seek in a supplier.

Step 6: Finalize the price and terms of the contract by negotiating it.

Financial controllers and procurement teams decide on a provider for the current demand at this point in the cycle. In most cases, businesses choose a provider based on at least three bids. Businesses make their ultimate decision after closely examining the quote based on cost-effectiveness, product quality, delivery speed, and so on.

If the firm has started a bidding process to identify a supplier, the vendor will be picked based on the bid’s conditions and criteria. This selection procedure is open and transparent for businesses to choose vendors that can provide high-quality items at the greatest pricing.

Companies can sign contracts once the terms of the contracts have been agreed and negotiated, taking into consideration delivery schedules and other factors. Following that, the supplier receives a copy of the purchase order. When a vendor accepts and recognizes a purchase order, a legally binding contract is formed with the customer.

Step 7: Managing Orders

Order management occurs when a provider provides the requested products and services within the agreed-upon deadline. When the items are in the buyer’s hands, the firm conducts a comprehensive examination of the order and notifies the supplier of any inconsistencies discovered throughout the process.

Businesses ensure that they have the purchase order, packaging slips, and supplier invoices (the three-way matching system) on hand when doing so, making order administration a simple, straightforward, and smooth procedure.

Step 8: Approval of Invoices and Disputes

Companies will go on to approve the invoice and evaluate documentation relating to the transaction once they have accepted the order and its subsequent investigation has satisfied the buyer.

The papers are evaluated and compared for inconsistencies once an organization is happy with the purchase requirements and content with the delivery of things and payment request invoices. The invoice is accepted, and payment is made according to pre-existing terms if the firm is satisfied that there are no anomalies.

Step 9: Keeping and Reviewing Records

Businesses retain a thorough record of all necessary papers to simplify things for taxation, the auditing process, and bookkeeping. This is the situation once a purchase order’s payment procedure is finished.

Purchase orders, order receipts, and previously authorized invoices are all kept in one place. Because record-keeping is a continual process, these papers are checked regularly to avoid any potential disagreements between a firm and its supplier.

A comprehensive assessment of data may also help firms and vendors avoid repeating mistakes, helping them to be more efficient in the process. Accounting automation is an excellent approach to streamline the process while also collecting and storing vital financial data.

What is the Process of Purchasing?

There are several phases to the procurement process in general. The corporation determines the goods and/or services it requires, then seeks suppliers who can assist it in achieving its goals, negotiates terms and pricing, and finally acquires and gets the commodities.

In a small business, the procurement of all goods and services may be handled by a single individual. Larger businesses may have a staff dedicated to working with various suppliers or supporting certain internal business units. In order to assess the company’s overall requirements, the team may need to get feedback from many business groups on some things.

Procurement is a continuous process, not a collection of individual activities. Businesses, for example, typically want to create connections with important suppliers to acquire the best service and lowest costs possible, which translates to larger profit margins. To ensure that suppliers continuously fulfill expectations, companies may need to undertake frequent quality assurance tests and performance analyses.

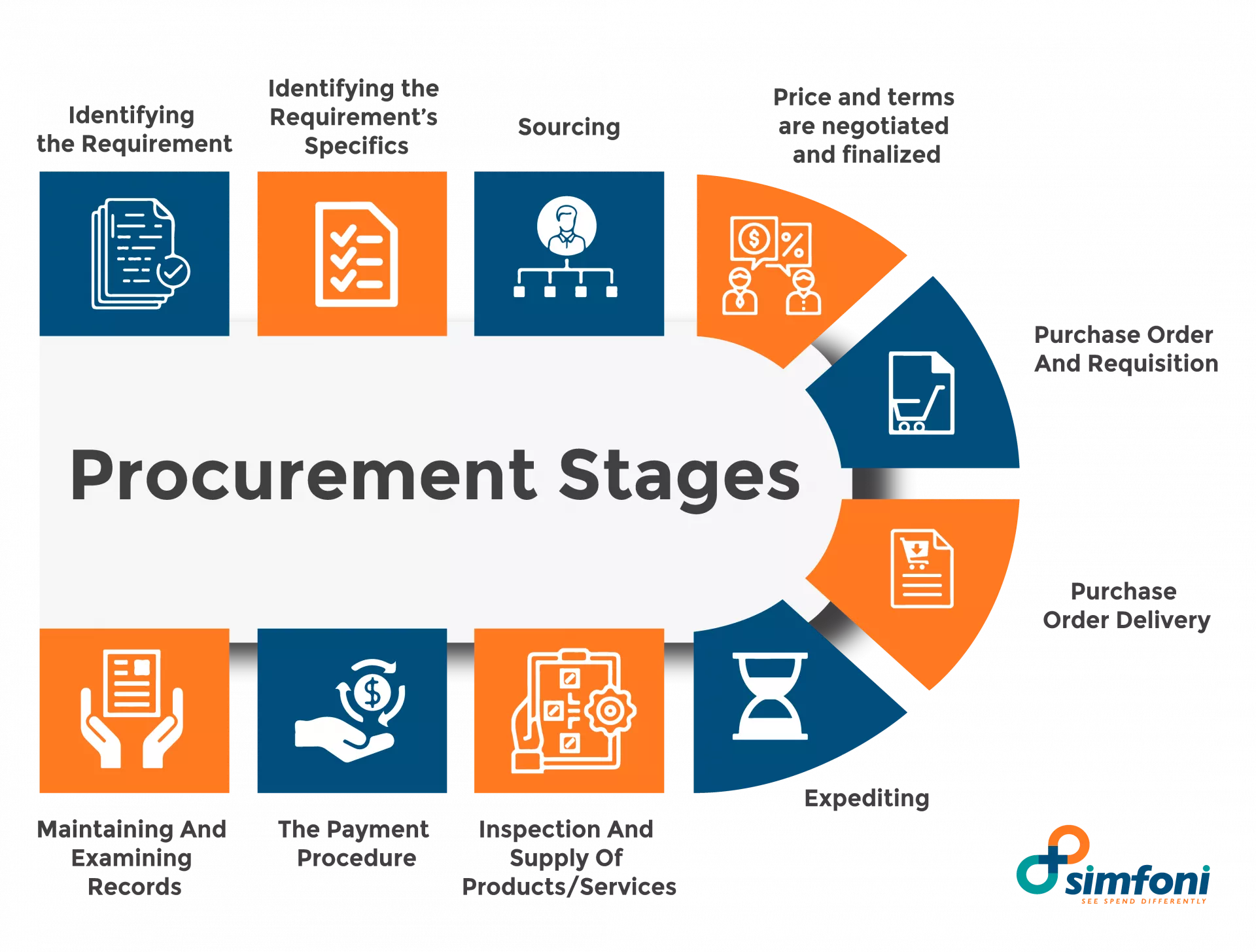

Procurement Stages

The following are the steps involved in procurement :

1. Identifying the Requirement

The first step in purchasing something is to recognize that it is required. This might include determining the need to purchase a new item or restocking an item when it is needed or falls below a specific stock level. In most firms, this will entail a requisition procedure. To avoid problems later in the procurement process, all stakeholders must be consulted at this point.

2. Identifying the Requirement’s Specifics

Once a need has been established, the specifications of the product or service required must be determined. Technical specs or component numbers are examples of this type of information. If the item has never been purchased before, a list of specifications is created with the input of all technical personnel concerned. Preventing costly mistakes later in the procurement process requires detailed specifications and good collaboration with all departments involved.

3. Sourcing

When a certain item or service is decided to be purchased, the procurement team must conduct the necessary research to identify the various suppliers. A pre-existing vendor list for recurring orders is frequently available. Identifying and then evaluating vendors for a new item takes longer. Working with a pre-existing vendor who has previously shown to be a good provider is more efficient. New suppliers must be extensively explored to assess their reputation, speed, quality, dependability, and costs. During this period, companies like Beroe can assist procurement departments by providing market intelligence data that would allow them to make better judgments.

The procurement department must next research providers, acquire estimates for the required item, and choose a vendor. This is a crucial step since reputation, pricing, service speed, and dependability must all be considered before making a final pick. The general norm is to obtain at least three estimates, although this is a best practice that will be chosen by your company. Based on the sourcing alternatives and prices involved, approval from the appropriate levels of management will be required. The request for proposals, bids, or tenders will have to be publicized if the order involves a bidding or tendering procedure.

4. Price and terms are negotiated and finalized.

Requests for bids will be addressed to the merchants who have been chosen for direct purchasing. Before making a decision, it is standard practice to obtain at least three bids. The price and speed of the quote will be compared. The firm to purchase from will be chosen based on promptness, dependability, and quality, in addition to pricing.

If the procurement is subject to a bidding or tendering procedure, the qualifying offers will be chosen according to the terms and circumstances established. The chosen provider shall be picked and announced in accordance with the established procedure, ideally in a transparent way.

To guarantee that the buyer receives the greatest value and quality of supply, the process of selecting among the numerous bidders must be fair and transparent. When the selection process is tainted, the value of the goods or services provided may be tainted as well.

The buyer must now choose between having a single high-volume provider and selecting several vendors. The increased number of orders affords stronger bargaining leverage when negotiating pricing when using a single supplier. However, if a single supplier fails to fulfill an order, the entire production process would be disrupted. Having many suppliers for a given item lowers risks while also limiting the amount of flexibility for rate negotiation. Multiple suppliers can sometimes aid in the development of price and quality competition.

5. Purchase Order And Requisition

The relevant authority will authorize a purchase request that is created within the firm. This will generate a purchase order containing all of the order’s details as well as the terms and conditions. Some businesses include the buyer in the process of creating the order’s specifications, ensuring that both the buyer and the supplier are aware of the order’s details. To avoid making any errors, the requirements must be carefully matched to the purchase request and the supplier’s offer.

6. Purchase Order Delivery

Wherever possible, the customer is notified about the shipping. The buyer’s and seller’s procedures determine how quickly the purchase order is delivered. It can be done face to face, through fax, or via email. This is also per the buyer’s and seller’s agreed-upon specifications.

7. Expediting

This entails planning a timeframe for the timely delivery of the desired products or services, taking into account any unexpected delays. It might also include payment and delivery schedule information.

8. Inspection And Supply Of Products/Services

The buyer receives the finished product or service when it is ready. It is the buyer’s obligation to verify the provided things extensively to see if they match the purchase order that was agreed upon. It might be approved or rejected by the buyer. Both selections will cause events to occur by the terms and circumstances that have been agreed upon. When the customer accepts the merchandise, the payment procedure begins.

9. The Payment Procedure

The paperwork pertaining to the order is evaluated in preparation for payment. The original purchase order, item receipt, and payment request invoice are all compared. Any discrepancies are ironed out before payment is made. Payment is made according to the agreed-upon payment methods once payment has been accepted.

10. Maintaining And Examining Records

For auditing and taxes purposes, both entities, the buyer and seller, keep records. The entire procedure should be reviewed regularly to enhance and resolve any potential conflicts. Reevaluation improves the efficiency of the procurement process and avoids disagreements from recurring.

The procurement stages outlined above differ from company to company, but the logical flow is consistent. Procurement processes that are efficient ensure that products and services are delivered quickly and without delay.

It is also the job of those participating in the process to stay on top of discussions at all stages to guarantee that the goods and services bought to meet the exact specifications, are of the best quality, and are offered at the most competitive price. Excellent record-keeping aids not only in record audits but also in restocking the same things. A fair supply of high-quality merchandise is ensured via ethical vendor selection.

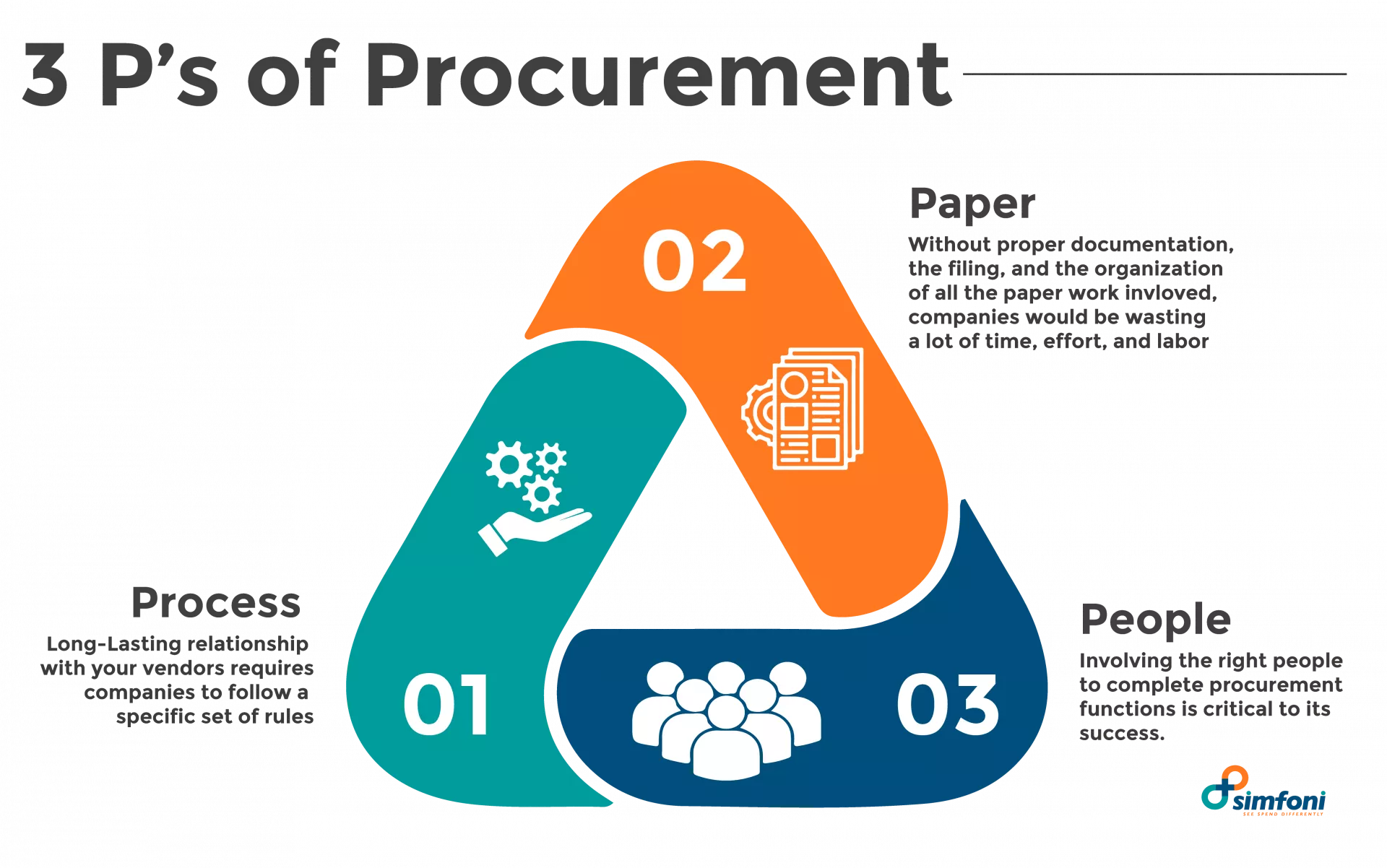

Components of Procurement

Procurement is divided into three components :

1. People

The number of persons participating in the procurement process is determined by the sale of the product and the number of procurement orders. Procurement personnel are in short supply at a small firm.

Each stage of the procurement process is overseen by a separate staff in larger firms. In addition, the number of approvals is lower when the things being ordered are of low value. The degree of approval for the buy requisition in the management order is greater for high-value or highly critical procurements.

2. Process

To work successfully, the procurement process must be well-designed and managed. When a procurement department is chaotic, it leads to inefficiencies and inconsistencies across the process, which can result in delays and difficulties with purchases and payments. At every level of the process, transparency assures that there is no corruption or manipulation.

3. Records or paperwork

It is critical to retain records at every stage of the purchase process. Although practically every step of the process has been digitized, both the buyer and the seller benefit from the efficient capture of all information at each level, as well as the coordination and comparison of all relevant data at each stage.

What’s the Difference Between Purchasing, Procurement, and Supply Chain?

Procurement, purchasing, sourcing, and supply chain are all phrases that are frequently thrown about. There are, nevertheless, key differences between them.

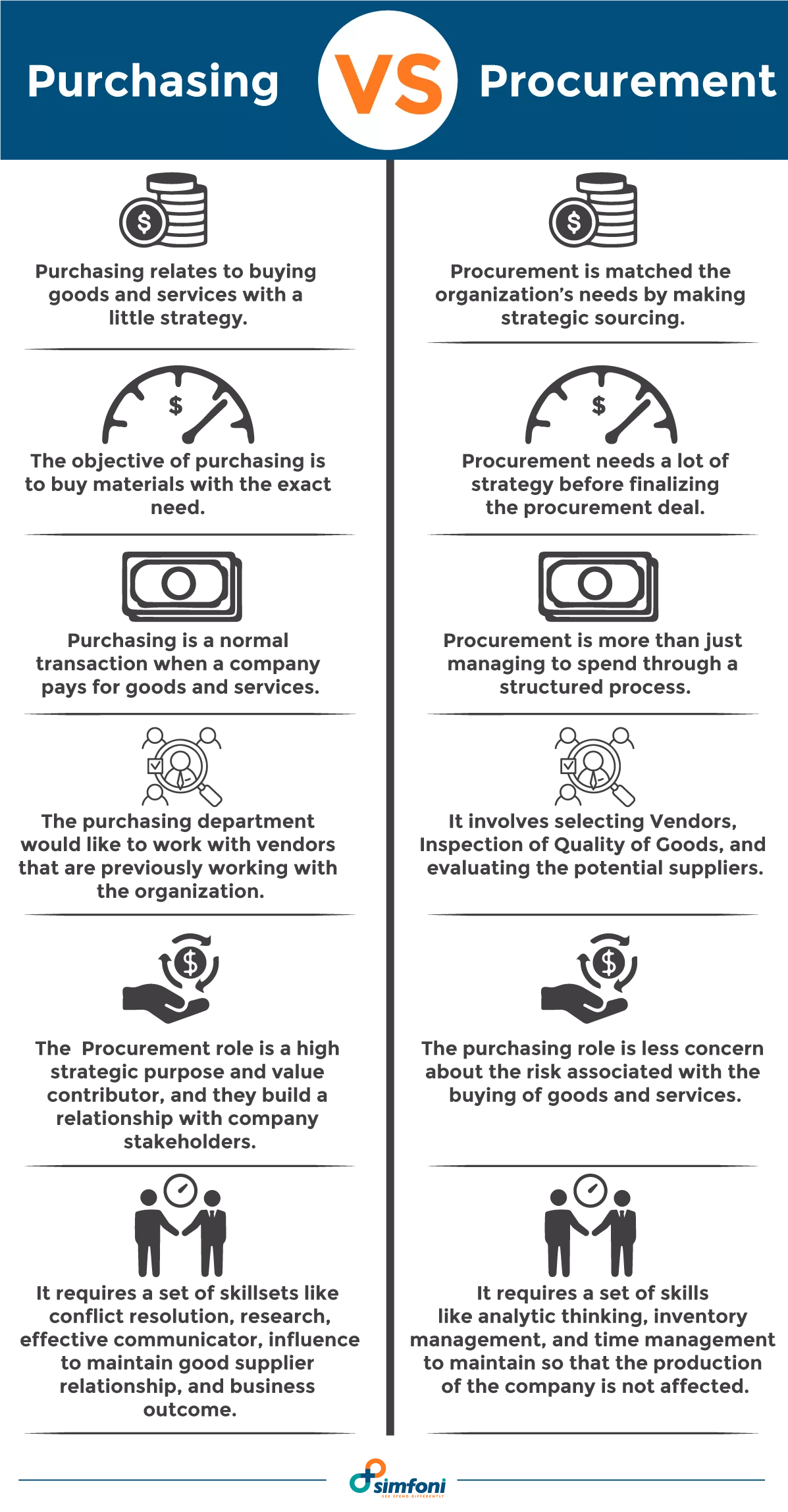

Purchasing vs. Procurement: Which is Better?

You might be asking what the distinction is between purchase and procurement if procurement entails purchasing. The explanation is that purchasing is mostly transactional, with an emphasis on handling specific orders to suit business objectives. Establishing and sustaining supplier connections are part of the procurement process, which is considerably larger and more complex. Another way to think about the distinction between purchase and procurement is that procurement is proactive and begins with an analysis of the firm’s needs, whereas purchasing is reactive and focuses only on getting what the organization has already determined it requires.

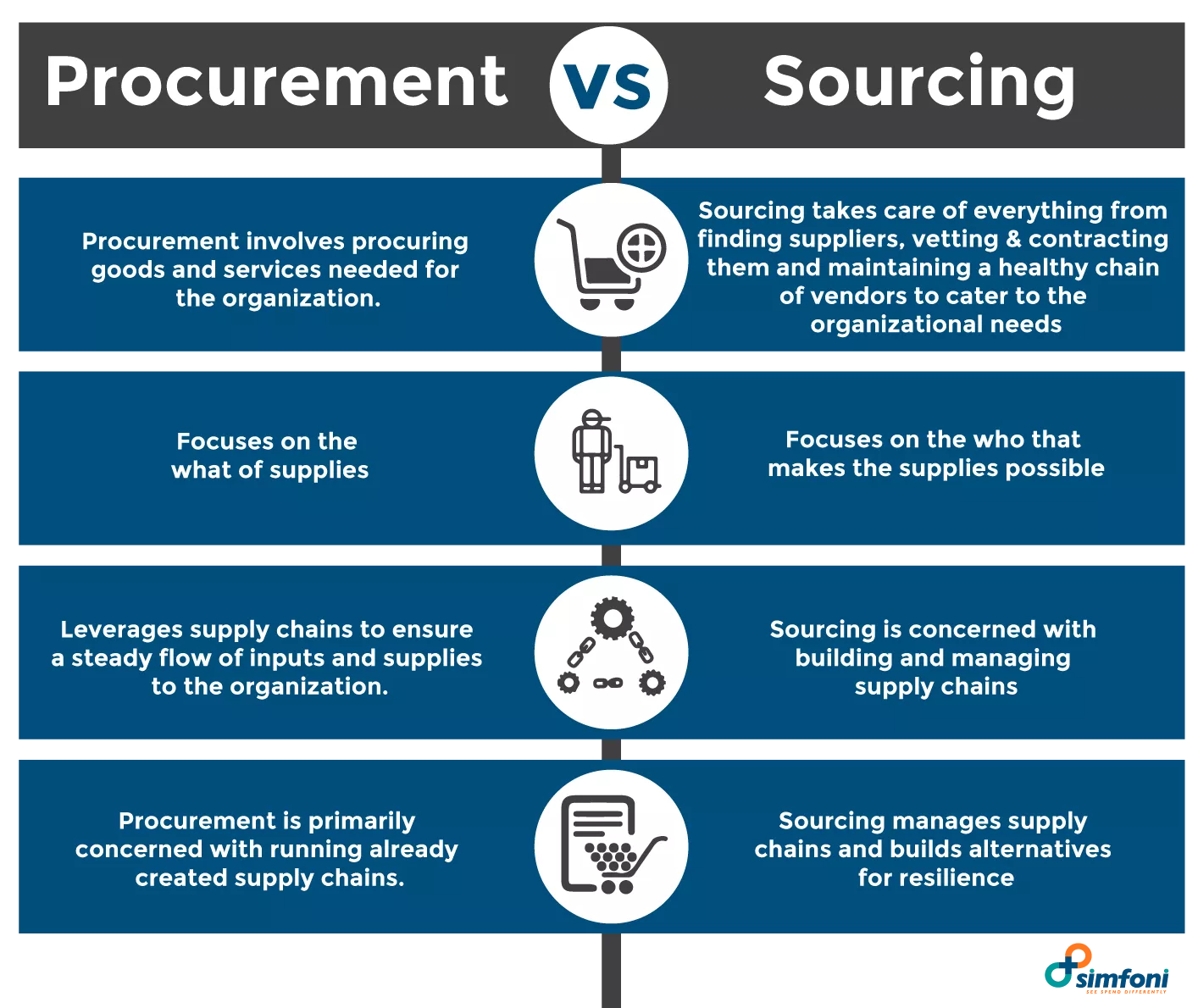

Sourcing vs. Procurement: Which is Right for You?

Sourcing, like purchasing, is just one step in the whole procurement process. The procurement cycle begins with sourcing. It includes tasks including discovering and evaluating possible suppliers of goods or services, negotiating terms, and selecting the vendors that best fit the company’s requirements.

Procurement vs. Supply Chain: Which is Better?

One facet of supply chain management is procurement. Purchasing products and services entail locating, acquiring, and paying for them. Supply chain management also includes logistics like shipping and warehouse management, as well as the transformation of bought items into products and their distribution to customers.

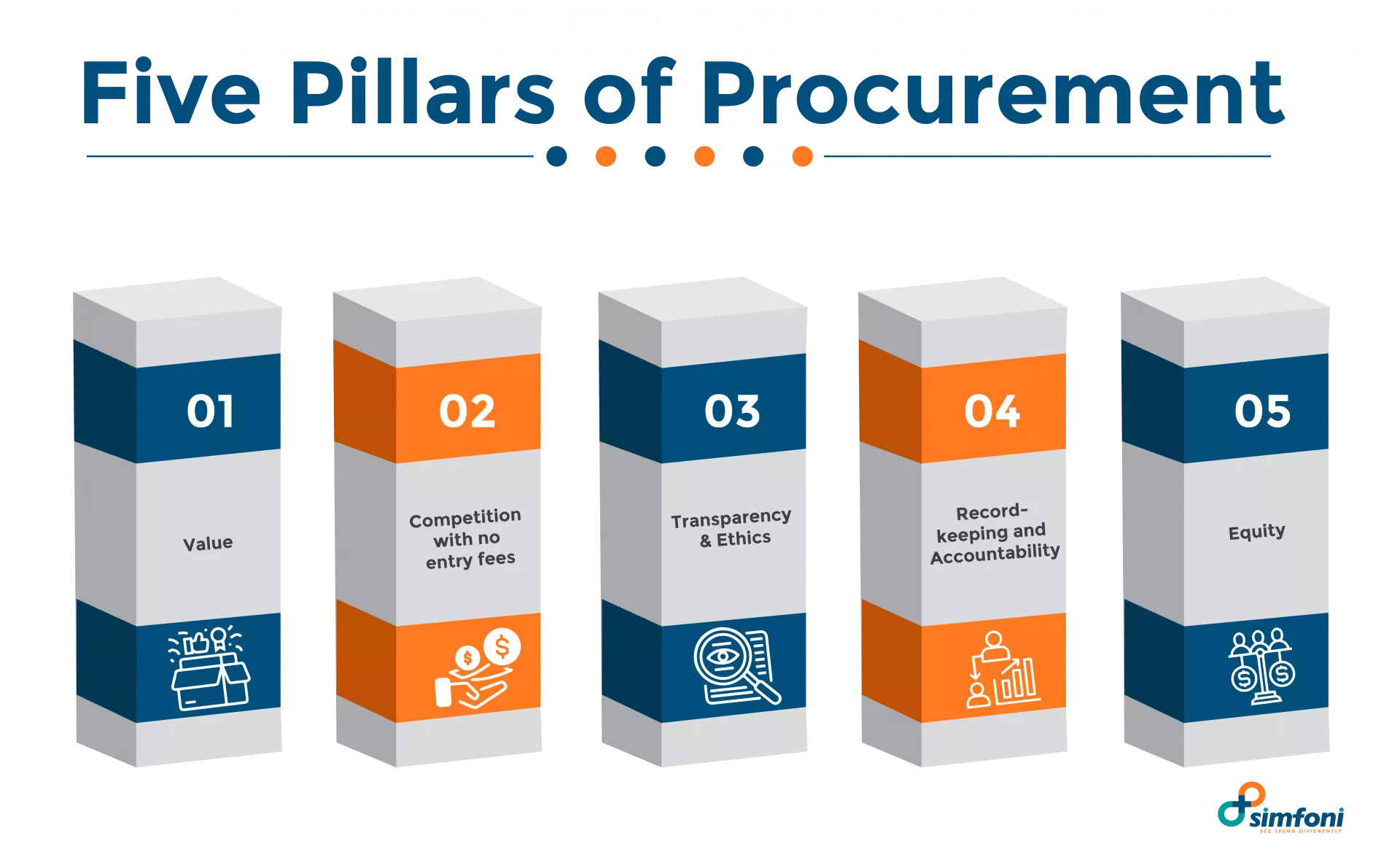

Five Pillars of Procurement

1. Value

The cheapest choice for a provider isn’t necessarily the best. The value should guide the procurement process. The customer should strive to obtain the highest quality goods that are also the most cost-effective. It has a cascading impact on the company’s completed goods or services when a customer compromises on the quality of the input based on the lowest cost. The most important consideration when choosing a provider should be value for money.

2. Competition with no entry fees

A level playing field for all vendors is ensured by creating a bias-free and transparent vendor selection procedure. The buyer benefits from this free competition since he or she can acquire the greatest deal.

3. Transparency & Ethics

Whether through direct purchase, tenders, or bids, the selection procedure for a vendor is extremely prone to corruption. Any unethical activities used to influence the vendor selection process will have a negative impact on the quality and value of the products purchased.

4. Record-keeping and Accountability

Each person involved in the procurement process should be held accountable for their actions. Procurement stages may be more easily traced with good record-keeping processes.

5. Equity

Having a fair and standard procurement procedure across all industries gives all participants an equal chance to succeed.

Models of Procurement

A procurement model is a set of processes that a company or organization takes to acquire goods or services. The degrees of hierarchy, control, and decision-making in procurement are also defined by procurement models. The finer points of a procurement strategy are generally specific to each organization and its operating environment.

Many departments and divisions exist in big organizations, some of which may or may not be geographically dispersed. Management decisions can be made centrally or locally. The control over the purchase process may be grouped into several procurement models.

The Local Procurement Model :

Control and decision-making are done at the local or departmental level under this procurement paradigm, which is not centralized. Procurement choices would be completely within the discretion of the local division or department.

This strategy is based on the assumption that local management would have a better understanding of the department’s specific demands. It allows for a more flexible procurement strategy with fewer layers of bureaucracy. There’s always the possibility of making rash spending decisions without considering the big picture.

The Centralized Procurement Model :

The central procurement approach gives central management complete control over procurement choices. All procurement must go via a centralized approval procedure, and central regulations apply to all local choices. When making purchasing selections, such a procurement model keeps the company’s or organization’s total budget and spending in mind.

Personnel with experience and dedication to the task conduct purchase negotiations. When purchasing in bulk, you also get a better price. However, there’s a chance that you won’t satisfy all of the specific requirements that each local level has. The procedure is complicated by the several levels of bureaucracy involved.

Hybrid Model :

A hybrid procurement approach, which combines localized and central procurement, is used by certain businesses. Some purchases are made centrally, while others are made locally in this arrangement. This approach combines the best features of both models, allowing the local departments some autonomy while remaining under organizational management. A center-led procurement paradigm is another name for it.

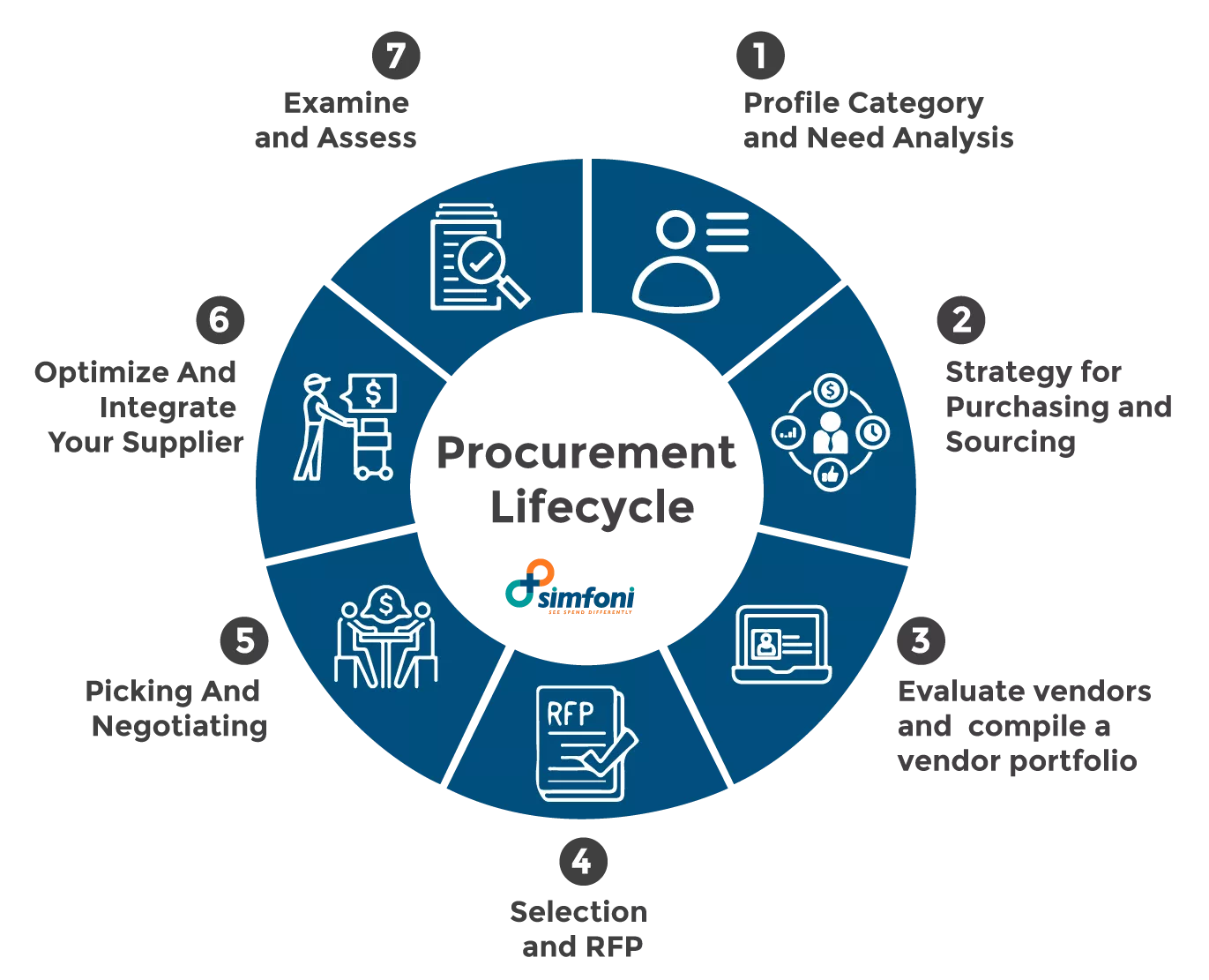

Lifecycle of Procurement

The phases in a company’s procurement life cycle are frequently customized to meet the company’s specific requirements. Some firms may combine the processes in the procurement life cycle, while others may have multiple sub-categories.

1. Profile Category and Need Analysis

The organization must first determine the demand and the specifics of what needs to be bought at this stage of the procurement process. Internally, the corporation should identify the real business requirement, budget allocation for the spending, and other facts. After that, the corporation would do external market research to learn about the item’s cost and other general characteristics.

All of the information obtained at this point, both internally and outside, serves as the foundation for the entire procurement plan that will be applied. This step of the procurement life cycle often involves personnel from all levels of the organization as well as data from outside sources.

2. Strategy for Purchasing and Sourcing

A sourcing strategy is developed using the data gathered in the first phase of the procurement process. If an existing policy is in place, it may be tweaked to better suit the present situation and eliminate earlier inefficiencies and difficulties.

3. Evaluate vendors and compile a vendor portfolio

The information acquired during the first market research may be used to develop a list of supplier criteria. Some businesses have a pre-approved supplier portfolio, which includes a list of vendors that have been selected through discussions. The benefit of having a pre-approved supplier list is that the firm may try to establish a solid working relationship with a group of suppliers to obtain the greatest pricing and value. It also saves time spent negotiating with new potential suppliers each time a procurement requirement arises.

4. Selection and RFP

For the procurement, a template and criteria for a Request For Proposal (RFP) might be established or updated from an existing RFP. The guidelines for the selecting procedure are clearly specified.

5. Picking And Negotiating

A vendor is chosen and the best price and terms for the purchase are negotiated at this step in the procurement process.

6. Optimize And Integrate Your Supplier

The supplier is incorporated into the organization’s overall process after the method for procuring from a new supplier is in place. Any faults will be addressed and modified to maximize supply efficiency and value.

7. Examine and Assess

The procurement life cycle should be examined regularly once it has been completed to ensure that the entire process is running well. It’s important to keep an eye on any outliers in terms of the supplier’s procurement process performance or failure. In the following procurement lifecycle, these lessons should be incorporated.

Being receptive to input from the supplier and other stakeholders in the process might aid in determining whether or not there is any room for improvement.

Procurement Principles

The procurement process in public-sector organizations is similar to that in private-sector firms, but there are a few key distinctions. Because they are dealing with public monies, those participating in the procurement process are required to follow strict guidelines. These guidelines might be thought of as an ethical code of conduct that makes government employees accountable for their purchases. Some of the ideas may also apply to private-sector businesses.

Depending on the organization, the principles differ slightly. Seven of the most popular procurement concepts are listed below :

- Cost-effectiveness: When acquiring products and services, the firm must handle cash effectively and efficiently. Cost-benefit analyses and risk assessments are examples of this. It’s important to remember that a low price does not always imply a higher value; qualities like quality and durability also play a role in assessing if a purchase is worthwhile.

- Fairness: Individuals or suppliers should not be given special consideration in procurement. All proposals should be honestly evaluated based on how well they match the needs of the company.

- Competition: Unless there are special reasons not to, such as a sole-source provider where the item or service is only accessible from one vendor, organizations should seek competitive bids from numerous providers.

- Efficiency: To assist optimize value and prevent delays, procurement activities must be carried out effectively.

- Transparency: Organizations should make essential procurement information available to the public and suppliers alike. Only when there are legal or other compelling grounds to keep information private should it be kept private.

- Integrity: Those involved in public procurement should aim to be seen as trustworthy, dependable, honest, and accountable at all times. Funds must be used for the original purpose and in the best interests of the public.

- Accountability: Everyone participating in the procurement process is responsible for their decisions and actions. They must accurately disclose all purchase operations, including any mistakes.

What Is Procurement Software and Why Should You Use It?

Procurement software is a program or set of applications that allow businesses to automate purchasing procedures, inventory management, supplier management, contract lifecycle management, and invoicing management. The software apps work with your ERP system, whether it’s Oracle, SAP, or something else entirely. Because everything is housed in a central area, everyone can access it depending on their user rights, many systems also enable improved supplier relationship management.

These functions will be addressed by the increasingly powerful procurement management software available :

- Creating purchase orders based on need and having the relevant employees enter them into the system.

- Checking purchase orders for line items that need to be filled up by a vendor.

- Submitting outstanding purchase orders for approval or rejection to the relevant personnel.

- Automate the submission of electronic purchase orders to vendors.

- Send out reminders to customers to confirm recent purchase orders or cancelations.

- Keep a stock of items to avoid shortages.

- As items, materials, and services arrive, complete financial and inventory transactions.

- Gather data and analyze trends to optimize and maximize revenues.

- Simplify platform standardization and management.

Demand Planning

Not only does achieving customer expectations in terms of the product contribute to customer happiness. It also hinges on the ability to satisfy demand on schedule while maintaining high quality. The method through which an organization can properly foresee and plan for future swings in demand is known as demand planning. To accomplish so, all of the elements that might influence demand must be understood.

When demand planning goes wrong, there is either a shortage of commodities or an overstocked inventory that remains unsold. Both situations have a financial impact on the company. Demand planning enables a firm to better match rising and falling demand to boost profits and customer satisfaction.

Forecasting

When a business is proactive rather than reactive to demand fluctuations, demand planning is extremely beneficial. The most efficient use of money and other resources occurs when a company precisely predicts demand fluctuations and adapts its procurement and supply chain appropriately.

It’s just as vital to be aware of the present market situation and factors that might impact demand forecasting as it is to be aware of historical demand-related data. Current events, natural disasters, and other political crises are examples of these causes. The key to accurate demand planning is proper data collection and analysis. As technology progresses, this procedure is becoming more automated.

Demand Forecasting’s Benefits

Management of the Supply Chain

An organization’s ability to predict demand spikes is improved through demand planning. It guarantees that their supply chain can keep up with the increased demand. To maintain seamless operations during periods of high demand, all phases in the supply chain are planned ahead of time. The entire process will be more likely to go smoothly if all players, from procurement suppliers through the manufacturing line to the final buyer, are ready. If there is a chance of delays owing to demand surges, giving customers early notification will reduce complaints. Negotiating with all parties involved ahead of time will result in better terms and greater openness. Any repair or service tasks that need to be scheduled can be better planned using the demand prediction.

Proper labor management and production

When you plan for highs and lows in demand, you’ll always have the right amount of employees on hand. When demand drops, it’s a waste of money to hire too many people. During a surge in demand, having too few employees on hand might cause the manufacturing line to break down. Demand forecasting aids in the planning of temporary extra workers to handle the rising output. It improves capacity management, resource management, and production efficiency when all parts of production are in line with demand.

Cash Flow Management (CFM)

An organization’s cash flow can be better managed if it can predict demand patterns. It eliminates the risk of cash becoming trapped in unsold goods or raw materials. Financial advisors might also arrange for additional loans to cover the deficit if they anticipate a drop in demand.

Logistics Demand Forecasting

In logistics planning, demand forecasting is extremely significant. In both the incoming and departing directions, ill-planned logistics can disrupt the supply chain. Inadequate logistics may stymie the flow of both raw resources and finished commodities. Production might come to a standstill if the logistics for arriving supplies are inadequate. Unfulfilled orders and disgruntled customers are the outcomes of poor departing transportation of finished products. Demand forecasting should, in theory, allow for the provision of additional logistics assistance during anticipated demand spikes. Demand spikes across the board placed a strain on logistical providers. To avoid problems in such a case, extra warehousing would need to be planned ahead of time to warehouse incoming goods. Order fulfillment timetables would have to account for logistical delays as well.

Negotiating a Purchase Order

We’ve put up a list of six purchase negotiating techniques to help you win every sale.

Tip #1: The Good/Bad Guy Strategy

The Good Guy/Bad Guy technique is a common negotiating tactic in which a person (good guy) is with you negotiating a deal and appears to agree to your offer, but then can’t call the shots and has to march off to the manager (bad guy) for approval, who then disapproves the deal and sends it back to the « good guy » for renegotiation.

This is one of the six negotiating strategies that suggests informing the salesman that you don’t like the good/bad guy strategy and that you only want to speak with the authority who can provide you the final negotiated amount without any additional back and forth. You’ll be able to disarm the seller of any well-practiced tactic in this manner.

Tip #2: The Art of the Subtle Walk Away

In this circumstance, your supervisor needs you to complete a certain procurement as soon as feasible and at the greatest price available.

The second of the six bargaining techniques is to walk away from a deal that looks to be a good deal since the supplier claims it is the lowest price bid for you. The supplier is eager to sell you their goods, but how can you know whether they are being truthful? In business, a conservative understanding of statistics is equally important. As a result, mastering the skill of walking away establishes power, allowing you to influence pricing to your advantage.

Tip #3: Don’t Offer a Price Range; Instead, Offer an Exact Price

Avoid circumstances where the salesperson gives you a range of prices rather than an actual price since this will prevent you from getting the BATNA (best alternative to a negotiated agreement) benefit.

Typically, a range of pricing for a product that the buyer wants to acquire is presented in this type of negotiation, and it frequently ends in a price that is on the upper end of the range. They begin the negotiation with a larger price range, limiting your ability to bargain. As a result, the best advice is to avoid asking for the lowest price a provider can offer right away.

Tip #4: You Have the Right to Insist on a Price Reduction

What if a vendor is astute enough to quote a price that is implied in the sliding range? That is an excellent query. You should be aware that you are not negotiating with a single vendor in this scenario, and your supplier should be aware that other vendors have provided cheaper quotes. The negotiation isn’t done just because a salesperson proposes a price after you’ve refuted it. Until a contract is signed, the endeavor to lower the price might continue.

Tip #5: Don’t Let a Salesperson Ride Your Emotions

This is arguably the most crucial bargaining advice for a customer who may be a victim of a salesperson’s manipulative tactics, in which they try to play with your emotions. A skilled salesperson may attempt to enter your personal space and exploit your emotions.

So be sure to have your facts and objectives on hand, and keep the conversation on track. You may still have fun and create a connection, but do it with caution so that you always have the upper hand and the salesperson knows he’s dealing with a seasoned professional.

Tip #6: Use Evidence of Alternatives to Persuade Compromise

In a commercial transaction, compromise is as ancient as commerce itself. There must be some amount of discussion compromise, and you must not accept the beginning offer in any way.

As discussed in Point 4, it is critical to emphasize it so that you are aware that you, too, have options, but that you have evidence to back up your claims so that you are not dismissed by a seasoned salesperson. To stay in business with your market goodwill, the salesman must compromise on the transaction. You are, after all, the purchaser!

Strategies for Negotiating

The following are proven and true procurement negotiating strategies :

Understanding and Research :

The negotiator can better appreciate where there is an opportunity for discussion if they are familiar with all of the pertinent information. Knowing all of the motivators that drive the supplier as well as one’s own business allows one to have a deeper understanding of all of the aspects that go into a negotiation. Negotiating a fair bargain requires research and awareness of the technical and commercial components of the procurement item.

Explicitness :

Rather than agreeing to a price range, it is preferable to negotiate a clearly stated lowest price. Pricing that is explicitly mentioned and agreed upon eliminates future disagreements. If a price range is agreed upon, a higher price may be charged, which is unfavorable to the negotiator. There should be no opportunity for misunderstanding by explaining and agreeing on the technical and other parts of an agreement with utmost clarity and accuracy.

Expect Protracted Negotiations :

A one-meeting agreement is unusual in negotiations. It may take several rounds of negotiations until both parties are completely pleased with all of the parameters. Being persistent might provide positive outcomes if you realize there is an opportunity for bargaining. However, it takes a skilled negotiator to know when to walk away from a deal and change the tide in one’s favor.

Alternatives Must Be Concrete :

When discussions aren’t going as planned, it’s a good idea to show the opposing side that you have options. However, this should not be a hollow threat; evidence-based threats are more effective.

Bad-Guy/Good-Guy :

A common negotiating tactic is for the negotiator to say that the terms must be agreed upon by a higher authority. This puts a stumbling obstacle in the way of cutting rates or obtaining more advantageous arrangements. This approach may be avoided by clearly indicating that talks will only take place with the decision-making authority.

Prepare to Make Sacrifices :

Compromise on both sides of the table leads to a mutually acceptable solution. There is no space for compromise when you are rigid. The non-negotiable aspects must be kept in mind, while other factors must be willing to be compromised if necessary. When both sides gain from the connection, the chances of it lasting and succeeding are higher.

Techniques of Negotiation

Negotiation methods and approaches for successful procurement negotiations are the same.

- Planning: The significance of planning for any negotiation cannot be overstated. On both sides of the negotiation, adequate preparation and a complete understanding of the aspects involved speed up the process. Negotiations should not be hindered by repeated internal discussions if the negotiating team agrees on a procurement plan. Some negotiators go even farther and try to learn everything they can about the firm and the executives they’ll be dealing with.

- Agenda: Finalizing an agenda for the meeting so that both negotiating teams are on the same page saves a lot of time. Knowing the other team’s agenda means that you’re well-prepared with pertinent info and responses.

- Research the Firm’s History: It’s a good idea to research the company with whom you’re negotiating. It’ll aid you in anticipating their signature strategies. And if the organization has a strong track record for efficiency and quality, you’ll know that finding a reputable and dependable provider is well worth the effort.

- Pick Wise Team Members: It’s critical for all members of a negotiation team to communicate well with one another and to agree on the negotiating approach and aim. The group should agree on what they’re prepared to compromise on and how much they’re ready to give up. Negotiation outcomes will suffer if there is a lack of consensus among the team. It’s also a good idea to go through your bargaining approach with your team and decide on nonverbal communication methods.

- People Make an Organization: Don’t undervalue the importance of interpersonal skills. Every business is represented by a person at the end of the day. It is a good idea to attempt to get to know the opposing team.

- Summarise Clearly: After the negotiation, summarize all of the agreed-upon points so that all of the negotiators know what the other has comprehended. Misunderstandings and the need to renegotiate are avoided as a result of this. As quickly as possible, get everything in writing.

Typical Negotiation Errors

Negotiation blunders may be quite costly to a business.

- Inadequate Preparation: Failure to prepare adequately might result in protracted discussions or needless re-negotiations.

- Aggression: A win-win situation for both sides is the ideal outcome of a negotiation. Long-term, mutually beneficial connections are developed as a result of this. When one negotiator is overly aggressive and reluctant to compromise on any issue, the relationship as a whole suffers.

- Details: Failure to pay attention to all of the flaws may result in an agreement that appears to be fine on the surface but contains several loopholes and details that will ultimately harm the organization.

- Emotions: Because business talks are ultimately between groups of people, it’s easy for emotions to take precedence over other factors. Take a break if the discussion becomes heated.

- Ethics: Being ethical pays off in every situation. It might be quite tempting to take a clear shortcut, but this can have a negative influence on the business relationship. When the truth is disclosed, it will tarnish the negotiator’s reputation.

KPIs in Purchasing

The efficiency, efficacy, and standard of performance of a procurement strategy and process are measured using procurement KPIs, or key performance indicators.

Qualitative and Quantitative KPIs (Key Performance Indicators)

The quality and quantity of a purchase process’ performance should be assessed. By definition, quantitative KPIs may be expressed as a number. KPIs with a qualitative component, such as ease of doing business or customer happiness, is known as qualitative KPIs.

Monitor Key Performance Indicators (KPIs)

A business can choose from a wide range of KPIs to track. The following are the most essential KPIs for assessing procurement performance :

Performance Indicators for Purchase Orders

- Order Cycle Time: The time it takes for one order cycle to complete. This will aid in determining which provider is the most suitable for emergency supplies.

- Cost of Each Transaction: The cost of processing each purchase, which aids in keeping track of internal expenses. The time it takes to fulfill an order from the moment it is placed to the time it is delivered.

Key Performance Indicators for Supply

- Provider Availability: How prompt and available is the supplier in the event of a last-minute request or emergency order?

- Number of Suppliers: This will inform you if you rely on a small number of suppliers too much

- Quality, Accuracy, And Compliance: Determine whether or not the provider adheres to the standards in terms of quality and accuracy. Too many flaws and errors are expensive and time-consuming. Supplier Capacity: Identifying suppliers who can handle huge orders is critical.

- KPIs for Return On Investment

- Savings and Cost Avoidance: The amount of money saved by a corporation as a result of its procurement procedure. It is a savings when a procurement procedure assists in the elimination of certain expenditures.

- Total Return on Investment (ROI): The total return on investment of the procurement process.

Types of KPI's in Procurement

KPI’s for Inventory

How effectively inventory is handled has a big impact on the efficiency of a procurement cycle. Bottlenecks in the process are avoided with good warehouse and inventory management. The following are some of the most important inventory KPIs :

- Stock Accuracy: How well the books represent the inventory and how accurate the stock listings are.

- The expense of training

- The total number of trainees

- The rate of attrition

- High-performer turnover rate

- Internal promotion rate

- Percentage of performers that aren’t up to par

KPIs for delivery

The delivery process’ efficiency is a key part of procurement. The following KPIs can be used to assess delivery :

- Length of Time: Time it takes for a purchase order to be fulfilled

- Emergency Orders and Deliveries as a Percentage

- Availability of Suppliers

KPIs for quality

The following factors can be used to assess procurement quality :

- Defect Rate And Quality

- Rate of Adherence

- Accuracy

KPI for cost

The cost of procurement can be calculated as follows :

- Order Costs and Invoices

- ROI

- Authorized expenditures

- Price Competition Among Vendors

Best Practices in Procurement

How efficiently you weed out inefficiencies and tackle possible bottlenecks in your procurement system determines how well procurement performs in your firm. Here are the most effective techniques to re-energize your procurement cycle so that you can ensure long-term procurement success.

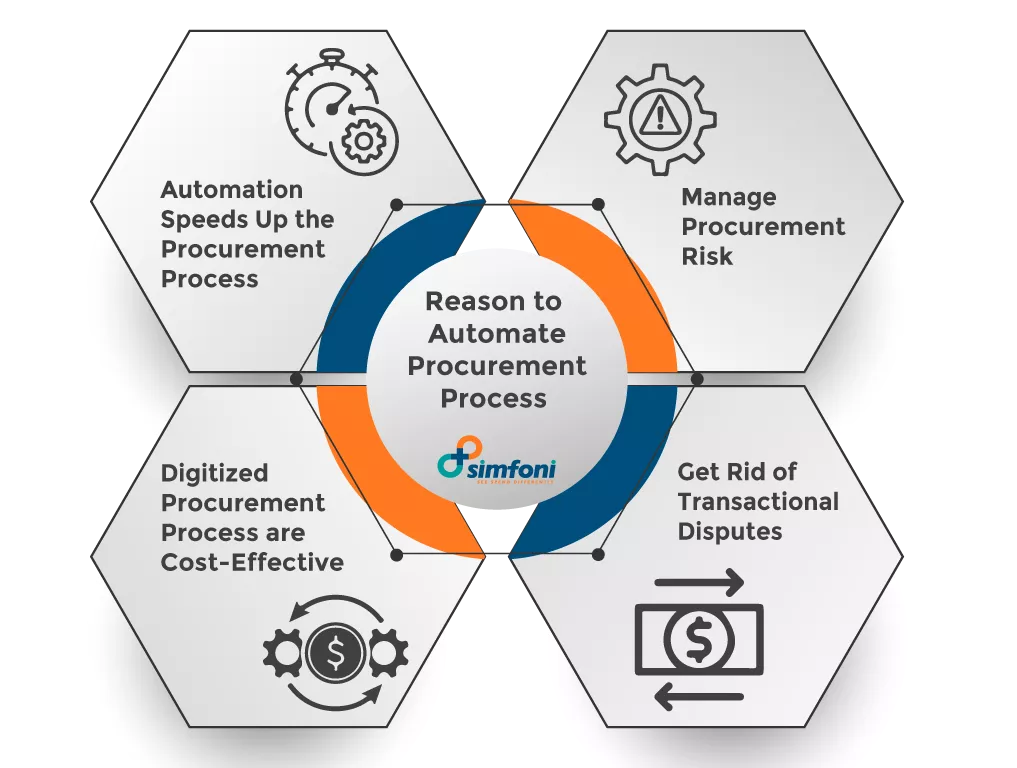

1. Make Procurement Processes More Automated

Procurement is a crucial component of your company’s operations and profit margins, thus it should be one of your primary business tasks. Purchasing teams, on the other hand, are frequently forced to operate with antiquated methods and equipment.

2. Have Well-Defined Processes

Processes should be effective and efficient to achieve operational efficiency. The issue is that inefficiency is frequently caused by a company’s lack of well-defined processes.

Teams can’t know which activities are critical at any given time or what steps to prioritize to finish the job without well-defined processes. Furthermore, personnel may have difficulty coordinating communications and project delivery among numerous stakeholders. Poorly specified procedures, on the other hand, lead to chaotic operations. Even if things get done using inefficient methods, the costs in terms of money, efficiency, productivity, morale, and other factors are likely to be significantly greater.

Duplicated requests accumulate excessive expenditures without defined procurement processes, and poor record-keeping causes lost time, delays, and other delivery interruptions.

3. Adopt a transparent process.

The most effective strategy to avoid procurement delays and bottlenecks, according to 27% of firms, is to increase supply chain openness.

Transparency in procurement entails providing all process stakeholders with essential paperwork and information to assist them in completing their separate portions in a timely and efficient manner.

Only half of the procurement executives have high or very high visibility into their tier one suppliers at the moment. The advantages of transparency, on the other hand, are obvious: firms with more visibility outperformed those with lower visibility.

4. Create a contract and documentation hub that is centrally located.

Inconsistencies between contracts, issues with contract administration, and contract mistakes are causing delays for 22% of organizations in the supply chain.

The majority of contract troubles stem from a single issue: a lack of a centralized location where employees can search, access, and retrieve contracts and other important documents.

Having all documents in one place, from operational processes to contract templates, ensures :

- Contracts and communications must be consistent.

- A reduction in mistakes

- Time spent on corrective work is reduced.

Consider creating a central repository for your contract templates and the latest versions of your most frequently used contracts.

Simple options, such as a Google Docs template repository or contract management software, are available.

5. Make Inventory Decisions Based on Data

Inventory optimization is critical due to the high expenses of inventory holding. Depending on the sort of organization, experts estimate it to be between 18 and 75 percent every year. Given the ongoing need to reduce expenses and simplify spending, maintaining adequate stock levels is a top priority. You’re paying extra logistical expenses because you have too much stock. You won’t be able to satisfy client expectations if you don’t have adequate inventory. That’s when data-driven insights come in handy.

Utilize sophisticated analytics and AI to establish ideal inventory levels at any given time and forecast future stock requirements. Currently, 39 percent of procurement professionals are using operational analytics to better manage company KPIs and indicators, while almost half of companies are seeking tools or solutions to improve supply chain tracking.

Furthermore, one out of every ten businesses uses AI to improve logistics, and another one out of every ten uses it to improve inventory management. While the procedure necessitates the implementation of new technology solutions, the data acquired will enable you to precisely estimate demand, preventing overstocking or undersupply.

6. Have a multi-sourcing strategy in place.

It’s not a good idea to rely on just one vendor for any part of your supply chain. If you only buy from one vendor, you risk bottlenecks and delays if that seller fails to deliver on schedule.

If you have issues with supplier management and the relationship breaks down, you’ll have delays as well. You won’t be able to achieve your final results until you find a substitute vendor if you just have one provider in the pipeline.

This is why 39% of businesses source their products from several vendors. It strengthens their procurement methods by reducing their reliance on a single supplier.

Not only that, but you should think about bringing in providers from diverse parts of the country. Uncontrollable factors like war, pandemics, geopolitical challenges and climatic change can wipe out a region’s providers.

To avoid this hazard, 30% of businesses seek to diversify their supply networks across several geographies. They won’t be caught off guard if a regional incident disrupts manufacturing.

7. Develop long-term relationships with your suppliers.

The greatest strategy to decrease supply chain interruptions and bottlenecks, according to 47% of companies, is to build supplier relationships. This is because excellent supplier management enhances transparency between you and the vendor, ensuring that both parties are aware of what is going on.

The supplier will notify you in advance of any issues or modifications, and you will keep them updated on any changes to the process or payment issues. As a result, you’ll be able to address any bottlenecks before they become a catastrophe. As a result, more than half of businesses are ramping up their supplier communication efforts. It allows them to spot possible problems before they happen. Furthermore, effective communication allows you to resolve any concerns that develop before the relationship becomes sour.

An excellent working connection with your supplier may also put you ahead of the line. If your provider is having trouble accommodating all of their customers, they are more inclined to assist those with whom they have a good relationship. Build strong ties to ensure that’s you.

8. Educate your procurement staff

The overall performance of teams and their capacity to consistently deliver on the organization’s greatest goals, such as cost and risk management, needs CPOs to create and implement successful people strategies, according to a recent Deloitte research.

In this regard, it is the procurement leader’s responsibility to ensure that your procurement team is up to date on all rules and practices. A well-trained crew is significantly more capable of completing tasks successfully and efficiently. They’ll also be better able to recognize and deal with problems before they become too big to handle.

That’s why, amid difficult circumstances, CPOs believe that empowering teams is their top priority. Ensure that formal procurement training is provided and that any changes to processes are communicated properly as they occur. Organize procedural paperwork so that employees know where to go for training materials. You’ll find it simple to hold your procurement employees accountable for any mistakes if you have a well-trained crew.

What Is Business Procurement?

The activity or process through which a business or organization sources or procures the goods or services it requires is known as procurement. It is the process of purchasing big amounts of services and products. Procurement is an important procedure since the materials or services purchased are often used to manufacture the company’s product.

The first step is to figure out what exactly the product or service needs are. The procurement research procedure discovers potential suppliers and issues a Request for Quotation to them (RFQ). Negotiation, an auction, or a tendering procedure are all used to choose a vendor. Following the selection of a vendor, the procurement department negotiates rates and terms with the chosen vendor before signing a contract.

After then, the necessary goods or services are ordered and delivered. Quality assurance checks are performed by the procurement department on the products and services received. The procurement team examines and oversees the whole process for efficiency, quality, and cost-effectiveness regularly.

What Is the Importance of Procurement in Business?

Procurement is an important part of understanding supply chains since it assists a firm in locating dependable suppliers that can deliver competitively priced goods and services that meet the company’s requirements. Whether the organization is looking for manufacturing raw materials, marketing services, or new office supplies, this is the situation.

For example, if a firm needs a new supplier to offer an ongoing service for an indeterminate amount of time, such as an email security solution, the procurement process can assist the company in selecting the provider that best satisfies all of the company’s criteria at a fair price. It helps the company to save time, money, and important resources by avoiding dealing with a subpar supplier.

One part of optimizing your procurement operations is to reduce costs. However, it’s also critical to choose suppliers that can produce the high-quality goods and services that the business requires, as well as have the capacity and track record to do so.

The Future of Procurement

Procurement evolves in tandem with market developments. Procurement management is constantly improving as organizations and enterprises expand outside geographical bounds.

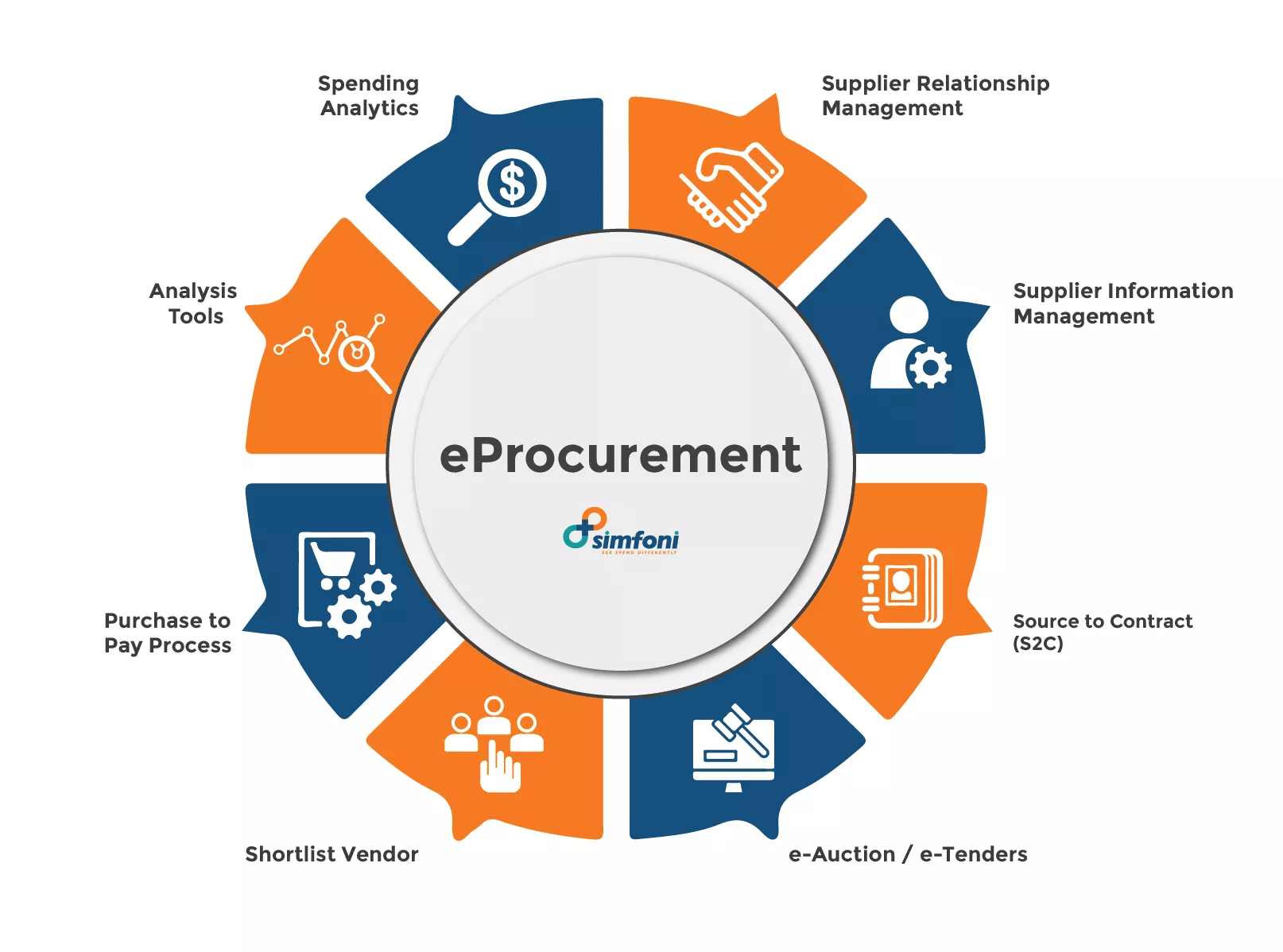

The use of eProcurement tools and software has decreased the cost of each stage in the procurement process while also improving efficiency. These systems’ UIs, or user interfaces, are getting more and more user-friendly every day. Apps for managing the full procurement lifecycle have enabled real-time data flow across all levels of management. Because of the digitization of procurement, enforcing the best standards and openness across the board is now simpler than ever. Data analysis, demand forecasting, and procurement management have become more of a science than a bet thanks to machine learning, Big Data, and artificial intelligence (AI). The eProcurement system is now accessible thanks to cloud-based technologies.

When the Covid-19 or new Coronavirus/Coronavirus epidemic in China halted supply chains, it demonstrated the global aspect of procurement. The globe was thrown into chaos as governments implemented lockdowns. Companies with a diversified network of suppliers from several geographies were better equipped to tap into other providers rapidly. The need to properly establish and implement supplier risk management strategies has been highlighted by this issue. Procurement systems that are agile and responsive are better suited to deal with the aftermath of such disasters. Making and implementing emergency sourcing choices has become easier thanks to the digital revolution of procurement.

Composable Procurement: A Novel Procurement Approach

Simfoni believes in Procurement that is composable. Instead of connecting several tools with countless APIs or purchasing a monolithic (all-in-one monster) you choose best-of-breed software modules – all from the same vendor – so they function together flawlessly and with your current systems.

What is Composable Procurement?

The term composable procurement refers to a procurement methodology where the services purchased by an organization can be assembled as part of a project. The procured goods are usually provided following a detailed scope of work.

Digital Procurement Transformation - Simfoni

Watch a Video on Simfoni's Procurement Platform.

Toss out the paper in favor of digital transformation and automation in procurement.

More than merely getting rid of paper copies is part of the digital transition. It incorporates features such as data collection, data analysis, and process automation. Workers’ capacity to make data-driven decisions is enhanced when cross-system flow increases.

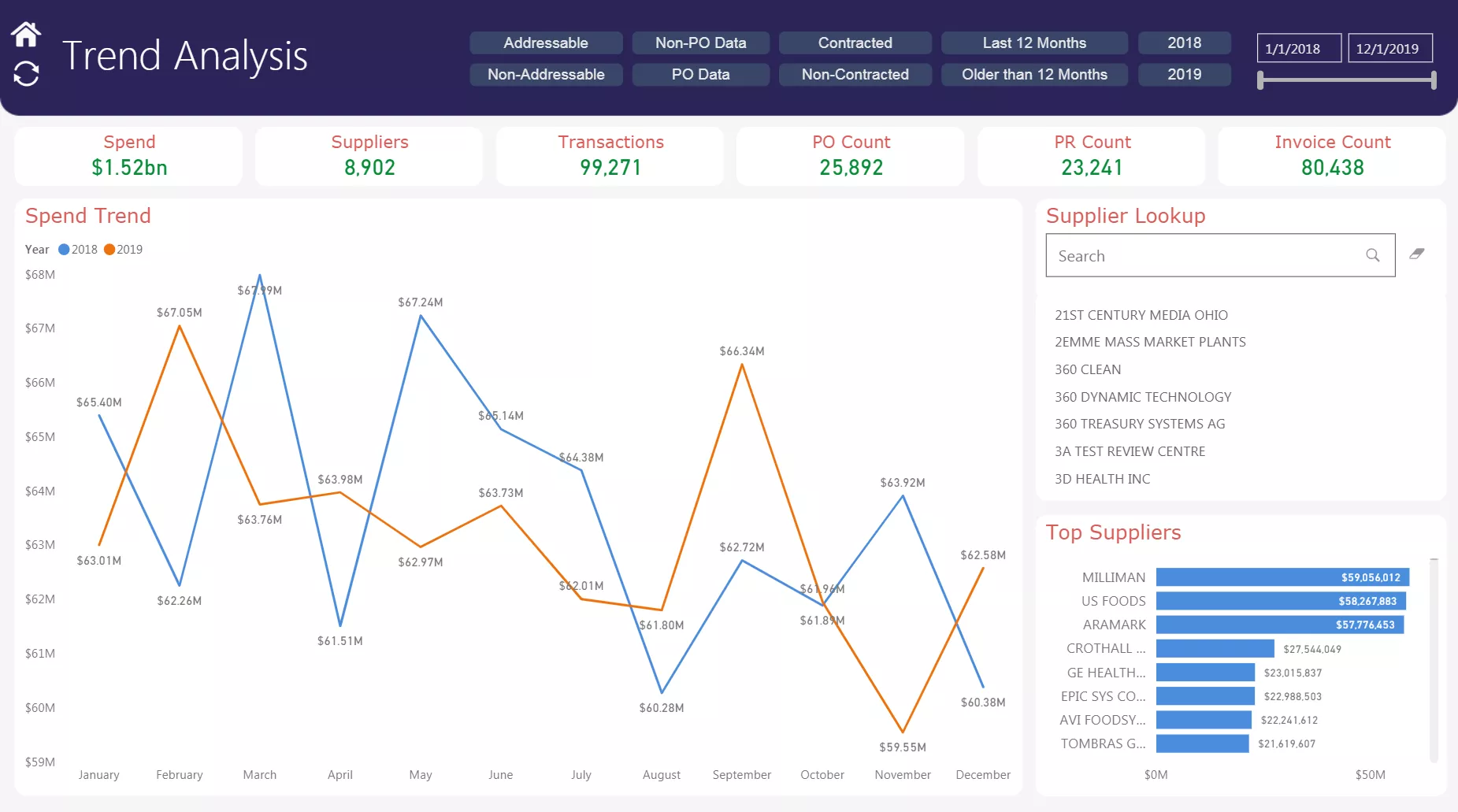

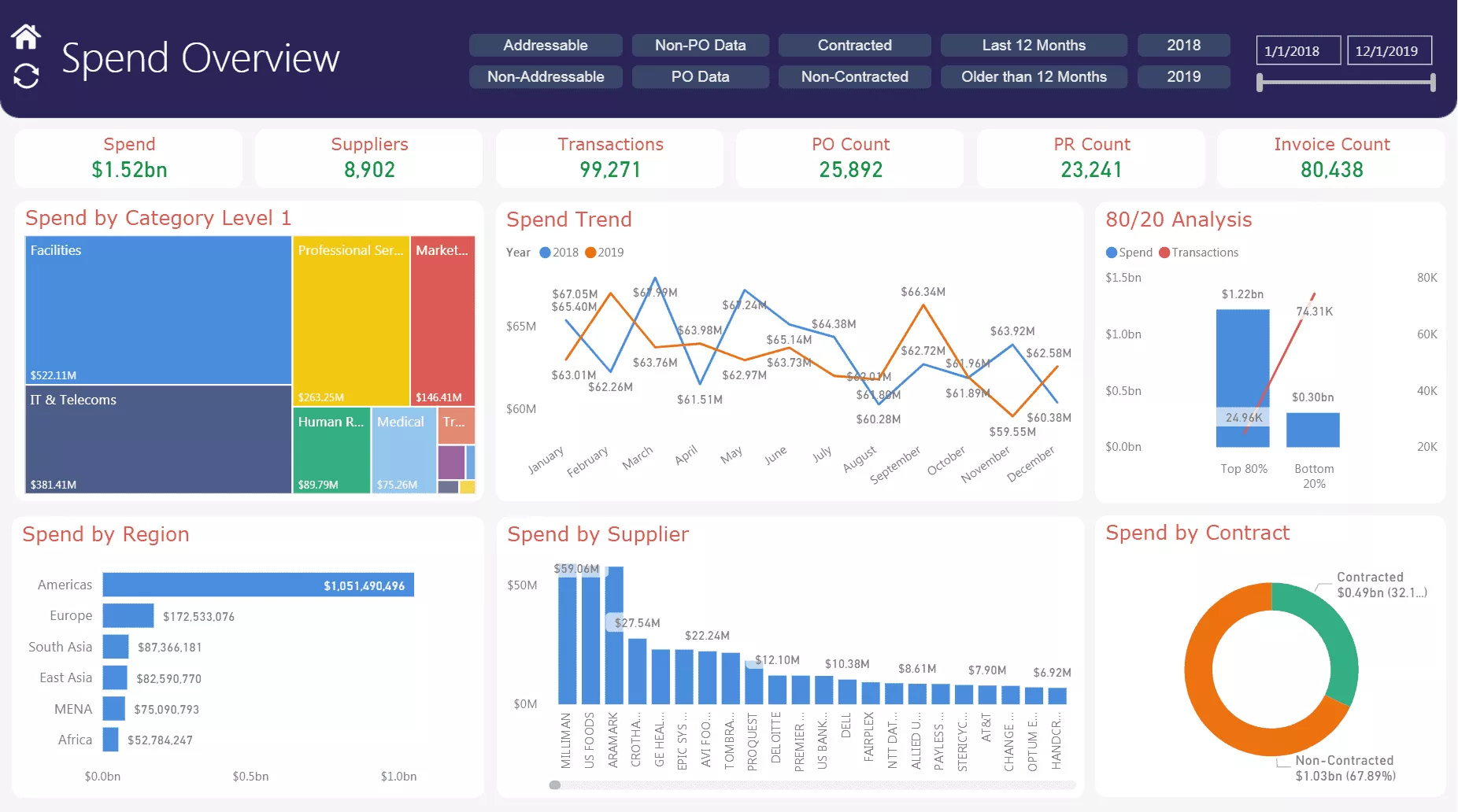

Spend Analysis:- With automatic classification, you can get a level 4+ view of your spending habits. Automatically computed KPIs and indicators let you track procurement performance and uncover insights.

Safe Harbor Sourcing:- Users can submit their RFx requests within the company’s requirements, utilizing vendors that have already been approved. This collects previously unaccounted-for spending, keeps buyers compliant, and minimizes procurement staff burden.

Order Management:- Start an RFQ process using Flip Requisitions to automate the laborious tasks of emailing suppliers, gathering answers, and rating offers.

Contracts Management:- Utilize your current contracts to gain insight into your procurement efficiency. Examine common words, what is covered by the contract and what isn’t, as well as the risk of non-compliance.

Conclusion

Simfoni’s Procurement professionals are ready to help you digitize and optimize your procurement. Simfoni teams are located globally and support small and largest corporations globally. Simfoni’s experience and expertise can help you make the most of your procurement process. Get in touch today.

Frequently Asked Question (FAQ)

For your help, we have created a list of answers to assist you more.

What is procurement?

Procurement is defined as a strategic process within an organization aimed at efficiently acquiring quality goods and services from suppliers in an ethical manner. This process is designed to help the organization achieve its business objectives, which typically include cost savings, time reduction, and improved profitability. In essence, procurement involves the entire lifecycle of acquiring goods or services, encompassing activities such as supplier selection, negotiation, purchase order issuance, receipt of goods, and payment processing. While the specific definition of procurement may vary from one organization to another, its fundamental purpose is to obtain competitively priced supplies that offer the best overall value to the company.

What is an example of procurement?

An illustration of procurement occurs when a manufacturing company procures essential raw materials. Examples can be steel or plastic, from a supplier. These materials are subsequently utilized in the production of the company’s goods.

What are the 3 primary procurement categories?

The three primary procurement categories include:

- Direct Procurement: This entails acquiring raw materials or components directly that is utilized in manufacturing.

- Indirect Procurement: It encompasses purchases of goods and services. These are not directly related to production, such as office supplies or IT services.

- Services Procurement: This centers on procuring services from external sources. For example, contracting services, legal counsel or consulting.

Why is procurement used?

Procurement is used to efficiently source and acquire goods and services from external providers. It helps organizations obtain what they need while considering factors like cost-effectiveness and quality.

What are the 7 stages of procurement?

The seven stages of procurement encompass:

- Identifying the need for goods or services.

- Selecting suitable suppliers.

- Negotiating contracts.

- Creating purchase orders.

- Handling invoicing.

- Inspecting received goods or services.

- Maintaining records for transparency and accountability.

What is the difference between procurement and purchasing?

Procurement is a comprehensive process that includes purchasing as one of its steps. Purchasing specifically refers to the act of buying goods or services, whereas procurement encompasses strategic planning, supplier selection, negotiation, and more.

What is KPI in procurement?

Key Performance Indicators (KPIs) in procurement are measurable metrics used to evaluate the effectiveness of the procurement process. Examples include cost savings, supplier performance, and on-time delivery.

What are the types of procurement?

Types of procurement include direct procurement (for materials), indirect procurement (for non-production items), and services procurement (for services needed by the organization).

What is the procurement cycle?

The procurement cycle is a systematic sequence of steps that organizations follow, from identifying a need for goods or services to finalizing payment and record-keeping.

What are the 10 steps of purchasing?

The ten steps of purchasing involve identifying needs, supplier selection, vendor assessment, negotiation, purchase order creation, goods receipt, inspection, invoicing, payment, and record-keeping.

What are the 5 R's of purchasing?

The 5 R’s of purchasing stand for obtaining the right quality, quantity, price, place, and time when acquiring goods or services.

Is procurement a project?

Procurement can be considered a project when it involves specific goals, timelines, and resource allocation for efficiently acquiring goods and services.

Which industry is procurement essential for?

Procurement is crucial across various industries, including manufacturing, healthcare, retail, and more, as it involves acquiring goods and services necessary for their operations.

What category does procurement fall under?

Procurement falls under the category of strategic management within an organization, focusing on optimizing the acquisition of goods and services to achieve business objectives.

How can organizations optimize their procurement processes?

To optimize procurement processes, organizations can leverage advanced technology, data analytics, establish strong supplier relationships, and implement cost-effective strategies to streamline operations, reduce expenses, and enhance efficiency.

Useful Resources

- Cost Reduction Strategies in Procurement.

- Effective Procure-to-Pay Process Guide (P2P Procurement).

- Guide to eProcurement software & Solutions.

- Guide to Manage Tail Spend and Improve the Bottom Line.

- Guide to Procurement Software & eProcurement Solution.

- Guide to Understanding Category Management in Procurement.

- Leveraging AI & Machine Learning in Procurement.

- Procurement Analytics & Implementation.

- Procurement Management - Key Steps and Roles.

- Procurement Marketplace - Reinventing Procurement

- Savings Tracking Process in Procurement.

- Source to Pay Process, Steps & Definition.

- Spend Analysis in Procurement: Importance, Process & Examples.

- Supplier Diversity in Procurement

- Sustainable Procurement - Importance & Best Practices

- Understanding the What, Why, & How of Strategic Sourcing.

- Procurement Auctions – How It Works, Example, and Risks.

- Supply Chain Management (SCM): How It Works and Why It Is Important

- What is Contract Management - Everything You Need to Know

- B2B Marketplace - The Ultimate Guide to Procurement Marketplace

- Spend Management - Importance & Best Practices On Business Spend Management Software & Solutions

- Strategic Sourcing – Ultimate Guide To Strategic Sourcing Processes

- Spend Cube – Ultimate Guide to Spend Cube Analysis

- Procurement Software - Automate Your Procurement Process