Manufacturing Procurement

A Complete Guide to Strategies, Tools & Best Practices.

Table of Contents

What is Manufacturing Procurement?

Manufacturing procurement refers to the activities required to acquire materials, parts, and services needed to produce finished products. This includes everything from raw materials like steel and plastic to components such as electronic circuits and packaging supplies.

Simfoni.com Tweet

Manufacturing procurement is a critical component in the production process, involving the acquisition of goods and services necessary for manufacturing operations. Understanding this subject is essential for anyone involved in supply chain management, purchasing, or production planning.

Manufacturing Procurement Solutions

Key Components of Manufacturing Procurement

- Sourcing

- Identifying potential suppliers who can provide the required materials or components.

- Evaluating suppliers based on quality, reliability, cost, and delivery capabilities.

- Purchasing

- Negotiating contracts with selected suppliers.

- Placing orders for goods or services based on demand forecasts.

- Supplier Management

- Building relationships with suppliers to ensure consistent quality and timely delivery.

- Monitoring supplier performance through metrics like lead time and defect rates.

- Inventory Management

- Managing stock levels of raw materials and components to avoid shortages while minimizing excess inventory costs.

- Implementing just-in-time (JIT) practices when appropriate to reduce waste.

- Cost Control

- Analyzing total costs associated with procurement decisions including purchase price, transportation costs, storage fees, etc.

- Seeking opportunities for cost reduction without compromising quality.

- Quality Assurance

- Ensuring that procured items meet specified standards before they enter the production process.

- Conducting inspections or audits as necessary.

- Sustainability Considerations

- Evaluating environmental impacts during sourcing decisions (e.g., choosing eco-friendly materials).

- Considering social responsibility factors related to supplier practices (e.g., labor conditions).

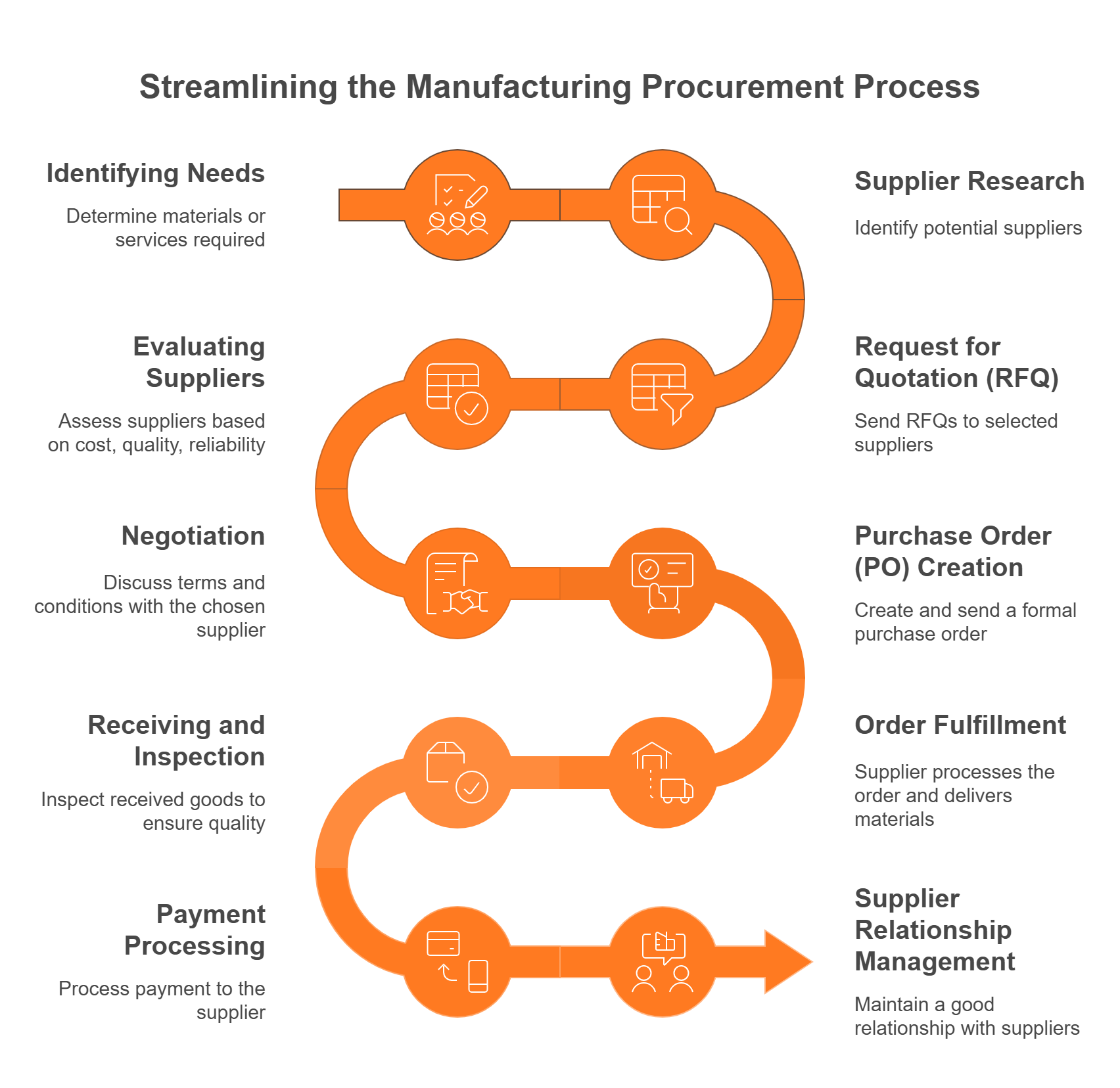

Steps in the Manufacturing Procurement Process

Understanding the Manufacturing Procurement Process

The manufacturing procurement process is a vital part of the supply chain. It involves acquiring the goods and services necessary for production. Let’s break down the key components of this process.

Key Steps in the Manufacturing Procurement Process

Identifying Needs

- Determine what materials or services are required for production.

- Example: A car manufacturer needs steel, rubber, and electronics for vehicle assembly.

Supplier Research

- Identify potential suppliers who can provide the needed materials.

- Example: Researching companies that produce high-quality steel or rubber.

Request for Quotation (RFQ)

- Send out RFQs to selected suppliers to get pricing and terms.

- Example: Asking multiple steel suppliers for their prices and delivery times.

Evaluating Suppliers

- Assess suppliers based on cost, quality, reliability, and delivery times.

- Example: Comparing the quotes received to determine which supplier offers the best value.

Negotiation

- Discuss terms and conditions with the chosen supplier to finalize the deal.

- Example: Negotiating a bulk discount for a large order of rubber tires.

Purchase Order (PO) Creation

- Create and send a formal purchase order to the supplier.

- Example: Issuing a PO that specifies the quantity, price, and delivery date for steel.

Order Fulfillment

- The supplier processes the order and delivers the materials.

- Example: The steel supplier ships the ordered steel to the manufacturing plant.

Receiving and Inspection

- Inspect the received goods to ensure they meet quality standards.

- Example: Checking the steel for any defects or damage upon arrival.

Payment Processing

- Process payment to the supplier as per the agreed terms.

- Example: Paying the supplier within 30 days of receiving the steel.

Supplier Relationship Management

- Maintain a good relationship with suppliers for future procurement needs.

- Example: Regularly communicating with the steel supplier to ensure timely deliveries.

Practical Example

Imagine you are managing the procurement for a furniture manufacturing company. Here’s how you would apply the steps:

- Identifying Needs: You realize you need high-quality wood and upholstery for your new sofa line.

- Supplier Research: You look for local and international suppliers who specialize in these materials.

- RFQ: You send out RFQs to these suppliers to gather pricing.

- Evaluating Suppliers: You compare the quality of wood samples received from different suppliers.

- Negotiation: You negotiate prices and delivery times with the best supplier.

- PO Creation: You create a purchase order for 100 units of wood and upholstery.

- Order Fulfillment: The supplier delivers the materials to your factory.

- Receiving and Inspection: You inspect the wood for quality and ensure it meets your standards.

- Payment Processing: You process the payment as per the agreed-upon terms.

- Supplier Relationship Management: You keep in touch with the supplier for future projects.

By following these steps, you can ensure a smooth procurement process that supports your manufacturing goals.

Importance of Effective Manufacturing Procurement

- Reduces Costs: Efficient procurement strategies help lower material costs which directly impacts overall profitability.

- Enhances Production Efficiency: Timely availability of high-quality inputs ensures smoother operations on assembly lines reducing downtimes due lack thereof!

- Improves Supplier Relationships: Strong communication fosters trust leading better collaboration over time resulting favorable outcomes when issues arise!

By understanding these aspects of manufacturing procurement thoroughly you will be well-equipped navigate complexities inherent within this vital area!

Key Principles of Manufacturing Procurement?

Understanding manufacturing procurement is essential for ensuring that the production process runs smoothly and efficiently. Here are the key principles:

1. Supplier Relationships

- Building Trust: Establishing strong relationships with suppliers can lead to better pricing and quality.

- Communication: Regular communication helps in aligning goals and expectations.

2. Cost Management

- Budgeting: Understand your budget constraints to make informed purchasing decisions.

- Total Cost of Ownership: Consider not just the purchase price but also maintenance, operation, and disposal costs.

3. Quality Assurance

- Standards Compliance: Ensure that suppliers meet industry standards and regulations.

- Quality Control: Implement checks to maintain product quality throughout the procurement process.

4. Inventory Management

- Just-In-Time (JIT): Reduce inventory costs by receiving goods only as they are needed in the production process.

- Safety Stock: Maintain a buffer to prevent production delays due to supply chain disruptions.

5. Market Analysis

- Demand Forecasting: Analyze market trends to anticipate future needs and adjust procurement strategies accordingly.

- Supplier Market Research: Evaluate potential suppliers based on reliability, financial stability, and capacity.

6. Sustainability and Ethics

- Responsible Sourcing: Choose suppliers who adhere to ethical practices and sustainability efforts.

- Environmental Impact: Consider the environmental implications of procurement decisions.

7. Technology Utilization

- E-Procurement Tools: Use software to streamline procurement processes and improve efficiency.

- Data Analytics: Leverage data to make informed decisions about suppliers and purchasing strategies.

By focusing on these principles, you can enhance the effectiveness of your manufacturing procurement process and contribute to the overall success of your production operations.

Types of Manufacturing Procurement

Understanding the different types of procurement in manufacturing is crucial for effective supply chain management. Here are the main types:

1. Direct Procurement

- Definition: This involves acquiring goods and services that are directly used in the production process.

- Examples:

- Raw materials like steel, plastic, or wood.

- Components such as engines or circuit boards that are assembled into the final product.

2. Indirect Procurement

- Definition: This refers to purchasing goods and services that are not directly tied to the production process but support the overall operations.

- Examples:

- Office supplies, IT equipment, and maintenance services.

- Cleaning services or facility management.

3. Strategic Procurement

- Definition: This focuses on long-term goals and building relationships with suppliers to create competitive advantages.

- Examples:

- Establishing partnerships with key suppliers for exclusive materials.

- Collaborating on product development with suppliers.

4. Tactical Procurement

- Definition: This involves short-term purchasing decisions that are often reactive to immediate needs.

- Examples:

- Ordering additional materials to fulfill a sudden increase in demand.

- Sourcing last-minute components for a production line.

5. Sustainable Procurement

- Definition: This emphasizes purchasing decisions that consider environmental and social impacts.

- Examples:

- Sourcing recycled materials.

- Partnering with suppliers who follow ethical labor practices.

6. Global Procurement

- Definition: This involves sourcing goods and services from international suppliers to leverage cost advantages or specific capabilities.

- Examples:

- Importing specialized machinery from Europe.

- Sourcing raw materials from countries with lower production costs.

7. Local Procurement

- Definition: This focuses on sourcing goods and services from local suppliers to support the local economy and reduce transportation costs.

- Examples:

- Buying raw materials from nearby farms or manufacturers.

- Engaging local service providers for maintenance.

Understanding these types of procurement can help manufacturers streamline their operations, reduce costs, and improve product quality. Each type serves a unique purpose and can be strategically utilized based on the company’s goals and market conditions.

Manufacturing Procurement Strategies

Understanding Manufacturing Procurement Strategies

Manufacturing procurement strategies are essential for ensuring that a company efficiently acquires the materials and services needed for production. These strategies help in reducing costs, improving quality, and ensuring timely delivery. Let’s break down some key strategies you can use in manufacturing procurement.

1. Cost-Effective Sourcing

- Bulk Purchasing: Buying in large quantities can lead to discounts and lower per-unit costs.

- Supplier Negotiation: Building relationships with suppliers can lead to better pricing and terms.

- Local Sourcing: Reducing transportation costs and lead times by sourcing materials locally.

2. Supplier Relationship Management

- Long-Term Partnerships: Establishing long-term relationships with suppliers can enhance reliability and quality.

- Performance Reviews: Regularly assessing supplier performance to ensure they meet quality and delivery standards.

- Collaborative Planning: Working closely with suppliers to forecast demand and adjust orders accordingly.

3. Just-In-Time (JIT) Procurement

- Minimized Inventory: Reducing inventory levels to lower holding costs and waste.

- Timely Deliveries: Coordinating with suppliers to ensure materials arrive just as they are needed in the production process.

- Flexibility: Adapting quickly to changes in demand without overcommitting to stock.

4. Technology Utilization

- E-Procurement Systems: Using online platforms to streamline the purchasing process and improve efficiency.

- Data Analytics: Analyzing purchasing data to identify trends, optimize orders, and reduce costs.

- Automation: Implementing automated systems to manage inventory and orders, reducing human error.

5. Sustainability and Ethical Sourcing

- Eco-Friendly Materials: Choosing suppliers who provide sustainable materials to reduce environmental impact.

- Fair Labor Practices: Ensuring that suppliers adhere to ethical labor practices.

- Supply Chain Transparency: Maintaining transparency in sourcing to build trust with consumers.

6. Risk Management

- Diversifying Suppliers: Avoiding reliance on a single supplier to mitigate risks of disruptions.

- Contingency Planning: Developing backup plans to address potential supply chain disruptions.

- Market Analysis: Keeping abreast of market trends and potential risks that could impact procurement.

By implementing these manufacturing procurement strategies, you can improve your procurement processes, enhance supplier relationships, and ultimately contribute to the overall success of your manufacturing operations. Consider which strategies align best with your current knowledge and context, and start applying them in practical scenarios to see their benefits firsthand!

Supplier Evaluation and Selection

Supplier evaluation and selection is a critical component of the manufacturing procurement process. It involves identifying, assessing, and choosing suppliers who can provide the necessary goods or services to meet production needs effectively. The goal is to ensure that selected suppliers align with the company’s quality standards, cost objectives, delivery requirements, and overall strategic goals.

Importance of Supplier Evaluation and Selection

Quality Assurance: Selecting reliable suppliers helps maintain product quality. Poor supplier performance can lead to defects in products which may affect customer satisfaction.

Cost Efficiency: Evaluating suppliers allows organizations to compare costs effectively. By selecting cost-efficient suppliers without compromising on quality, companies can optimize their procurement budgets.

Risk Management: A thorough evaluation helps identify potential risks associated with supplier relationships—such as financial instability or supply chain disruptions—and mitigates them before they impact operations.

Long-term Relationships: Building strong partnerships with evaluated suppliers fosters collaboration and innovation over time, leading to better terms in future negotiations.

Criteria for Supplier Selection

When evaluating potential suppliers, several criteria should be considered:

Financial Stability: Assessing a supplier’s financial health ensures they have the resources needed to fulfill contracts consistently.

Quality Standards: Suppliers should adhere to industry-specific quality certifications (e.g., ISO 9001) that demonstrate their commitment to maintaining high standards.

Delivery Performance: Timeliness is crucial in manufacturing; thus evaluating past delivery records helps gauge whether a supplier can meet deadlines reliably.

Technical Capability: Suppliers must possess the necessary technology and expertise relevant to your specific needs (e.g., advanced machinery for precision parts).

Reputation & References: Investigating a supplier’s reputation through references from other clients provides insight into their reliability and service level.

Evaluation Techniques

To systematically evaluate potential suppliers, various techniques can be employed:

Scorecards:

- Develop scorecards that assign weights based on importance (e.g., 40% quality, 30% price). Each supplier is rated against these criteria resulting in an overall score for comparison.

Example: If three different manufacturers are being considered for steel supplies:

- Manufacturer A scores 85/100,

- Manufacturer B scores 75/100,

- Manufacturer C scores 90/100,

Based on this scoring system alone, Manufacturer C would be favored due to its higher rating despite potentially being slightly more expensive.

Site Visits & Audits:

- Conducting site visits offers firsthand insights into operational capabilities while audits assess compliance with agreed-upon standards such as safety regulations or environmental practices.

Request for Proposal (RFP):

- Sending out RFPs allows you not only to gather pricing information but also understand how well each vendor addresses your specific needs through proposals tailored accordingly.

Supplier Audits

Regular audits of selected suppliers help ensure ongoing compliance with contractual obligations:

- These audits might include reviewing production processes or conducting inspections on-site.

Example: If you are sourcing components from an overseas manufacturer known for low prices but questionable practices—an audit could uncover issues like labor violations or inadequate safety measures that could jeopardize both supply stability and company reputation.*

In summary, effective supplier evaluation and selection is essential within manufacturing procurement as it directly impacts product quality, cost management, risk mitigation strategies—and ultimately influences business success through sustainable partnerships focused on mutual growth!

Procurement Technologies

Procurement technologies play a vital role in streamlining and enhancing the efficiency of procurement processes within manufacturing. These technologies not only automate routine tasks but also provide valuable insights that help organizations make informed decisions, manage supplier relationships, and optimize costs. Understanding these technologies is crucial for anyone involved in manufacturing procurement.

Importance of Procurement Technologies

- Efficiency Improvement: Automation reduces manual work, allowing procurement professionals to focus on strategic activities rather than repetitive tasks.

- Data-Driven Decisions: Advanced analytics enable organizations to analyze purchasing patterns, supplier performance, and market trends.

- Cost Savings: Technology can identify cost-saving opportunities through better negotiation strategies and supplier management.

- Enhanced Collaboration: Tools facilitate communication among stakeholders, including suppliers, internal teams, and other departments.

Key Types of Procurement Technologies

E-Procurement Systems

- E-procurement systems are online platforms that allow companies to manage their purchasing activities electronically.

- Example: A manufacturing company might implement an e-procurement system like SAP Ariba or Coupa to streamline their purchase requisition process. Employees can easily request materials or services online while ensuring compliance with organizational policies.

- This category includes software solutions designed specifically for managing various aspects of the procurement process such as sourcing, contract management, and spend analysis.

- Example: A firm may use Oracle Procurement Cloud to track spending across different categories and identify areas where they can negotiate better terms with suppliers based on historical data.

Blockchain in Procurement

- Blockchain technology offers transparency by creating immutable records of transactions between buyers and suppliers.

- It enhances trust by providing an auditable trail that verifies product origins or transaction details.

- Example: In the automotive industry, manufacturers could utilize blockchain to trace parts from suppliers back through the supply chain to ensure quality standards are met consistently.

Supplier Relationship Management (SRM) Tools

- SRM tools help businesses maintain effective communication with their suppliers while assessing performance metrics regularly.

- They often include features for tracking key performance indicators (KPIs), conducting surveys for feedback, and managing contracts effectively.

- Example: A consumer electronics manufacturer might employ an SRM tool like Jaggaer to monitor supplier delivery times against agreed-upon SLAs (Service Level Agreements).

Spend Analysis Tools

- Spend analysis tools aggregate purchasing data from various sources within an organization to identify trends and opportunities for savings.

- They help decision-makers understand where money is being spent most heavily so they can strategize accordingly.

- Example: Using a spend analysis tool like Zycus allows a manufacturing firm to visualize its spending patterns over time—helping them spot high-spending areas ripe for renegotiation or bulk buying agreements.

Artificial Intelligence (AI) & Machine Learning

- AI-powered solutions enhance procurement processes by predicting demand fluctuations or optimizing inventory levels based on real-time data analysis.

- For instance:

- An AI-driven tool could forecast which raw materials will be needed more during peak production seasons based on historical sales data.

Robotic Process Automation (RPA) – RPA automates rule-based tasks that involve structured data processing without human intervention—a game changer in reducing operational costs associated with manual entry errors or delays in processing orders efficiently. ForExample: Utilizing RPA bots helps automate invoice matching against purchase orders quickly; this minimizes payment delays due inaccuracies caused by human error during document handling.

Incorporating advanced procurement technologies into manufacturing operations has transformed how businesses approach sourcing materials and managing supplier relationships today—leading towards streamlined workflows alongside improved financial outcomes! By leveraging these tools effectively across all stages—from identifying needs through contract negotiations—you’ll position your organization competitively within its respective marketplace while optimizing overall resource utilization!

Legal and Ethical Considerations

In manufacturing procurement, understanding legal and ethical considerations is crucial for ensuring compliance, fostering trust with suppliers, and maintaining a positive reputation. This topic encompasses various aspects that guide how organizations conduct their purchasing activities responsibly and legally.

1. Contract Law

Contract law forms the backbone of procurement transactions. It governs the agreements made between buyers and suppliers, outlining terms such as pricing, delivery schedules, quality standards, and payment conditions.

- Practical Example: When a manufacturer enters into a contract with a supplier for raw materials, they must ensure that all terms are clearly defined to prevent disputes over what was agreed upon. For instance, specifying penalties for late deliveries can protect the manufacturer’s production schedule.

2. Ethical Sourcing

Ethical sourcing involves selecting suppliers based on their adherence to ethical practices concerning labor rights, environmental impact, and fair trade principles. Companies are increasingly held accountable not just for what they purchase but also how it affects society at large.

- Practical Example: A clothing manufacturer may choose to source cotton from farms that guarantee fair wages and safe working conditions for workers rather than opting for cheaper alternatives that exploit laborers. This commitment can enhance brand loyalty among consumers who prioritize ethical consumption.

3. Compliance and Regulations

Manufacturers must navigate numerous regulations governing procurement processes at local, national, and international levels. These laws cover everything from anti-corruption measures to import/export restrictions.

- Practical Example: A company importing machinery from another country must comply with customs regulations which may require specific documentation proving that the equipment meets safety standards in its home country before it can be sold or used in production.

4. Transparency in Procurement Practices

Transparency refers to making procurement processes clear to stakeholders including employees, suppliers, investors, and customers. Being transparent helps build trust within supply chains.

- Practical Example: If a manufacturer publicly shares its supplier list along with criteria used for selection (like sustainability practices), it demonstrates accountability which can positively influence public perception while reducing risks related to unethical behavior by hidden suppliers.

5. Conflict of Interest Management

Procurement professionals should avoid situations where personal interests conflict with professional duties—such as favoring a friend’s business when awarding contracts without proper evaluation procedures in place.

- Practical Example: If an employee has family ties to one of the potential suppliers bidding on a contract deal but does not disclose this relationship during evaluations or discussions about supplier selection – this could lead both parties into legal trouble if discovered later on due diligence checks by auditors or regulators.

Navigating legal frameworks while adhering strictly to ethical guidelines is essential in manufacturing procurement today more than ever due largely because consumers demand greater responsibility from brands regarding social issues like labor rights & environmental impacts associated with product sourcing decisions! By implementing robust systems around these considerations – manufacturers not only mitigate risks but also position themselves favorably against competitors who might overlook them altogether!

Cost Management in Manufacturing Procurement

Cost management in manufacturing procurement is essential for ensuring that a company operates efficiently and remains competitive. It involves planning, monitoring, and controlling costs associated with acquiring goods and services needed for manufacturing processes. Let’s break it down into key components:

Key Components of Cost Management

Budgeting

- Establishing a budget for procurement activities.

- Example: A manufacturing company sets a budget of $100,000 for raw materials for the upcoming quarter.

Cost Analysis

- Analyzing costs associated with suppliers, materials, and services.

- Example: Comparing prices from different suppliers to find the best deal for steel used in production.

Supplier Negotiation

- Negotiating terms and prices with suppliers to reduce costs.

- Example: A company negotiates a bulk purchase discount with a supplier for ordering larger quantities of components.

Total Cost of Ownership (TCO)

- Considering all costs associated with a product, not just the purchase price.

- Example: Evaluating the long-term costs of a machine, including maintenance, training, and energy consumption, rather than just its initial cost.

Performance Monitoring

- Continuously monitoring procurement activities to ensure they align with the budget.

- Example: Reviewing monthly procurement reports to check if spending is within the allocated budget.

Cost Reduction Strategies

- Implementing strategies to reduce costs without compromising quality.

- Example: Streamlining the procurement process by using technology to automate orders, reducing labor costs.

Practical Steps to Implement Cost Management

Set Clear Objectives

- Define what you want to achieve with your cost management efforts.

Gather Data

- Collect data on current procurement costs and supplier performance.

Analyze the Data

- Use the data to identify areas where costs can be reduced.

Engage Stakeholders

- Involve key stakeholders in the decision-making process to ensure buy-in and support.

Monitor and Adjust

- Regularly review your cost management strategies and make adjustments as necessary.

By focusing on these components and steps, you can effectively manage costs in manufacturing procurement, leading to improved profitability and operational efficiency.

Sustainable Procurement in Manufacturing Procurement

Sustainable procurement in manufacturing refers to the process of sourcing goods and services in a way that considers environmental, social, and economic impacts. This means not just looking for the lowest price but also considering the long-term effects of purchasing decisions.

Key Concepts of Sustainable Procurement

Environmental Impact

- Reducing Waste: Choosing suppliers who minimize packaging or use recyclable materials.

- Energy Efficiency: Sourcing products that are energy-efficient or produced using renewable energy sources.

Social Responsibility

- Fair Labor Practices: Ensuring suppliers provide fair wages and safe working conditions for their employees.

- Community Engagement: Supporting local suppliers and businesses to boost the local economy.

Economic Viability

- Cost-Effectiveness: While sustainable products may have a higher upfront cost, they can lead to savings over time through efficiency and durability.

- Long-Term Relationships: Building partnerships with suppliers who share sustainable values can lead to better quality and reliability.

Practical Examples of Sustainable Procurement

Example 1: Sourcing Materials

- A manufacturing company decides to source recycled aluminum for its products instead of virgin aluminum. This choice reduces the environmental impact associated with mining and processing raw materials.

Example 2: Supplier Selection

- When selecting a supplier for machinery, a company chooses one that uses renewable energy sources in its manufacturing process, thus reducing the carbon footprint associated with production.

Example 3: Packaging Choices

- A business opts for biodegradable packaging for its products, which not only appeals to environmentally conscious consumers but also reduces landfill waste.

Steps to Implement Sustainable Procurement

Assess Current Practices

- Evaluate existing procurement processes and identify areas for improvement regarding sustainability.

Set Clear Goals

- Define what sustainability means for your organization and set measurable targets.

Engage Stakeholders

- Involve team members, suppliers, and customers in discussions about sustainable practices to gather insights and build support.

Monitor and Report

- Regularly track progress towards sustainability goals and communicate results to stakeholders.

Continuous Improvement

- Stay updated on sustainable practices and technologies to continually enhance procurement strategies.

By integrating sustainable procurement into manufacturing processes, organizations can not only contribute positively to the environment and society but also potentially lower costs and improve their brand reputation over time.

Risk Management in Manufacturing Procurement

Risk management in manufacturing procurement involves identifying, assessing, and mitigating risks that can affect the procurement process. Here’s a breakdown of what this entails:

Key Concepts of Risk Management in Procurement

Identifying Risks

- Supplier Reliability: Assessing if suppliers can deliver on time and meet quality standards.

- Market Fluctuations: Understanding how changes in market conditions can affect prices and availability.

- Regulatory Compliance: Ensuring that suppliers adhere to industry regulations and standards.

Assessing Risks

- Impact Analysis: Evaluating how a risk could affect the procurement process, such as delays or increased costs.

- Probability Assessment: Determining the likelihood of a risk occurring, such as a supplier going out of business.

Mitigating Risks

- Diversifying Suppliers: Working with multiple suppliers to reduce dependency on a single source.

- Contractual Safeguards: Including clauses in contracts that protect against potential risks, such as penalties for late delivery.

- Regular Audits: Conducting audits to assess supplier performance and compliance regularly.

Practical Examples

Supplier Reliability: If you rely on a single supplier for a critical component, consider finding a backup supplier. For instance, if you manufacture bicycles, having multiple suppliers for tires can prevent production delays if one supplier faces issues.

Market Fluctuations: If the price of steel suddenly rises due to global demand, you might want to negotiate long-term contracts with suppliers to lock in prices. This helps in budgeting and reducing the impact of price hikes.

Regulatory Compliance: If your manufacturing process requires specific certifications (like ISO), ensure that your suppliers have these certifications. Regularly check their compliance to avoid legal issues later.

Effective risk management in manufacturing procurement is essential for ensuring smooth operations and maintaining quality. By identifying, assessing, and mitigating risks, you can create a resilient procurement strategy that supports your manufacturing goals.

Trends in Manufacturing Procurement

Manufacturing procurement is rapidly evolving due to technological advancements, market dynamics, and changing consumer expectations. Understanding the current trends is essential for organizations to remain competitive and efficient. Here’s an extensive overview of key trends shaping manufacturing procurement today.

1. Digital Transformation

Digital transformation refers to integrating digital technologies into all areas of a business, fundamentally changing how operations are conducted and value is delivered.

Example: Many companies are adopting cloud-based solutions that allow real-time data sharing between suppliers and manufacturers. For instance, a manufacturer can use a centralized platform where suppliers update their inventory levels instantly, enabling better demand forecasting.

Benefits: Enhanced visibility leads to improved decision-making processes, reduced lead times, and increased operational efficiency.

2. Data-Driven Procurement

Data analytics plays a crucial role in modern procurement strategies by providing insights that drive smarter decisions.

Example: A company may leverage advanced analytics tools to analyze historical purchasing data alongside market trends to identify optimal buying patterns or forecast future needs more accurately.

Benefits: This trend allows businesses to optimize their supply chains by reducing costs and improving supplier performance through informed choices based on empirical evidence rather than intuition alone.

3. Collaborative Procurement

Collaborative procurement involves multiple organizations working together towards common purchasing goals which can lead to economies of scale.

Example: Small manufacturers may band together to negotiate bulk purchases from suppliers, thereby obtaining better pricing than they could individually achieve.

Benefits: By pooling resources and leveraging collective bargaining power, companies can reduce costs while also fostering stronger relationships with suppliers through shared interests.

4. Sustainability Focus

Sustainable practices have become increasingly important as consumers demand environmentally friendly products and ethical sourcing practices from companies they support.

Example: A manufacturer might implement green procurement policies that prioritize sourcing materials from eco-friendly suppliers or those who demonstrate sustainable practices—like using recycled materials in their production processes.

Benefits: Not only does this align with corporate social responsibility (CSR) objectives but it also enhances brand reputation among environmentally conscious consumers leading potentially to increased sales.

5. Automation in Procurement Processes

Automation technology streamlines various aspects of the procurement process—from order placement to invoice processing—reducing manual errors and increasing efficiency across the board.

Example: E-procurement systems automate routine tasks such as purchase order creation or invoice approvals using predefined workflows; thus freeing up employees’ time for strategic activities like supplier relationship management or contract negotiations.

Benefits: Automation reduces cycle times significantly while allowing teams greater focus on value-added activities rather than administrative tasks.

6. Blockchain Technology

Blockchain technology offers transparency and security within the supply chain by providing an immutable ledger for transactions involving goods and services purchased throughout the supply chain journey.

Example: In industries like pharmaceuticals where traceability is critical due regulatory requirements; blockchain enables tracking every transaction associated with a drug’s manufacturing process ensuring authenticity at each stage.

Benefits: This not only mitigates risks related fraud but also builds trust among stakeholders as everyone has access verified information about product origins along its journey through the supply chain.

Staying abreast of these trends helps manufacturers adapt their procurement strategies effectively while enhancing efficiency throughout operations overall . As digital tools continue evolving alongside shifting consumer preferences , embracing these changes will be vital for sustaining competitive advantage within today’s fast-paced marketplace .

Conclusion:

In summary, manufacturing procurement serves as a backbone for successful operations within any manufacturing entity. By understanding key components such as strategic sourcing, supplier management, cost considerations, risk assessment, sustainability efforts, and technology integration; businesses can position themselves competitively in today’s dynamic market landscape. Ultimately it leads not just towards achieving immediate needs but fosters long-term growth through effective resource management strategies tailored around specific organizational goals.

Frequently Asked Questions on Manufacturing Procurement

Strategic sourcing is a systematic process that helps organizations optimize their procurement activities. Here are some key benefits:

1. Cost Reduction

- Bulk Purchasing: By negotiating long-term contracts or bulk purchases, companies can often secure lower prices.

- Supplier Competition: Encouraging competition among suppliers can lead to better pricing and terms.

2. Improved Supplier Relationships

- Collaboration: Building strong partnerships with suppliers can lead to better communication and collaboration.

- Trust: Long-term relationships foster trust, which can result in more favorable terms and conditions.

3. Quality Improvement

- Supplier Evaluation: Strategic sourcing involves assessing suppliers for quality, ensuring that only the best materials are used in manufacturing.

- Continuous Improvement: Working closely with suppliers can lead to innovations in quality and efficiency.

4. Risk Management

- Diversification: By sourcing from multiple suppliers, companies can mitigate risks associated with supply chain disruptions.

- Market Insights: Strong supplier relationships can provide valuable insights into market trends and potential risks.

5. Enhanced Innovation

- Access to Expertise: Suppliers often have specialized knowledge and can offer innovative solutions to improve products or processes.

- Joint Development: Collaborating with suppliers on new products can lead to faster development cycles and improved offerings.

6. Better Compliance and Sustainability

- Regulatory Compliance: A strategic approach ensures that suppliers adhere to industry regulations and standards.

- Sustainable Practices: Focusing on sustainable sourcing can enhance a company’s reputation and reduce environmental impact.

7. Increased Efficiency

- Streamlined Processes: A strategic sourcing plan can streamline procurement processes, reducing lead times and administrative burdens.

- Technology Integration: Utilizing technology in sourcing can improve data management and analytics, leading to better decision-making.

By understanding and implementing strategic sourcing, companies in the manufacturing sector can significantly enhance their procurement processes, leading to improved overall performance and competitiveness.

Manufacturing procurement involves sourcing and acquiring materials and services needed for production. While it is crucial for operational efficiency, there are several challenges that professionals in this field often encounter. Here are some of the most common challenges:

1. Supplier Reliability

- Inconsistent Quality: Suppliers may not always deliver materials that meet the required specifications.

- Delivery Delays: Late shipments can disrupt production schedules.

2. Cost Control

- Price Fluctuations: Changes in raw material prices can impact budgeting and profitability.

- Hidden Costs: Additional expenses such as shipping, taxes, and tariffs can arise unexpectedly.

3. Inventory Management

- Overstocking: Holding too much inventory can lead to increased storage costs and waste.

- Stockouts: Running out of essential materials can halt production and lead to lost sales.

4. Supplier Relationships

- Communication Issues: Lack of clear communication can lead to misunderstandings and errors.

- Negotiation Challenges: Achieving favorable terms requires strong negotiation skills and relationship management.

5. Regulatory Compliance

- Adhering to Standards: Ensuring that suppliers meet industry regulations can be complex and time-consuming.

- Sustainability Concerns: Increasing pressure to source materials ethically and sustainably can complicate procurement decisions.

6. Technological Integration

- Adopting New Systems: Implementing procurement software can be challenging, especially for teams used to traditional methods.

- Data Management: Effectively analyzing procurement data to make informed decisions requires the right tools and skills.

7. Market Volatility

- Economic Changes: Fluctuations in the economy can affect availability and pricing of materials.

- Geopolitical Factors: Political instability in supplier countries can disrupt supply chains.

Understanding these challenges can help you develop strategies to mitigate risks and improve procurement processes in manufacturing. For instance, building strong relationships with reliable suppliers can enhance communication and ensure timely deliveries, while utilizing technology can streamline inventory management.

Technology has revolutionized various aspects of manufacturing procurement, making it more efficient, transparent, and cost-effective. Here are several ways technology can enhance these processes:

1. Automation of Procurement Tasks

- Streamlining Processes: Automation tools can handle repetitive tasks such as purchase order creation, invoice processing, and supplier management.

- Example: Using software to automatically generate purchase orders when inventory levels reach a certain threshold.

2. Data Analytics

- Informed Decision-Making: Advanced analytics can provide insights into spending patterns, supplier performance, and market trends.

- Example: Analyzing past purchase data to identify the best times to buy materials at lower prices.

3. Supplier Relationship Management (SRM) Systems

- Improved Communication: SRM systems facilitate better communication and collaboration with suppliers.

- Example: Using a centralized platform where suppliers can submit invoices, track orders, and communicate directly with procurement teams.

4. E-Procurement Platforms

- Simplified Purchasing: E-procurement solutions allow companies to manage their procurement processes online, making it easier to source suppliers and products.

- Example: Implementing an online marketplace where employees can request materials from approved suppliers.

5. Blockchain Technology

- Enhanced Transparency: Blockchain provides a secure and transparent way to track transactions and ensure the authenticity of materials.

- Example: Using blockchain to verify the origin of raw materials, ensuring they meet quality standards.

6. Artificial Intelligence (AI) and Machine Learning

- Predictive Analytics: AI can analyze vast amounts of data to predict future procurement needs and trends.

- Example: AI algorithms predicting when to reorder materials based on historical usage patterns and upcoming projects.

7. Mobile Technology

- On-the-Go Access: Mobile applications allow procurement professionals to manage tasks from anywhere, improving responsiveness.

- Example: Using a mobile app to approve purchase orders or check inventory levels while on the factory floor.

8. Cloud Computing

- Centralized Data Storage: Cloud-based solutions enable easy access to procurement data from anywhere, fostering collaboration across teams.

- Example: Storing procurement documents and data in the cloud so that team members can access them in real-time, regardless of their location.

By leveraging these technological advancements, manufacturing procurement processes can become more efficient, reduce costs, and improve overall supply chain management.

Data analytics plays a crucial role in improving decision-making in manufacturing procurement by providing insights that help organizations optimize their processes, reduce costs, and enhance efficiency. Here’s how:

1. Improved Supplier Selection

- Data-Driven Evaluations: Analyze supplier performance metrics such as delivery times, quality ratings, and pricing history.

- Risk Assessment: Use historical data to assess potential risks associated with suppliers, helping to avoid disruptions.

2. Cost Reduction

- Spend Analysis: Examine purchasing data to identify areas where costs can be reduced.

- Negotiation Leverage: Utilize data on market trends and supplier pricing to negotiate better contracts.

3. Inventory Management

- Demand Forecasting: Analyze past usage patterns and market trends to predict future demand, helping to maintain optimal inventory levels.

- Just-in-Time Procurement: Use data to implement just-in-time strategies, reducing holding costs and minimizing waste.

4. Performance Monitoring

- KPI Tracking: Establish key performance indicators (KPIs) for procurement processes and use analytics to monitor performance over time.

- Continuous Improvement: Identify areas for improvement through data analysis, enabling ongoing enhancements to procurement strategies.

5. Enhanced Collaboration

- Information Sharing: Utilize data analytics to facilitate better communication and collaboration between procurement teams and other departments.

- Cross-Functional Insights: Leverage data from different areas (e.g., production, sales) to make more informed procurement decisions.

6. Market Trend Analysis

- Competitive Analysis: Analyze market data to understand competitors’ strategies and adjust procurement practices accordingly.

- Supplier Market Trends: Stay informed about changes in supplier markets, such as price fluctuations or availability issues.

7. Sustainability Initiatives

- Eco-Friendly Procurement: Use data to assess the environmental impact of suppliers and choose more sustainable options.

- Compliance Monitoring: Track compliance with sustainability regulations and standards through data analytics.

Practical Example

Imagine a manufacturing company that produces electronic devices. By implementing data analytics, the procurement team can analyze past purchasing data to identify a supplier that consistently delivers high-quality components on time. They can then use this information to negotiate better pricing and terms. Additionally, by forecasting demand based on historical sales data, they can adjust their orders to ensure they have just the right amount of inventory, reducing excess stock and associated costs.

In summary, leveraging data analytics in manufacturing procurement empowers organizations to make more informed, strategic decisions that can lead to significant improvements in efficiency, cost savings, and overall performance.

Negotiating contracts with suppliers is a critical aspect of manufacturing procurement. Here are some best practices to ensure effective negotiations:

1. Preparation and Research

- Understand Your Needs: Clearly define what you need from the supplier, including quality, quantity, delivery timelines, and pricing.

- Market Research: Research the market to know the average prices and terms that other companies are getting. This knowledge can empower your negotiation.

2. Build Relationships

- Establish Rapport: Develop a good relationship with suppliers. Trust can lead to better terms and cooperation.

- Communicate Openly: Share your goals and challenges with the supplier. Transparency can foster collaboration.

3. Set Clear Objectives

- Define Key Terms: Know what terms are most important to you—price, delivery schedules, payment terms, etc.

- Prioritize Needs vs. Wants: Identify which terms are non-negotiable and which ones you can compromise on.

4. Leverage Competition

- Multiple Quotes: Obtain quotes from multiple suppliers. This not only gives you options but also strengthens your negotiating position.

- Highlight Alternatives: Let suppliers know you have other options, which can motivate them to offer better terms.

5. Be Professional and Respectful

- Maintain Professionalism: Approach negotiations with a professional demeanor. Respect can go a long way in securing favorable terms.

- Listen Actively: Pay attention to the supplier’s needs and concerns. This can lead to a more collaborative approach.

6. Negotiate Win-Win Solutions

- Find Common Ground: Look for solutions that benefit both parties. This can lead to a long-term partnership.

- Be Creative: If price is a sticking point, consider negotiating other terms, such as longer payment periods or bulk discounts.

7. Document Everything

- Written Agreements: Ensure all agreed terms are documented in the contract to avoid misunderstandings later.

- Review the Contract: Carefully review the contract before signing to ensure all terms are clearly defined and agreed upon.

8. Follow Up

- Maintain Communication: After the contract is signed, keep the lines of communication open to address any issues that arise.

- Evaluate Performance: Regularly assess the supplier’s performance against the contract terms to ensure compliance.

By following these best practices, you can enhance your negotiation skills and establish strong, beneficial relationships with your suppliers in the manufacturing sector.

Resources

- Cost Reduction Strategies in Procurement.

- Effective Procure-to-Pay Process Guide (P2P Procurement).

- Guide to eProcurement software & Solutions.

- Guide to Manage Tail Spend and Improve the Bottom Line.

- Guide to Procurement Software & eProcurement Solution.

- Guide to Understanding Category Management in Procurement.

- Leveraging AI & Machine Learning in Procurement.

- Procurement Analytics & Implementation.

- Procurement Management - Key Steps and Roles.

- Procurement Marketplace - Reinventing Procurement

- Savings Tracking Process in Procurement.

- Source to Pay Process, Steps & Definition.

- Spend Analysis in Procurement: Importance, Process & Examples.

- Supplier Diversity in Procurement

- Sustainable Procurement - Importance & Best Practices

- Understanding the What, Why, & How of Strategic Sourcing.

- Procurement Auctions – How It Works, Example, and Risks.

- Supply Chain Management (SCM): How It Works and Why It Is Important

- What is Contract Management - Everything You Need to Know

- B2B Marketplace - The Ultimate Guide to Procurement Marketplace

- Spend Management - Importance & Best Practices On Business Spend Management Software & Solutions

- Strategic Sourcing – Ultimate Guide To Strategic Sourcing Processes

- Spend Cube – Ultimate Guide to Spend Cube Analysis

- Procurement Software - Automate Your Procurement Process